The Army Logistics Innovation Agency and Department of the Army G-4 chartered the Maj. Gen. James Wright Program of the College of William and Mary's Mason School of Business to research supply chain optimization for remote locations. The intent was to garner insights from civilian organizations with the objective of improving Army sustainment for remote locations.

The study focused on sustainment in areas with minimal or no local infrastructure or supply sources in environments similar to inland central Africa and isolated Pacific islands.

Comprehensively studying current commercial supply chain innovations revealed many best practices that should be adopted by the Army. The Army can better support combat operations in the most remote areas on earth by accomplishing these six improvements:

• Reduce packaging waste.

• Increase use of local and renewable resources.

• Employ regional logistics experts.

• Increase the prevalence of commonality of parts.

• Improve logistics communications systems.

• Generate operational power efficiently.

The research revealed how all six recommendations would lead to an increase in combat power. Combat power would be generated through a smaller footprint, greater use of assets, reduced inventory, simplified logistics, and increased operational flexibility. All six recommendations have been proven to reduce costs for commercial companies.

REDUCED PACKAGING

The Army can learn from initiatives in the private sector to reduce packaging waste. Walmart has decided that the punt (or dimple dent) at the bottom of a bottle of wine is wasteful. Walmart worked closely with its supplier to redesign the Oak Leaf brand wine bottles to reduce that punt, resulting in a shorter and lighter bottle.

This small change reaped big cost savings in glass consumption, packaging materials, and transportation, which created a win-win scenario for both Walmart and its supplier1 and reduced Walmart's annual shipping requirement by 280 trucks.2

Likewise, Freeport-McMoRan, one of the top mining companies in the world, worked closely with a supplier to completely redesign its packaging for cobalt hydroxide. The new design resulted in a larger, square-shaped product bag that was more rigid. The new design fits the exact dimensions of the company's cargo trucks and has doubled the amount of material that can be shipped in one truck.

The company paid two dollars more for the rigid bag, but the new design doubled the efficiency of its transportation network. The new design also made the packing process at the mine more efficient. Freeport-McMoRan gains a competitive advantage through its supplier relationships because it views its suppliers as strategic partners.3

What can the Army learn from these initiatives to reduce packaging waste? An initiative to reduce or redesign packaging would have a significant effect on combat operations.

Inefficient packaging results in trucks being on the road unnecessarily, poor use of air delivery assets, and inefficient use of storage space. Improved packaging would decrease the exposure of vulnerable assets along the supply chain, increase air and ground asset utilization, and reduce transportation requirements.

Most of the current packaging materials used for food, water, ammunition, and repair parts become a solid waste burden during combat operations. Solid waste must be disposed of for tactical, political, and sanitary reasons in a combat zone.

In remote areas, the common method for disposing of solid waste is to burn it. Burning packaging materials can lead to future health problems for Soldiers.4 But removing unnecessary packaging materials does not go far enough. Packaging materials should be designed to burn cleanly in a power-generating incinerator.

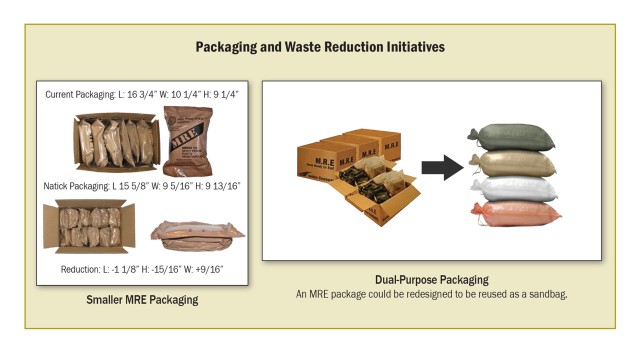

A single case of meals ready-to-eat (MREs) is a great example of poor packaging. Not only does the cardboard case create solid waste, but the individual MRE package design causes unused space within a case. (See figure 1 on page 12.) This increases the cost of packaging and printing, and it creates waste along the supply chain as these cases move on ships, vehicles, and aircraft.

