In early 2012, the drawdown of personnel, materiel, and base infrastructure throughout the Combined Joint Operations Area-Afghanistan was in its infancy. The need for a structured, organized, systematic, and methodical retrograde process quickly became apparent. The U.S. Central Command (CENTCOM) materiel retrograde element (CMRE) concept was established by leaders and embraced as the way forward to the drawdown in Afghanistan.

THE CMRE SOLUTION

The first CMRE stood up in April 2012 and was initially made up of Soldiers from the 427th Brigade Support Battalion, which was deployed to Bagram and Kandahar Airfields in Afghanistan and task organized under the 10th and 45th Sustainment Brigades.

On June 18, 2012, the 18th Combat Sustainment Support Battalion (CSSB) from Grafenwoehr, Germany, came into theater to provide mission command of all CMRE enablers. The 593rd Sustainment Brigade, commanded by Col. Douglas M. McBride, assumed the brigade mission in August 2012.

The CMRE solution for retrograde in Afghanistan consists of enabler teams dedicated to assisting with "reposturing" the theater. The CMRE missions included using various retrograde teams to execute recovery, redistribution, retrograde, reset, disposal of excess materiel, and base closure and transfer assistance. Initially, the teams were reactive, assisting task forces with base closures or transfers if they were in danger of missing their proposed closure or transfer dates.

The 593rd Sustainment Brigade identified the requirement for a forward retrograde element (FRE) as the solution to synchronizing theaterwide retrograde plans while maintaining the flexibility to tailor operations to local task force mission parameters. This concept allowed the CMREs to change from a reactive posture to a proactive posture.

THE INITIAL CONCEPT

Base closure assistance teams (BCATs) focused on helping units to identify foreign excess personal property (FEPP) and foreign excess real property (FERP). FEPP is equipment or items such as air conditioners, t-walls, and office equipment that the owning unit determines is excess and can be transferred to the Afghan government. FERP follows the same definition but is for structures that are not moveable, such as concrete buildings.

Since the unit tasked with the physical retrograde plan was usually determined before the BCATs were requested, paperwork became critical for a successful closure or transfer. The main reason the BCATs were requested so late was because of the lack of theaterwide knowledge of CMRE capabilities. In August 2012, the BCATs deployed earlier in the closure process and started their assessments with a reconnaissance conducted 180 days before closure or transfer.

A base closure or transfer served as the decisive operation for the CMREs. Other enablers, such as mobile redistribution teams or mobile container assistance teams, handled shaping and sustaining operations, including improving the overall retrograde process. Those improvements started at the tactical infrastructures and ended at the strategic bases with the retrograde sort yards.

As the teams and concepts matured, the 18th CSSB support operations officer developed a plan to push the CMREs out from the strategic bases and embed them at operating bases with the local task force headquarters and brigade support battalions. At this point, the CMRE companies were task organized as FREs. This task organization allowed CMRE teams to anticipate and synchronize retrograde and drawdown from planning through execution at the task force level.

FRE TASK ORGANIZATION

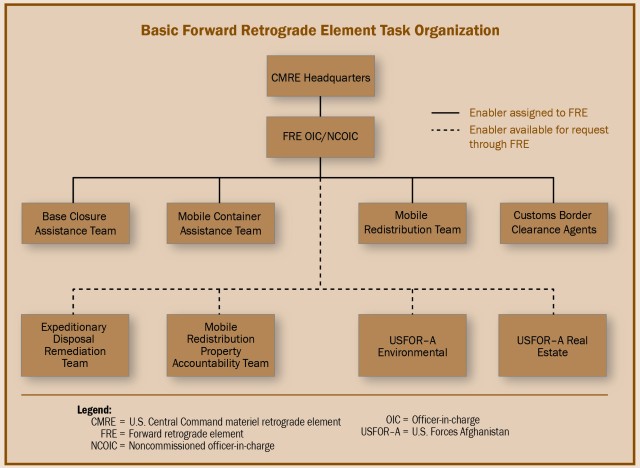

The FRE consists of a mission command element, a BCAT, a mobile redistribution team (MRT), customs border and certification agents, and a mobile container subject matter expert. The mission command element consists of an officer and senior noncommissioned officer (NCO). (See figure 1.)

The officer-in-charge (OIC) allows the FRE to assist with and provide subject matter expertise for the overall retrograde plans of the brigade engineer, brigade S-4, and support operations officer-in-charge. The senior NCO primarily focuses on daily execution of FRE operations. The mission command section acts as the project management cell and ensures that drawdown timelines are maintained and CMRE teams are properly coordinated.

The base closure section consists of six contractors focused on assisting task forces and forward operating base mayors with Afghanistan base closure and transfer requirements. These include identifying FEPP, FERP, real estate, environmental, contracting, document processing, and Logistics Civil Augmentation Program (LOGCAP) contract requirements.

The MRT consists of two NCOs and 10 contractors. The main duty of the MRT is to operate an expeditionary retrograde sort yard at an operating base to sort excess equipment before shipping it to the strategic base retrograde sort yards. The MRTs maintain the flexibility to push forward to tactical infrastructure locations to conduct short-term sorting operations.

