From mounting platoons on motorcycles in the 1970s, to the infamous "fast food" T-rations of the '80s, to heavy equipment transporters and desert mobility vehicle systems of the '90s, rapid and enduring advances in technology continue to propel sustainment operations to meet the requirements of an expeditionary force.

But this progress often leaves junior Soldiers on the battlefield wondering, "Who was the good idea fairy that decided to upgrade my system?" and senior leaders questioning, "Who supported the decision to field this equipment?"

Other questions include, "Who is the trusted agent that provides an objective eye to innovative military systems?" and most importantly, "Who implements and protects the Soldier's perspective in this process?" The answer to all of these questions is the Army Operational Test Command (OTC), which is headquartered at Fort Hood, Texas.

The OTC's mission is to conduct independent operational testing that promotes acquisition and fielding decisions while placing Soldiers' perspectives at the forefront of modernization. OTC is composed of eight directorates that test the entire gamut of new equipment. One is the Maneuver Support and Sustainment Test Directorate, which is divided into two divisions: Maneuver Support and Sustainment.

These divisions conduct independent operational testing in support of the Engineer, Chemical, Military Police, Quartermaster, Transportation, and Ordnance Schools. Contributions of the Sustainment Division have played a notable role in shaping the armed forces.

The Army has a growing need to ensure that all fielded systems and new systems being developed are designed to work together as a larger family of systems. As the independent test agency for designated multiservice and joint systems, the OTC is entrusted to ensure systems are effective and suitable for use in combat by typical military users.

OPERATIONAL TEST TYPES

"Operational test" is a generic term that encompasses a wide range of testing and experimentation conducted in realistic operational environments with users who are representative of those expected to operate, maintain, and support the system when fielded.

Army Regulation 73-1, Test and Evaluation Policy, categorized tests as early user tests, early user experiments, limited user tests, initial operational tests, or follow-on operational tests.

EARLY USER TEST. An early user test employs representative users during the technology demonstration phase of the acquisition process. It is normally performed on prototypes to gain an understanding of the materiel concept, support planning for training and logistics, identify interoperability problems, and identify future testing requirements.

EARLY USER EXPERIMENT. An early user experiment is conducted to identify potential system-related solutions and to define issues further addressed within the acquisition process.

LIMITED USER TEST. A limited user test addresses a small number of issues identified during the acquisition process and can be conducted anytime during the acquisition phase.

INITIAL OPERATIONAL TEST. An initial operational test serves as the system's "final exam," in which data is presented on operational effectiveness, suitability, and survivability of a system when operated by typical users under realistic conditions.

FOLLOW-ON OPERATIONAL TEST. A follow-on operational test may be necessary during or after production to refine estimates made during initial testing. This test may also provide data to ensure that the system continues to meet operational needs and retains its effectiveness in a new environment or against a new threat.

THE TSARC

After choosing the relevant test type, Soldiers, equipment, and other resources are gathered. The test schedule and review committee (TSARC) is the method used to obtain Soldiers and other resources for operational tests. The TSARC is a process to centralize the management of resources for operational tests, force development, or experimentation.

A committee of senior leaders maximizes limited resources while minimizing the impact on unit operational readiness. The TSARC, as a decision-making body, sets operational test priorities, coordinates troop support, and reviews schedules and resources.

If your unit is chosen to support an operational test, depending on your perspective, you can either blame or thank the TSARC.

TACTICAL WHEELED VEHICLE TESTS

Since 2005, the Maneuver Support and Sustainment Test Directorate has conducted operational tests on almost every type of tactical truck in the inventory, primarily in response to urgent need statements for add-on armor. Sustainment system tests included the heavy equipment transporter (HET), family of medium tactical vehicles (FMTV), heavy expanded-mobility tactical truck (HEMTT), heavy dump truck, and the M915A5 line-haul tractor truck, which were all undergoing redesign to accommodate additional armor.

HETs, including the M1070A1 tractor and its associated M1000 semitrailer, can transport a 140,000-pound M1 Abrams main battle tank. The purpose of the HET operational test was to confirm that the M1070A1 tractor design improvements did not hinder its operational effectiveness and suitability.