Smaller and lighter packaging offers significant benefits to Soldiers who receive resupply by containerized delivery systems on air-only combat outposts. The U.S. Army Natick Soldier Systems Center has developed improved packaging for the MRE that is smaller and lighter, but it has not yet been approved by the Department of Defense (DOD).5

Natick has also considered designing dual-purpose packaging to create more value for Soldiers. For example, an MRE package could be redesigned to be used as a sandbag, a field-expedient latrine, or a camouflage net case. Soldiers should be able to use almost every piece of material the Army sends them.

The improved packaging initiative should also extend to how the Army awards contracts to suppliers who are key partners in the supply chain. Contracts should be awarded only to suppliers who comply with efficient packaging standards, to include minimum required packaging, lighter packaging, dual-purpose packaging, and clean-burning packaging.

Strict contracting requirements would no doubt put American ingenuity to work in developing smart solutions to packaging challenges. The Army must recognize that suppliers are a critical part of the value stream in the supply chain.

LOCAL AND RENEWABLE RESOURCES

Freeport-McMoRan operates mines in remote areas of Central Africa. It has adopted methods of maximizing local and renewable resources in order to reduce its logistics resupply requirement, increase its operational effect, and maximize its profits. Methods employed by Freeport-McMoRan include digging wells, partnering to refurbish a hydroelectric plant, and providing equipment and training to create local sourcing options.

Each of these methods reduces the distribution resources required to sustain operations at remote sites, freeing up assets and money to support core operations.

The Army can drastically increase combat power while reducing support requirements by using local and renewable resources. The Army would save dollars in the supply chain, and every dollar saved in logistics is another dollar that can be spent on combat power.

When Freeport-McMoRan is in a remote area, its water requirements are similar to those of an Army forward operating base (FOB) in Afghanistan. Instead of shipping bottled water to the remote site, Freeport-McMoRan constructs a freshwater well, which supplies the site and the local village with fresh water.6

The tactical benefits of building a freshwater well are fourfold: It reduces the number of resupply convoys, frees up assets for combat missions, strengthens relationships with the local community, and increases the funding available for combat power.

REDUCE RESUPPLY CONVOYS. In 2008, 20 percent of all materiel sent by convoy in Iraq and Afghanistan was related to water.7 Implementing a freshwater well to support a remote Army FOB would eliminate a significant number of resupply convoys.

FREE UP ASSETS FOR COMBAT MISSIONS. Resupply convoys operating in Iraq and Afghanistan often require Kiowa or Apache Helicopter air support. In 2007, the number of water convoys required was 3,725 (3,287 in Iraq and 438 in Afghanistan), which comes out to a little more than 10 convoys per day solely for water.8

Assuming two helicopters are required to escort one convoy, adequate air support requirements would be 20 attack helicopters per day. Reducing resupply convoy requirements by 10 or 20 percent would free up these valuable air assets for combat missions.

STRENGTHEN RELATIONSHIPS WITH THE COMMUNITY. Establishing good relationships with the local population is critical to long-term security in any operation. Building a freshwater well that supplies water to the local village as well as the Army FOB would establish an enduring relationship. Funding could be established to pay the locals for the water at far less than the cost of transporting bottled water. This would strengthen the local economy, support counterinsurgency operations, and reduce logistics support requirements.

INCREASE COMBAT POWER. Combat power is increased through a number of ways but especially through freeing up assets. Using local resources to provide water would lessen the requirement for support personnel on the FOB, which would allow for an increase in combat personnel and combat power.

Freeport-McMoRan requires essential buildings for their mines in central Africa to be made of brick. Bricks are heavy and expensive to move.

Instead of transporting bricks into Africa, Freeport-McMoRan transported the equipment required to make bricks into the remote area and trained the locals how to make them. Freeport-McMoRan then purchased the bricks from the locals.

The Army also used this method in 2007 during Operation Iraqi Freedom. Cement barriers were needed in mass quantities to cordon off areas for the Iraqi presidential election. Transporting cement barriers into Iraq was not practical, so barriers were produced locally and then procured by the Army.

