It is well known the National Training Center (NTC) can challenge and stress maintenance and sustainment systems. Following a rigorous training cycle 1st Battalion, 68th Armor Regiment left Fort Irwin with three of 29 tanks operational and zero of 18 Bradely fighting vehicles operational. It was late November and 3rd Armored Brigade Combat Team (ABCT) was scheduled to begin outload operations in January. In six working weeks, the battalion rebuilt the operational readiness (OR) rate to 79 percent and drove 37 of 47 combat platforms (under their own power) from the motor pool to the railhead.

During the subsequent deployment to the U.S. European Command area of operations, the battalion maintained a readiness rate of 77 percent or better throughout the deployment. This statistic includes 30 days of Field Operations. This was despite a national (federal) budget funding deficit for the first quarter and being at the end of the supply line as a standalone battalion. After National Training Center Rotation 24-02 the battalion maintenance program needed some additional rigor. That rigor came in the form of a meeting observed in the adjacent aviation brigade: The production control meeting (PCM) and the plan methodology (problem, people, parts, time, tools, and training or P4T3).

Production control, ABCT maintenance

Maintenance is important in any formation, but it is especially vital in both aviation and armor units. For years, Army aviators have adhered to the P4T3 methodology to ensure their equipment is maintained to the highest standard. Prior to NTC, the concept of executing a PCM had been discussed inside the battalion. However, many ground units are reluctant to adopt the PCM, as it seems cumbersome and impossible to accomplish. One issue that arose is the difference between the amount of support personnel assigned to aviation units compared to those assigned to an armored unit. For example, assets available at the aviation squadron/battalion level differs from a those of a combined arms battalion (CAB). If you ever sit in an aviation PCM, you’ll be surrounded by chief warrant officers, military occupational specialty (MOS) 92Y, Unit Supply Specialists; and field service representative (FSR) liaisons. On the other hand, a CAB has one maintenance warrant officer and limited habitual direct support from FSRs. And that’s okay. The PCM and P4T3 is still a framework that CABs can use to prioritize the assets you do have.

The PCM developed over time, after attending a few aviation PCM’s with the 6th Squadron, 17th Air Cavalry Regiment and using Army Techniques Publication (ATP) 3-04.7, Army Aviation Maintenance as a guide. The 1-68 Armor trained company executive officers (XOs) to brief status on equipment using the P4T3 model. Briefers were trained to cut to the point quicker by describing the P4T3 challenges directly as opposed to briefing all seven steps individually.

There was a lot of maintenance to be done, with limited crews and mechanics to do it all. Over time, the PCM allowed a daily touch point for commander priorities, that provided troops to tasks, and job prioritization that previously had been overwhelming. The focus enabled field maintenance teams (FMTs) and the maintenance platoon to apply themselves to directed maintenance priorities based on parts, people, and tools available. The PCM also armed the battalion leadership with accurate projections for daily maintenance expectations.

The PCM is now executed four days a week (Tuesday-Friday). This 30-minute or less meeting produces daily maintenance priorities and troops to tasks. This is now the most important meeting in the battalion and ensures the fleet receives the appropriate attention necessary. Executing a PCM 30 minutes prior to the duty day, commanders (CDR) or XOs brief planned jobs. Support shops/sections back-brief planned jobs to confirm priority. This immediate feedback and direct coordination lead to an increase in OR rate, decreasing time equipment spent non-mission capable by roughly 30 percent across the battalion. The ability to address any of the seven areas in that meeting and alleviate issues allowed for a shared understanding and “ownership” of who would remedy the gaps in assets or support. This reduced the “3-foot wall” and helps operators and mechanics understand most issues could be resolved the same day. Overall, there is a better understanding in troubleshooting and maintenance actions directly correlating to increases in readiness.

After a few months, the PCM could be conducted in as little as 20 minutes. The XOs sought maintenance resolution through cross talk, preventing issues from becoming larger problems and/or delays. With direct involvement and enforcement from the battalion command team, the companies were able to overcome hurdles and continue towards getting equipment ready to fight. The ability to conduct a quick, precise, and worthwhile meeting also allowed for the battalion command team to brief more accurate readiness pictures to higher by ensuring all obstacles were addressed and plans were in place to repair equipment as efficiently as possible.