FMTV is a group of wheeled vehicles built with a common truck cab, engine, drive train, and suspension. The purpose of the FMTV operational test was to assist in assessing whether selected variants of FMTV vehicles produced by a particular vendor are effective and suitable when operated by Soldiers under operational conditions. The overall test program supported qualification and verified that the vendor met existing requirements using primarily an existing design.

The M915A5 answers an urgent need to replace an aged truck tractor line-haul fleet and provide armor protection to occupants. A follow-on operational test was conducted to verify the M915A5 design and its planned field support for system type classification and materiel release requirements.

MRAP VEHICLE TEST

Most Soldiers recognize mine-resistant ambush-protected (MRAP) vehicles, notable for their V-shaped hull and armor protection. They have been providing security for expeditionary units since 2008 in Iraq. The initial fielding of the MRAPs provided a fast solution that increased survivability and mobility of forces operating in hazardous fire areas and combat zones laden with improvised explosive devices.

MRAP variants tested in conjunction with other MRAP vehicles included the MaxxPro Dash, the Cougar category II ambulance, the MRAP all-terrain vehicle, and the MaxxPro recovery vehicle. A test of the MRAP MaxxPro long wheelbase ambulance will take place in May 2015 at Yuma Test Center at Yuma Proving Ground, Arizona.

CAMEL II INCREMENT ONE TEST

The purpose of the integrated developmental and operational limited user test for the unit water pod system Camel II increment 1 was to evaluate the system's capabilities in a realistic operational environment when operated by military occupational specialty (MOS) 92W (water treatment specialist) Soldiers.

The test assessed the Camel II's ability to provide a maneuver unit with a one-day supply of potable water while allowing for a maximum loss of 10 percent.

HUMAN REMAINS TRANSPORT AND DECONTAMINATION

The chemically contaminated human remains transport and decontamination system consists of two subsystems: the contaminated human remains pouch A and the mortuary affairs contaminated remains mitigation site set.

Pouch A is a chemically contaminated human remains transport system comprising two permanently sealed internal protective pouches nestled inside an external transport case.

The mortuary affairs contaminated remains mitigation site set is a decontamination kit consisting of tentage, plumbing, heaters, rollers, sensors, medical equipment, and other items necessary to establish a nonambulatory decontamination site to decontaminate and package human remains for transport to the continental United States.

The purpose of this operational test was to identify the systems' capabilities and limitations with Soldiers operating the system in a realistic operational environment in support of the Department of the Army G-3/5/7 direct requirement.

MODULAR FUEL SYSTEM

Sustainment battalions in the future will benefit from a modular fuel system that will enable Soldiers who support mechanics and equipment from a distribution platoon to act as a resupply unit. As a force multiplier, the modular fuel system will allow Soldiers to rapidly establish a fuel distribution and storage capability at any location, regardless of the availability of construction or materials-handling equipment. Test players will include MOS 92F (petroleum supply specialist) and 91J (quartermaster and chemical equipment repairer) Soldiers.