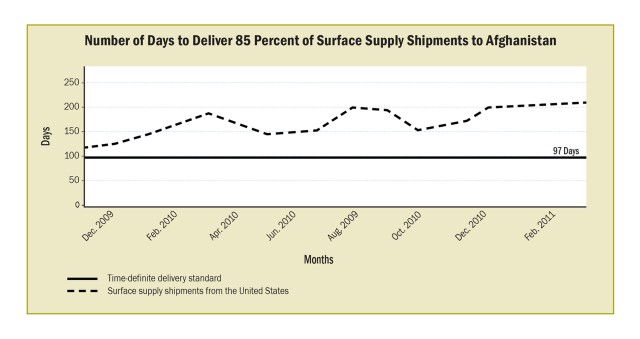

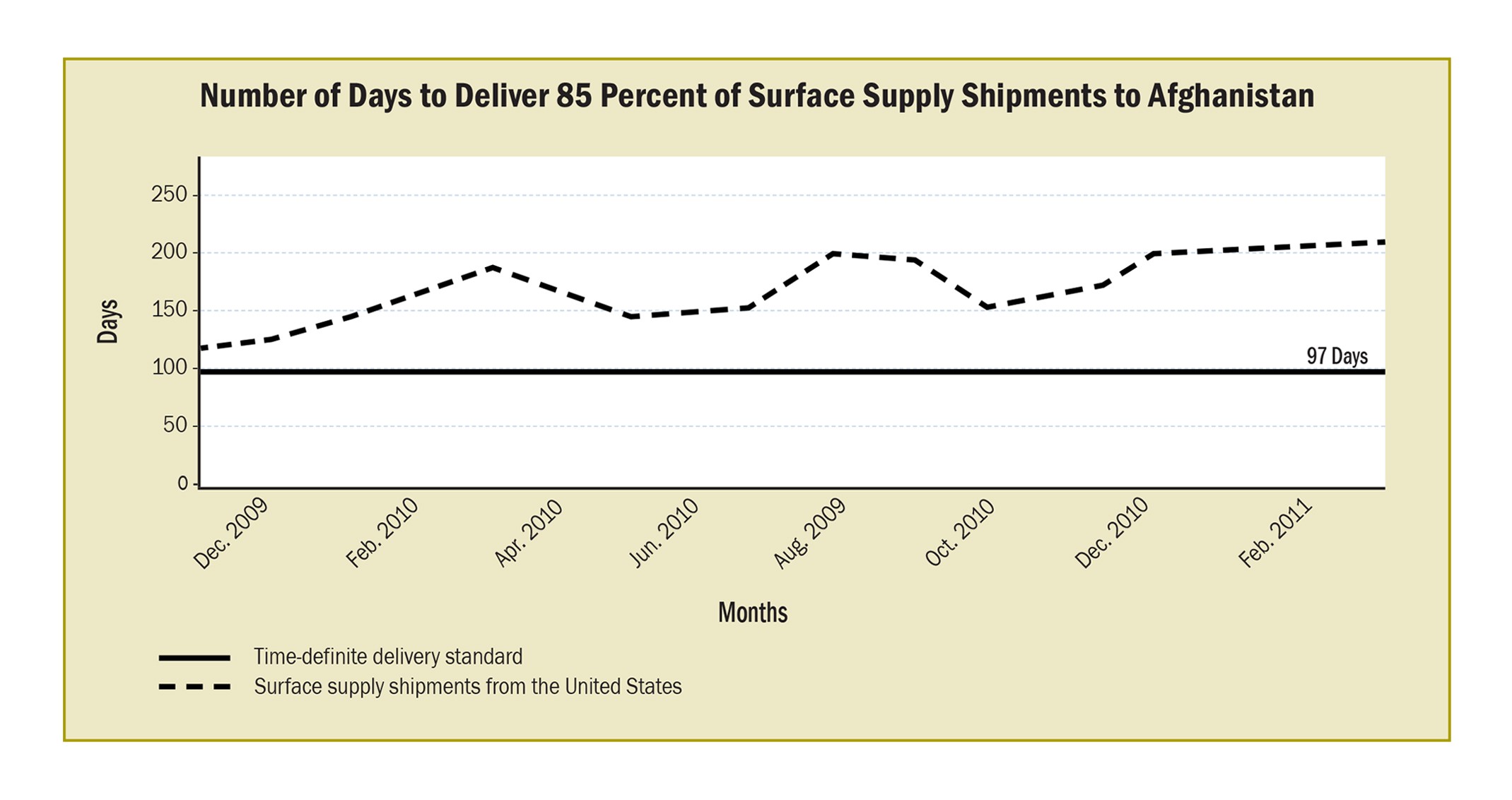

Procuring materials locally might also be more reliable. A 2011 report by the Government Accountability Office stated that the "DOD has not always met delivery standards and time lines for shipments to major logistics bases in Afghanistan … due in large part to the various difficulties in transporting cargo on surface routes through neighboring countries and inside Afghanistan."9 (See figure 2.)

Waste in the Army supply chain negatively affects combat power by making Soldiers wait for or go without needed supplies or by causing a crippling buildup of inventory. Locally sourcing supplies, as Freeport-McMoRan does, would lessen the requirements of the Army supply system and improve the delivery time of supplies to the front line, increasing combat power.

When moving into a remote location, one of the first requirements is class IV (construction materials). Soldiers need it to improve fighting positions, establish areas to operate out of, and improve their foxholes. Class IV is bulky and heavy, and it requires several transportation assets to move.

The Army's current solution when deploying to a remote area is to procure class IV at home station and transport the supplies to the forward location, moving it through every node along the way. This is expensive and time consuming, and it takes up valuable transportation assets that are needed for other critical items.

Locally procuring building materials would alleviate the requirement to ship class IV from the continental United States, increase the timeliness of arrival, and improve relations with the local population.

REGIONAL LOGISTICS EXPERTS

Army logisticians face significant challenges in navigating cultural boundaries and bureaucratic processes while resupplying troops in the field. Civilian corporations face these challenges every day, but they have logistics experts working with government officials, learning the bureaucracy, and adjusting their systems to provide seamless support.

Combatant commands are charged with contingency planning, but commands often lack the continuity and resources required for a deep understanding of regional challenges. The Army requires a team of professionals dedicated to making contacts with local support options, navigating bureaucracy, and learning from partnerships.

