REDSTONE ARSENAL, Ala. -- A team at the U.S. Army Research, Development and Engineering Center, Aviation and Missile, has recently worked to develop a new dual pulse rocket motor.

The Weapons Development and Integration Directorate has worked under the endorsement of the Counter Rocket Artillery Mortar Product Office and the Cruise Missile Defense Systems Project Office to demonstrate a low cost, dual pulse rocket motor incorporating insensitive munitions capabilities.

The program was funded by the Joint Insensitive Munitions Technology Program.

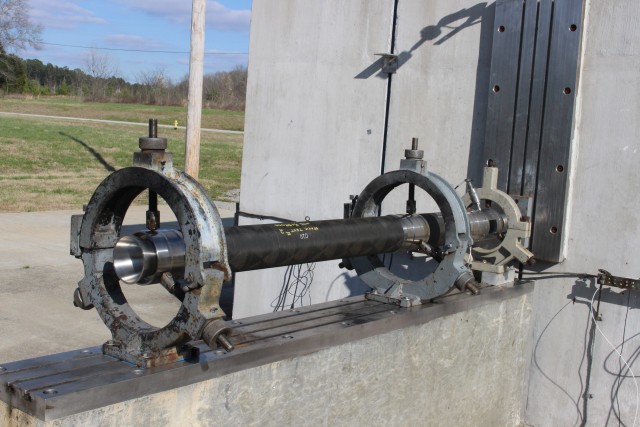

The team at WDI had a goal to ultimately explore technologies in rocket motor propulsion to help lead to a low-cost, dual pulse rocket motor. A dual pulse rocket motor contains propellant that is divided into multiple sections by an internal barrier, which will perforate as the second igniter fires to allow the propellant to exhaust through the same nozzle as the first propellant.

The project was born in FY13 out of a program known as the Accelerated Improved Interceptor Initiative, or AI3 Interceptor, as a potential upgrade to the baseline rocket motor. The AI3 Interceptor program was halted, causing the JIMTP funded team to change their focus and downscale. Because the team was successfully demonstrating insensitive munitions technologies that hadn't been demonstrated before, the program was encouraged to continue.

"We've facilitated some other programs to be stood up that are following a similar motor case and propellant configuration," said Nathan Mathis, a chemist with WDI's Energetic Materials function.

Mathis and his team were able to use knowledge they gained from the JIMTP propulsion program to successfully transition into developing the dual pulse rocket motor. The team was given direction for the program through the C-RAM product office, with CMDS providing insight, as well. The two organizations gave the team general length constraints to design within.

The rocket motor had to meet insensitive munitions requirements. Insensitive munitions testing is a set of hazards assessment testing for munitions.

Six tests will potentially exploit vulnerabilities in a munition: testing for bullet impact, fragment impact, slow cook off, fast cook off, sympathetic reaction and shaped charge jet impact.

Scores for these tests are labeled as Type reactions and range from Type I -- Type VI. Each one measures a different level of reaction, ranging from a detonation reaction being Type I, to no reaction being a Type VI.

Because the JIMTP is developmental, the scores given to this rocket motor were unofficial. "Through a significant amount of design work and subscale testing, our final design culminated in Type IV reactions in fragment impact, slow cook off, and fast cook off testing. Due to program funding limitations we did not conduct the other three insensitive munitions tests. So, the Type IV reactions were great results, especially in fragment impact," Mathis said.

The team scored a Type IV, but because the insensitive munitions test is a systems level test there may be certain mitigations that will help the Type IV become a Type V score. Official insensitive munitions testing is focused on the final system and the manner in which it is deployed.

For a missile, this would go beyond the rocket motor to include all of the other missile components.

"I feel that we have gained significant understanding through the JIMTP effort and that we can lay out path in a missile configuration that can take some of our Type IV reactions and improve them to Type V reactions," said Mathis.

Insensitive munitions safety testing for the rocket motor design was performed at NTS in Camden, Ark., and at Redstone Test Center on Redstone Arsenal. All of the traditional motor firings were done within WDI. Final testing was completed early March.

This is the first dual pulse rocket motor that has been developed in house at AMRDEC. "Hands-on missile technology development and demonstration is a critically important and rewarding opportunity for the WDI/AMRDEC workforce," said Christi Dolbeer, deputy director of WDI. "The successful design, fabrication, and testing of the first in-house dual pulse rocket motor is a prime example of strengthening AMRDEC's capabilities while solving technical challenges for our customers."

---

U.S. Army Aviation and Missile Research, Development and Engineering Center is part of the U.S. Army Research, Development and Engineering Command, which has the mission to provide innovative research, development and engineering to produce capabilities that provide decisive overmatch to the Army against the complexities of the current and future operating environments in support of the joint warfighter and the nation. RDECOM is a major subordinate command of the U.S. Army Materiel Command.

Social Sharing