BATTLEFIELD KITCHEN

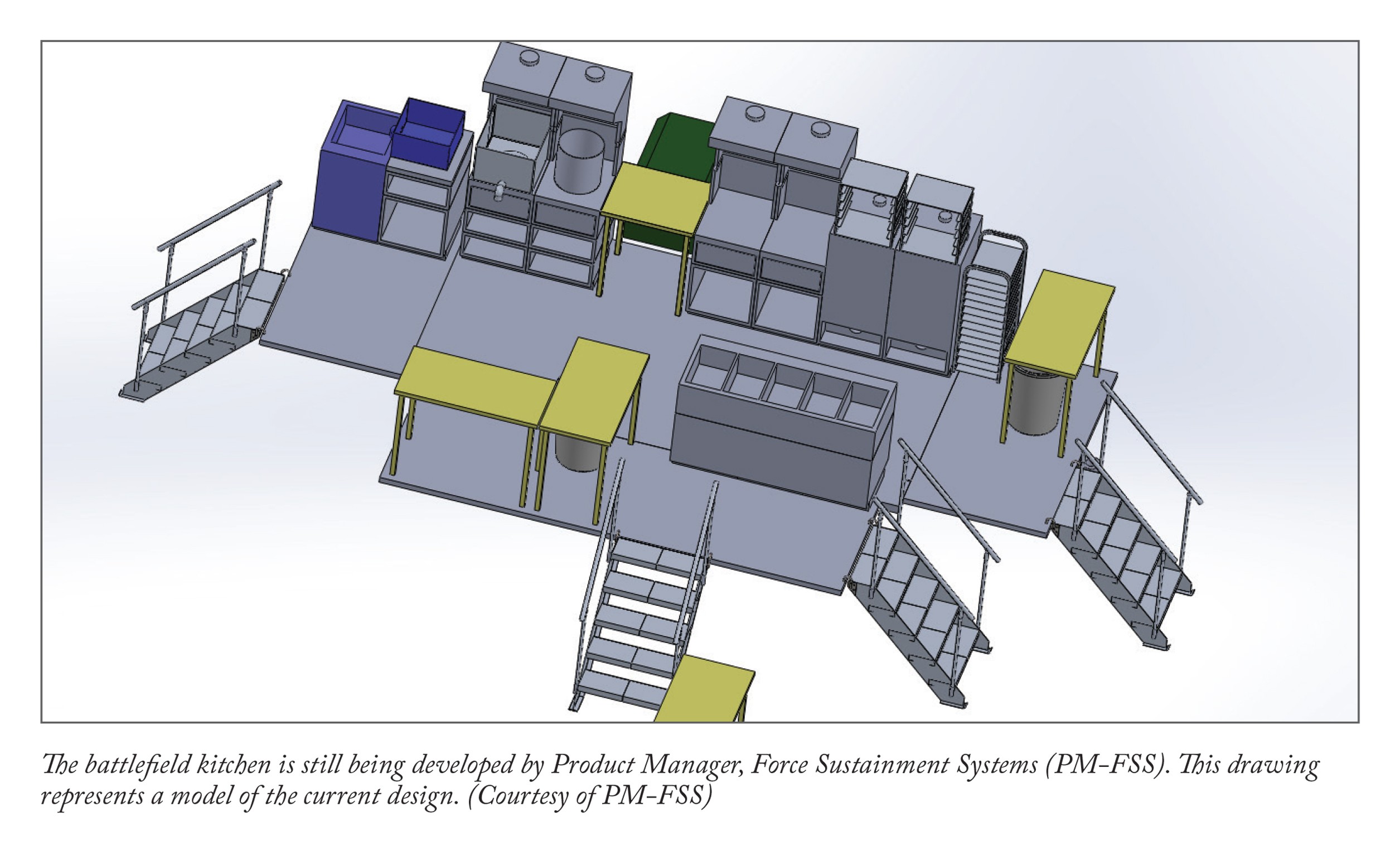

Future tests include the battlefield kitchen, which is intended to replace the aging mobile kitchen trailer on a one-for-one basis. It will provide a full-service field kitchen capability for echelons-above-brigade units, replacing the legacy mobile kitchen trailers.

The operational outcome is to provide echelons-above-brigade field feeding teams with a new kitchen that includes energy-efficient, modular, closed-combustion appliances and lower cost burners with thermostatic control to reduce fuel consumption. Compared to current kitchen systems, the battlefield kitchen will have the lowest operations and maintenance cost over the life of the program because of low fuel requirements and onboard mechanical refrigeration.

JLTV TESTING

A recent 2014 test of the joint light tactical vehicle (JLTV) at Fort Stewart, Georgia, included 10 prototypes from three different vendors. Test players included Soldiers and Marines who maneuvered each vehicle through a gamut of operational scenarios across 1,200 miles. The JLTV will protect mobility for joint forces requiring a range of capabilities beyond those of current up-armored humvees.