Local support options can free logistics and combat assets by reducing transportation requirements. Contracting local support can provide a tactical advantage to maneuver commanders through the good will garnered from conducting business with the local populace.

Regional experts can provide insight for military commanders into the feasibility of procuring supplies locally. They can focus on initiatives similar to those of their civilian counterparts in the area. They can serve on the ground to develop partnerships that will reduce the strain on the distribution network and free up scarce resources for combat power.

Cultural boundaries in the form of regulations, policy, and hostility are challenges to supporting remote locations. The reliability and consistency of shipments decrease with every border crossing. National borders are the most obvious challenges, but tribal and cultural boundaries also exist.

The regional experts can gain firsthand knowledge of each nation's requirements. They can understand the cultural landscape and calculate the impact on distribution networks throughout the region. The most efficient main supply route will often depend on the cultural landscape rather than distance and infrastructure.

It is not practical for the Army to conduct mock operations in remote locations to learn these lessons, but it is entirely feasible that a team of regional experts could partner with civilian corporations and agencies to gain invaluable insight before an operation.

The U.S. Agency for International Development funds an economic development project across Africa with the intent of reducing barriers to trade. The Trade Hub program understands how to move across borders, and it is actively campaigning to reduce border delays.

The East Africa Trade Hub program has reduced border crossing documentation by 10 percent, established main trade routes, and has an intimate knowledge of trade requirements.10 The Army should seek to benefit from this effort; regional experts would be the catalyst to ensure the information is shared.