Production control meeting

The PCM is chaired by the battalion CDR or XO. Companies are represented by their CDR or XO and the FMT chief. The meeting is supported by the battalion maintenance tech, battalion maintenance officer, and the team leads for base maintenance, search and recovery, armament, and shop office. If the battalion has other maintenance support assets, they should also attend and follow suit with the maintenance team leads.

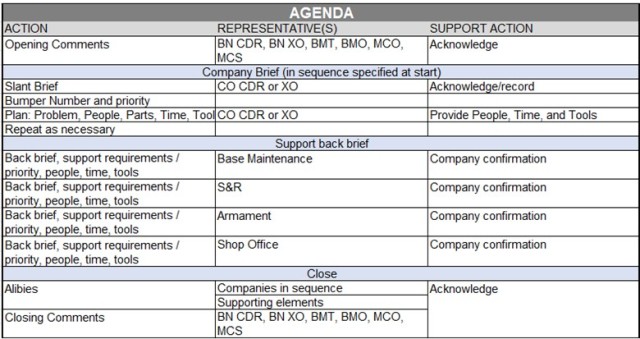

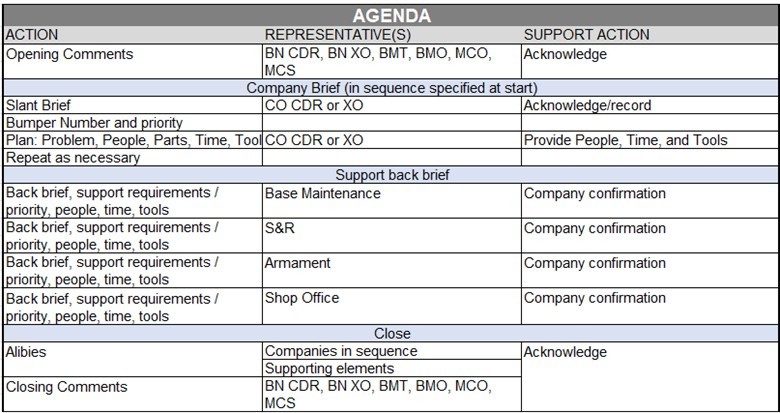

The meeting begins with opening comments from the chair, then quickly moves to the companies to brief their slant (operation readiness rate) then priority jobs by bumper number. While briefing priority jobs, the P4T3 method is used to confirm that all resources and assets are in place to complete the job. This is repeated for each of the jobs planned for that day. Expeditionary maintenance can be chaotic. Finding available special tools or a part that just came off the logistics package can derail the maintenance team for hours. This check served as confirmation the team was ready to work and complete the job. After each of the companies completes its brief, the support elements back brief the priorities and confirm for shared understanding. This critical step that was previously missed in battalion maintenance meetings, since support elements were generally there in a more passive receive role. The PCM gives them an active role and forces communication between line companies and the battalion support sections. Figure 1 below is the agenda and meeting framework for the PCM.

Figure 1. Agenda. (U.S. Army)

One of the most immediate impacts from the PCM was the dedication of battalion support elements (weld support, wheeled mechanics, light track mechanics, M88s, etc.) to the application of the meeting’s outputs. One example of tangible feedback following the implementation of the PCM is the number of weld jobs the battalion completed. Prior to NTC 24-02, the unit welder averaged one weld job a week. Previously the lack of priorities and oversight of the welder workload was a blind spot in the maintenance program. Following the introduction of the PCM the unit welder completed anywhere from 10-15 jobs a week.

Plan methodology

The plan methodology is well discussed in Army aviation. Chuck Brown’s article, “P4T3 Supporting ‘Ready Now’ Maintenance” (Flightfax, 2019)1 and resident experiences provide the maintenance team with the tools to ensure conditions were set to begin a specific job. The methodology develops the plan by identifying the problem, people, parts, time, tools, training required.