According to the capability development document, the overall purpose of the JLTV is to restore joint forces' light tactical mobility, payload, and performance by providing protection, transportability, mobility, sustainment, and networking. The JLTV initial operating test is scheduled for 2017.

CONSTRUCTION EQUIPMENT TRAILER

The operational evaluation of the M870A4 40-ton low-bed semitrailer will consist of a user excursion conducted at Aberdeen Test Center, Maryland. A user excursion was selected because of the single operational task required of a trailer (transporting mission-essential equipment) and the large number of overlapping tasks between developmental testing and operational testing.

The semitrailer low-bed construction equipment trailer directly supports the Military Support to Stabilization, Security, Transition, and Reconstruction Operations Joint Operating Concept that is aligned with military campaigns in pursuit of national strategic objectives in the 2014 to 2026 time frame.

TEST PROFESSIONALS

Teams are composed of a test officer, an operations research systems analyst (ORSA), and a research, development, test, and evaluation (RDTE) noncommissioned officer (NCO).

TEST OFFICER. Test officers assigned to the Sustainment Division are charged with planning, resourcing, executing, and reporting on operational tests of wheeled vehicles and ordnance, quartermaster, and other support systems.

A good test officer renders sound acquisition and military expertise in the operational test design, planning, execution, and reporting for systems under testing. Led by the test officer, tests and evaluations occur worldwide, sometimes in remote areas.

Detailed knowledge of test systems is gained through extensive technical and doctrinal research. The test officer must have good oral and written communication skills in order to articulate test designs to senior military and Department of Defense civilian leaders.

ORSA. The ORSA is a critical test team member who provides expertise in producing statistical products to convey test requirements and provides developmental input to system and event planning and reporting. ORSAs assist in developing additional plans and reports, such as the system evaluation plan, test data report, test report, and operational evaluation report.

To further shape test requirements, a pattern of analysis is developed and surveys and questionnaires are created in conjunction with the data collection plan. The ORSA, armed with operational research techniques, statistical modeling, and other quantifiable analysis tools, develops end-to-end methods and test design plans to ensure that valid, reliable, and statistically significant test results are collected, analyzed, and reported.

RDTE NCO. The backbone and executor of the test design is the RDTE NCO. This person's responsibilities include serving as the subject matter expert for the system being tested, refining operational issues and criteria for tests, and helping prepare operational test documentation.

Additional RDTE NCO responsibilities include preparing test site operations, acquiring resources, supervising enlisted personnel, ensuring test equipment accountability, coordinating with external agencies, assisting in meeting requirements, and functioning as a unit controller during execution events to ensure player units follow scenario requirements.

The professional OTC test team, armed with the knowledge, recommendations, and expertise of operational Soldiers, works to ensure that innovative systems fill operational gaps and become force multipliers on the battlefield. Not all systems will pass the test.

OTC is a rewarding assignment for civilians and the military. This assignment provides those who receive it with an appreciation for the acquisition and fielding processes. To join OTC as an operational test officer, an ORSA, or an RDTE NCO, military members can contact their branch managers and civilians can inquire online through www.cpol.army.mil.

___________________________________________________________________________________________

Maj. Mattii S. Minor is a test officer for the Maneuver Support and Sustainment Division, Army Operational Test Command, at Fort Hood, Texas. She holds a bachelor's degree from the University of Wisconsin-Milwaukee in finance and marketing and a master's degree from Troy State University in marketing. She is a graduate of the Quartermaster Officer Basic Course, the Combined Logistics Captains Career Course, the Combined Arms and Services Staff School, and the Command and General Staff College Intermediate Level Education.

Capt. Raygan C. France is a test officer at the Operational Test Command at Fort Hood, Texas. She holds a bachelor's degree from Troy State University in resource management and an MBA from Columbia Southern University. She is a graduate of the Transportation Basic Officer Leader Course and the Combined Logistics Captains Career Course.

___________________________________________________________________________________________

This article was published in the May-June 2015 issue of Army Sustainment magazine.

Related Links:

Army Sustainment Magazine Archives

Social Sharing