COMMON PLATFORMS AND PARTS

In 2011, the Ford Motor Company released news about its global initiative to reduce the number of platforms used for Ford vehicles from 15 to five. This "economies of scale" initiative led to cost savings in engineering time, parts and service, and tooling and machinery.11

In 2014, Subaru announced the implementation of a new Subaru global platform for its vehicles. The initiative promises to cut unit costs by 20 percent by 2020 through "more efficient vehicle designs, standardized platforms, and leaner manufacturing processes."12

Freeport-McMoRan purchased 150 of its own cargo trucks to move supplies on the portion of its supply route where it experienced the most challenges and incurred the highest freight costs. The company wanted to handle the last tactical mile itself to reduce lead time, pilferage, and freight costs.13

The vendors wanted to sell the company three different brands of trucks. Freeport-McMoRan insisted on purchasing only one brand, and it procured 150 of the same trucks and 200 of the same trailers.

Purchasing the exact same trucks reduced the complexity of the supply chain of parts, the storage of parts and lubricants, operator training requirements, and mechanic training requirements. It also simplified communication with the manufacturer for maintenance expertise or warranty claims.

On the other hand, mine-resistant ambush-protected (MRAP) vehicles fielded in Iraq and Afghanistan consisted of different platforms with parts that were not interchangeable.14 The Army procured the MRAP as a stopgap measure to combat the improvised explosive device threat, but the challenges placed on the Army supply system as a result of the low commonality of parts between variants of MRAPs should serve as a lesson for future vehicle procurement.

As the Army moves forward in procuring the newly designed joint light tactical vehicle (JLTV), using common platforms and common parts should be a high priority. The Army has wisely insisted on 90-percent commonality of parts for the JLTV family of vehicles. This is a tremendous step in the right direction for the Army; unfortunately, it is only halfway.

To go the whole way, the Army needs to source vehicles with common parts between families of vehicles. The goal should be commonality of parts within the entire fleet of Army vehicles, not just within the JLTV family. The road toward that level of commonality is long, but the benefits would be worth it.

Tires, oil filters, mud flaps, light bulbs, belts, fans, and batteries can be shared across vehicle platforms. Picture having a light cargo truck, gun truck, and forklift that all share the same parts. Every vehicle has the same tires, same brake system, same lights, same battery, and same seat belt clips. This vehicle fleet would be ready for the most austere and logistically challenging locations on earth.

Common platforms, viewed from both the manufacturer's and end-user's perspectives, offer tremendous advantages. By embracing a more robust common platform initiative in the design and purchase of vehicles, the Army can reduce the logistics burden of parts, storage, transportation, operator training, mechanical expertise, and manufacturer support.

LOGISTICS COMMUNICATION SYSTEMS

In surveys conducted for this study, both Army professionals and civilian agencies listed communication as the leading cause of logistics problems that occur while resupplying remote locations and during operations in general.

The Army is often inefficient in supply distribution because of a lack of simple communication platforms that can accurately forecast the needs of those on the front lines. These platforms include in-transit visibility (ITV), inventory management, and the collection of historical data.

ITV is designed to provide near-real-time status on the movement of materials from supplier to user. The DOD defines ITV as "the ability to track the identity, status, and location of DOD units, and nonunit cargo (excluding bulk petroleum, oils, and lubricants) and passengers; patients; and personal property from origin to consignee or destination across the range of military operations."15

The Army uses this capability poorly; it does not adequately track the distribution of all classes of supply to remote locations. The Army's ITV scope and platform must be updated in order to become more efficient in resupply operations.

Providing decision-makers with effective ITV systems will allow for improved inventory management. The Army's current inventory management system is not synchronized in a manner that allows leaders at higher echelons to see the total logistics picture. According to a congressional report from the Government Accountability Office in 2012, the Army has $8.4 billion worth of excess inventory.16

Walmart and Caterpillar use advanced scanning mechanisms to track items from supplier to point of sale in real time. Walmart cashiers update the company's elaborate tracking system simply by scanning items that customers purchase when they check out, also called the point of consumption.17

In order to better manage resupply missions and, ultimately, resupply to remote locations, the Army should conduct research and make efforts to embrace technology that supports superior ITV and inventory management. Scanning capabilities that allow all classes of supply to be tracked to the point of consumption would significantly improve the Army's ability to manage inventory.