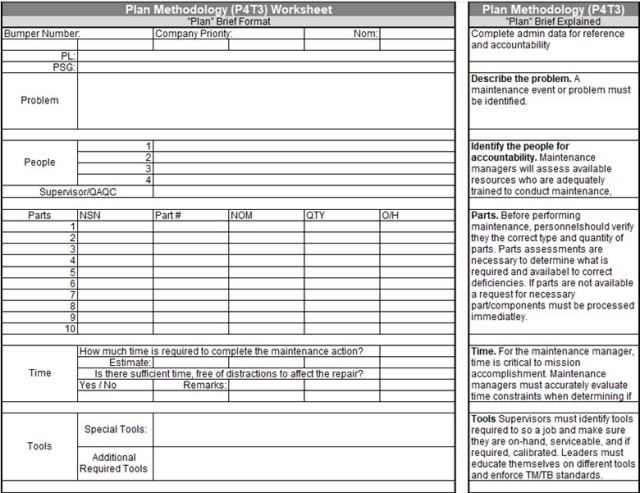

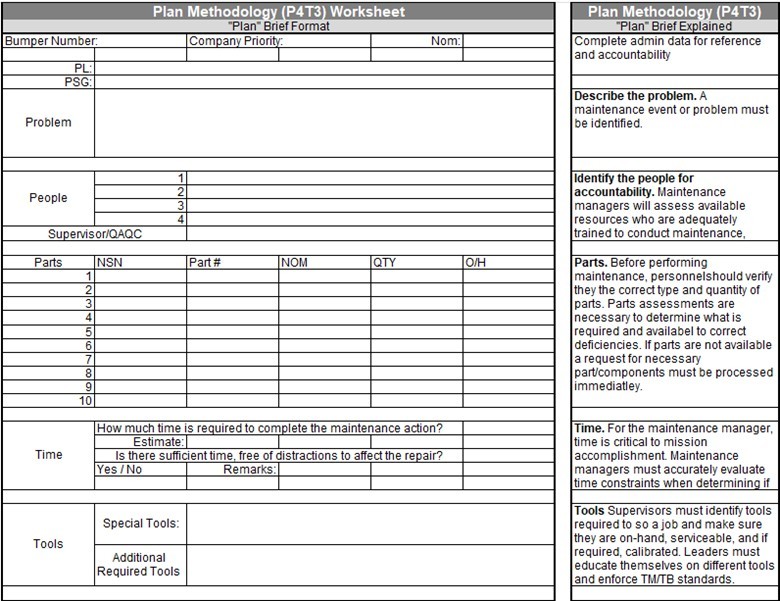

Figure 2 is a worksheet made to allow operators, mechanics, and leaders to develop their plan. Once the worksheet is completed, it can be provided from the platoon leadership to the company to prioritize jobs and brief higher headquarters. If the plan is incomplete, additional resources must be provided before the job can be started. A complete plan means the job is ready to action.

Figure 2. Plan Methodology (P4T3) Worksheet. (U.S. Army)

Strict adherence to the P4T3 briefing methodology is critical to keeping the meeting productive and concise. However, support elements/sections include in their back briefs an additional outline of jobs their subordinate teams are executing to ensure the whole team is used effectively. Example, Example, Team 1 is supporting an Infantry Fighting Vehicle with an M88 Recovery Track, Team 2 is processing recoverable parts for turn in, and Team 3 is conducting annual services on two Light Track Vehicles. This shows us that Team 2 could be used more effectively on another job. This additional step helps drill down to the individual Soldier for troops to tasks and efficiency. Recommend adding that in as an additional step. Keep the companies to the P4T3 style briefing and shared sections brief P4T3 based on teams available.

Conclusion

The production control meeting is not exclusive to aviation formations. The PCM is widely applicable and can be used at the battalion and company levels to help organizations prioritize and manage maintenance programs. There is only one way to eat an elephant: one bite at a time. For the 1-68 Armor, the PCM allowed company FMTs to take small bites out of a major maintenance problem, and it established a means to manage jobs in a fast-paced ABCT operations tempo. The P4T3 methodology provided a framework to brief maintenance priorities and confirm conditions are set prior to each duty day. Implementing these practices across the battalion enabled positive organizational change in maintenance and readiness.

LTC Michael D. Hebert is the battalion commander of 1st Battalion, 68th Armor Regiment, 3rd Armored Brigade Combat Team, 4th Infantry Division, Fort Carson, CO (both at Fort Carson and Forward Operating Site, Nowa Deba Training Area, Poland). LTC Hebert’s previous assignments include aide de camp to the commanding general of Installation Management Command, Fort Sam Houston, TX; brigade XO, 3rdABCT, 1st Cavalry Division, Fort Cavazos, TX; squadron XO, 6th Squadron, 9th U.S. Cavalry Regiment, 3rd ABCT, 1st Cavalry Division, Camp Casey, Republic of Korea; and squadron operations officer; 6-9 Cavalry, 3rd ABCT, 1st Cavalry Division, Fort Cavazos. His military schools include U.S. Army Ranger Course, U.S. Army Airborne Course, Cavalry Leader Course and the Scout Leader Course, all at Fort Moore, GA. LTC Hebert has a bachelor’s of arts degree in communications from Louisiana State University and a master’s of arts degree in National Security and Strategic Studies from the Naval War College.