The customs section of the FRE consists of at least two junior enlisted Soldiers. These Soldiers spend most of their time assisting the redistribution property accountability team yards and ensuring that major end items are properly inspected and customs-cleared before being retrograded. The customs section also has the flexibility to assist local units by conducting customs inspections of their organic equipment and personnel before redeployment.

Lastly, the container management subject matter expert, a junior enlisted Soldier, is responsible for ensuring that container management is maintained throughout the retrograde process. This includes ensuring that the task force assigns container control officers who are responsible for maintaining container accountability throughout the task force area of operations. The container management subject matter expert audits the Integrated Booking System-Container Management Module for accuracy and monitors the movement of containers during retrograde.

The container management specialist also assists redeploying units by certifying that containers are seaworthy. Future versions of the FRE task organization could benefit from the addition of a movement control team, a mobile redistribution property accountability team (MRPAT), and an organic expeditionary disposal remediation team (EDRT). EDRTs are currently stationed at strategic bases and pushed out to operational and tactical units when requested.

IMPROVEMENTS TO OPERATIONS

The FRE assists with the drawdown and retrograde from its start at the closing location through the completion of retrograde, redistribution, or disposal. From April to August 2012, the BCATs conducted assessments, ensuring that paperwork was up to date and the task force had a plan to remove excess equipment.

This methodology was an effective short-term solution for closures or transfers. But over time, this caused excess materiel to accumulate at the operating bases and other strategic hubs, resulting in the retrograde process essentially starting anew.

It was also difficult to synchronize operations between the brigade engineer and supply sections. This caused base closure teams to work mainly with the engineers, leaving the S-4 out of the retrograde loop. With the FRE's involvement from start to finish and its optimized location at the operational bases, retrograde items could continuously flow to the retrograde sort yards at the strategic bases.

The FRE's involvement in retrograde starts with an initial assessment by the BCATs. The closure team starts the required paperwork, identifies FEPP, FERP, and LOGCAP requirements, and uses lessons learned from previous assessments to advise the unit of any potential friction points.

During this assessment, the container management specialist identifies excess containers and conducts an audit of Integrated Booking System accuracy. When the closure team returns from the assessment, the FRE OIC arranges any follow-on enabler support, including environmental, EDRT (for excess scrap metal), MRPAT (for excess major end items), and engineer support. The FRE OIC also assists the brigade support battalion support operations officer in ensuring that enough transportation assets are available and the convoy timelines are in line with the closure timeline.

As equipment is retrograded, the container management specialist tracks any containers, ensuring they are out-gated and in-gated at each leg of their trip. The container specialist works with the local container control officers to ensure that container visibility is maintained throughout the process. Maintaining container visibility allows the MRT and strategic retrograde sort yards to prepare and plan for any influx of excess equipment.

When the containers arrive at the expeditionary retrograde sort yard at the operating bases, the MRT opens the containers and sorts the equipment. Conducting sorting operations at the operational bases has many benefits. This midprocess step facilitates efficient use of transportation, ensures property and equipment are shipped to the right locations, and ensures trash is disposed of locally.

The expeditionary retrograde sort yard allows the task force to hold units accountable for sending trash, hazardous materials, and dangerous contents in containers. At first, the goal was to push the MRTs out to the forward operating bases and retrograde the excess equipment directly to strategic bases. However, because of the highly kinetic environment at these locations and the requirement at many bases to use sling load to transport equipment, it became apparent that the best location for the MRTs is at the operational bases with the FREs.

A permanent, more stationary location to conduct sorting operations for MRTs is best for efficient and effective retrograde operations. The required supplies, such as shipping boxes, and the real estate required for storage and materials-handling equipment can be easily resourced. Many of these essential items are not available at forward locations.

Unit accountability is not easily enforced when containers are shipped directly to the strategic retrograde sort yards. Although not ideal in times of heavy retrograde, the containers can bypass the operational base sort yard and go directly to the strategic base retrograde sort yard for processing. After the excess containers are sorted, the equipment is either sent to the Defense Logistics Agency Disposition Services, retrograded back to the United States, or redistributed within Afghanistan to units that are in need of the equipment.

Over the past year, the evolution of the CMRE and FRE concept has made dramatic progress and continues to change in this dynamic combat environment. The initial mission command challenges allowed for opportunities to maximize leadership within decentralized organization. As the FRE matures, more enablers will embed into operations to specifically tailor the FRE to meet the local task force's requirements and timelines.

The FRE provides seamless retrograde operations for task forces that are otherwise focused on combat and sustainment operations. The FRE also provides a solid knowledge base, networking, and continuity for sustaining and maintaining retrograde momentum when units redeploy and are replaced. Ensuring continuous operations significantly increases the effectiveness of the overall retrograde mission throughout Afghanistan.

________________________________________________________________________________________________

1st Lt. Ryan Dennison is the executive officer of Headquarters and Headquarters Company, 427th Brigade Support Battalion, 27th Infantry Brigade Combat Team, in Syracuse, New York. He holds a bachelor's degree in mechanical engineering from Rochester Institute of Technology and is a graduate of the Transportation Basic Officer Leader Course.

________________________________________________________________________________________________

This article was published in the July-September 2013 issue of Army Sustainment magazine.

Related Links:

Army Sustainment Magazine Archives

Social Sharing