Companies are also more successful when they use collaborative forecasting and foster relationships with their suppliers.18 Companies within the supply industry use vendors to manage inventory, sharing demand data with suppliers to enable better forecasting.19

The Army often hires the lowest bidder. This practice is not strategic in nature and does not add value to inventory management. Whenever possible (when not tactically, operationally, or strategically detrimental), the Army should have suppliers manage and maintain inventory; this will simplify the supply chain and shorten lead time on deliveries.

The lack of a simple, dependable, and accurate ITV platform combined with inadequate inventory management results in historical data being lost and underused in forecasting supply operations.

With respect to logistics, the Army collects data, uses the information momentarily, and then dumps it. The Army's scanning systems do not have the capability to archive historical data that could be accessed easily by leaders and logistics professionals several years in the future.

For example, it would be extremely difficult for the logistics officer in the 2nd Brigade Combat Team, 101st Airborne Division, to retrieve the number of tires or the amount of fuel distributed to one of the brigade's maneuver battalions while in Mahmudiya, Iraq, in 2005.

The Army needs a simple, web-based, customizable system that collects historical data by location, unit, and class of supply. This data would be invaluable to forecasting the requirements of units in all locations, but especially in remote locations.

Keeping this data would also allow units to simulate demands in the supply chain during training events. These simulations would increase accuracy in forecasting and result in more efficient supply chains and, ultimately, an increase in combat power.

Civilian companies such as Caterpillar use a combination of methods to forecast. This global leader in mining equipment cited forecasting as its biggest competitive advantage.20

The Army needs to move in the direction of civilian agencies and improve communication systems in order to capture and use data to improve the logistics network.

POWER GENERATION

Freeport-McMoRan has instituted systems at its remote mining sites to turn waste into energy. These systems reduce the fuel requirement for base operations, save money, and reduce the strain on the distribution network.

They also provide the company with a responsible and safe manner in which to dispose of waste through the use of incinerators that cleanly burn used oil to produce energy.

The Army can adopt this method to reduce resource requirements at remote locations and improve combat power. In 2007, 50 percent of all Army convoys were dedicated to the transportation of fuel.21

Reducing the amount of fuel required to sustain operations would result in cost savings, a more efficient supply chain, increased asset utilization, increased operational flexibility, and increased combat power.

The Army has operated many combat outposts in Iraq and Afghanistan over the past decade-plus of war. These posts are located in remote areas next to small villages or town centers. Generators for operational power are mission-essential and are responsible for approximately 40 percent of remote base fuel consumption.22

Given the small quarters inside the combat outpost, efficient waste management is critical to both the health of the Soldiers on the post and the relationship with the local population. Waste is collected into one location at these sites and is burned to keep the amount of waste under control, often with serious and lasting negative health consequences.23

Implementing a modular waste-to-energy incinerator would offer the Army a solution to both of these issues. With this piece of equipment, the Army could provide energy to remote locations just by burning trash. And incinerators have been shown to produce fewer air particulates than open burn pits.24

Implementing waste-to-energy incinerators at remote locations would not only reduce the sites' logistics requirements and increase their operational flexibility; it would also be safer for the Soldiers.

Another problem is how the Army has been using its generators. Currently, the Army relies on generators to supply energy for base operations on remote locations. However, the Army is extremely inefficient in how it employs and operates these generators, and the consequences greatly hinder combat power.

At Camp Leatherneck, a remote base in Southern Afghanistan, "the 5 MW [megawatts] of demand is met by 19 MW of capacity, with 196 generators running at 30 percent capacity and consuming 15,431 gallons of fuel per day."25

Operating generators at 30 percent capacity results in "wet stacking." Wet stacking occurs when a generator is run with a minimal load, which causes the generator to use fuel more quickly and burn oil. It causes unnecessary wear and tear on the equipment, leading to higher maintenance requirements.

Fluor, a major defense contractor, highlighted the wet stacking of generators as a major focus for how they are striving to improve remote logistics support. According to Fluor's research, running the required number of generators at an 80-percent load factor would save 2,000 fuel tankers per year to one FOB.26

Simply running generators as they are designed to be run reduces the amount of fuel required, which reduces the number of convoys required, which improves combat power and saves lives.

If reducing the fuel requirements to a FOB is truly this simple, why is it not practiced more across the Army? The Army lacks the appropriate command emphasis and does not properly deploy knowledgeable Soldiers to enforce how generators should be operated.