MAJ Grant P. Roberts is the battalion operations officer, 1-68 Armor, 3rd ABCT, 4th Infantry Division, Fort Carson, CO. His previous assignments include battalion XO, 1-68 Armor, 3rd ABCT, 4thInfantry Division; aide-de-camp, to the Supreme Allied Commander Europe / Commanding General, U.S. European Command, North Atlantic Treaty Organization (NATO) Headquarters, Belgium; company commander, Headquarters and Headquarters Company, 1stBattalion, 77th Amor Regiment, 3rd ABCT, 1st Armored Division, Fort Bliss, TX; and mechanized infantry company commander, 1st Battalion, 77th Amor Regiment, 3rd ABCT. MAJ Roberts’ military schools include U.S. Marine Corps Command and Staff College, Quantico, VA (2023); Joint Fire Power Course, Nellis Air Force Base (AFB), NV (2018); Bradley Commander Course, Fort Moore, GA (2017); Maneuver Captain’s Career Course, Fort Moore (2017); Basic Airborne School, Fort Moore (2014); Ranger School, Fort Moore (2014); and Infantry Basic Officer Leader Course, Fort Moore (2013). He has a bachelor’s of arts degree in political science from Miami University (2010). MAJ Roberts also has a master’s of arts degree in communications from Bellarmine University (2013) and a master’s of science degree in military studies from the Marine Corps University (2023). MAJ Roberts’ awards and decorations include the Meritorious Service Medal, Joint Service Commendation Medal, Army Commendation Medal (3 oak leaf clusters), Army Achievement Medal, Meritorious Unit Citation, National Defense Service Medal, Afghanistan Campaign Medal, Global War on Terrorism Medal, Korean Defense Service Medal, Army Service Ribbon, Overseas Service Ribbon, NATO Defense Medal, Combat Infantry badge, Expert Infantry Badge, Parachute Badge, Order of Saint Maurice (Centurion), German Armed Forces Proficiency Badge (Gold), German Airborne Wings (Bronze).

CW4 Wes Leach is a U.S. Army chief warrant ordinance officer currently serving as the battalion maintenance tech, 1-68 Armor, 3rd ABCT, 4th Infantry Division, Fort Carson, CO. His previous assignments include automotive warrant officer, 1-68 Armor; senior ordnance ground maintenance warrant officer, 1-2 Stryker Brigade Combat Team (SBCT); automotive warrant officer, 23rd Brigade Engineer Battalion, 1-2 SBCT; automotive warrant officer, 3rd Battalion, 13th Field Artillery Regiment; and automotive warrant officer, 709th Military Police Battalion. CW3 Leach’s military schools include Intermediate Level Education (formal education program for mid-career U.S. Army officers. It's a required part of the Command and General Staff Officer Course), Fort Rucker AL; Warrant Officer Advanced Course, Fort Gregg-Adams, VA. He has a bachelor’s of science degree from Embry Riddle Aeronautical University.

CPT Colleen Talbott is the battalion maintenance officer, 1-68 Armor, 3rd ABCT, 4th Infantry Division. Fort Carson, CO. Her previous assignments include XO, 1st Battalion, 81st Armor Regiment; XO, 1st Battalion, 35th Armored Regiment; and tank platoon leader, 1-35 Armor. Her military schools include Armor Basic Officer Leader Course, Fort Moore, GA; Army Reconnaissance Course, Fort Moore; Maneuver Captain’s Career Course, Fort Moore; and Tank Commander Course, Fort Moore. CPT Talbott has a bachelor’s of science degree in biology from Radford University and master of social work degree in social work from Troy University.

Notes

1 Chuck Brown, “P4T3 Supporting ‘Ready Now’ Maintenance” (Flightfax, 2019) https://safety.army.mil/Portals/0/Documents/ON-DUTY/AVIATION/FLIGHTFAX/Standard/2019/Flightfax_78_June_2019.pdf.

Acronym Quick-Scan

ABCT – armored brigade combat team

CAB – combined arms battalion

CDR – commander

FMT – field maintenance team

FSR – field service representative

P4T3 – problem, people, parts, time, tools, and training

PCM – production control meeting

NTC – National Training Center

XO – executive officer

Social Sharing