The chairman of the Joint Chiefs of Staff, Gen. Martin Dempsey, recently stated that "our force will be smaller, so it must be more agile, more lethal, and postured to project power wherever needed."27 The path to achieve a more agile and lethal force capable of projecting power anywhere and anytime lies in creating logistics efficiencies.

The research conducted by the Maj. Gen. James Wright Program found six solutions to gain efficiencies in the supply chain. Through these efficiencies, the Army will be able to decrease waste, decrease delivery times, increase accuracy, increase asset utilization, and free up valuable funding that can be applied to increasing combat power.

_____________________________________________________________________________________________________

Maj. Linda C. Wade is a member of the G-8 Army staff. She holds a bachelor's degree in economics from the United States Military Academy, an MBA from the college of William and Mary, and a master's degree from Webster University.

Capt. Adam G. Bradford is a special assistant in the Office of the Chief of Staff of the Army. He holds a bachelor's degree in business administration from the University of Arkansas and an MBA from the College of William and Mary.

Capt. Timothy P. Gibbons serves at the Combined Arms Support Command at Fort Lee, Virginia. He holds a bachelor's degree in enterprise management technology from the University of Scranton and an MBA from the College of William and Mary.

Capt. Nathan D. Platz serves in the G-4, I Corps, at Fort Lewis, Washington. He holds a bachelor's degree in computer science from Missouri State University and an MBA from the College of William and Mary.

_____________________________________________________________________________________________________

This article was published in the January-February 2015 issue of Army Sustainment magazine. This article is a condensed version of the full paper "Increasing Combat Power through Smarter Logistics Support to Remote Areas" written by the authors. To access the full paper use the link provided above.

1 Michael S. Lasky, "What wineries can learn about sustainability from Walmart," Wine Business Monthly, December 2011, www.winebusiness.com/wbm/?go=getArticleeabb89c6987327e9abb61b6155e8b8ff0666e8164506384e90358b9195c9e6bd2c65ebded979595fcf6b980a0591bef25b3effa5a18d83b95294a8fe59b4a498dataid=94994.

2 John Kalkowski, "Walmart highlights sustainability efforts," Packaging Digest, March 4, 2012, www.packagingdigest.com/smart-packaging/walmart-highlights-sustainability-efforts.

3 Bill Dare (Freeport-McMoRan), personal interview, July 11, 2014.

4 "Sustainable Forward Operating Bases," Strategic Environmental Research and Development Program, May 21, 2010.

5 "MRE Packaging Factsheet," U.S. Army Natick Soldier Research, Development, and Engineering Center, provided by Dr. Jo Ann Ratto.

6 Bill Dare (Freeport-McMoRan).

7 "Sustain the Mission Project: Casualty Factors for Fuel and Water Resupply Convoys Final Technical Report," Army Environmental Policy Institute, Arlington, Virginia, September 2009, http://www.aepi.army.mil/docs/whatsnew/SMP_Casualty_Cost_Factors_Final1-09.pdf.

8 Ibid.

9 "Warfighter Support: DOD Has Made Progress, but Supply and Distribution Challenges Remain in Afghanistan," Report to Congressional Addressees, Government Accountability Office, October 2011.

10 "USAID East Africa Trade Hub Fact Sheet," U.S. Agency for International Development, Feb. 28, 2014, http://www.competeafrica.org/Files/EA_Trade_Hub_Fact_Sheet_December_2013_Trade_Africa.pdf.

11 Mike Ramsey, "Ford SUV Marks New World Car Strategy," The Wall Street Journal Online, Nov. 16, 2011, http://online.wsj.com/news/articles/SB10001424052970203503204577040343509436550.

12 Hans Greimel, "Subaru plans more U.S. capacity, unveils new technology," Automotive News, May 9, 2014, http://www.autonews.com/article/20140509/OEM/140509810/subaru-plans-more-u-s-capacity -unveils-new-technology.

13 Bill Dare (Freeport-McMoRan).

14 David Vergun, "JLTV testing begins, program on schedule, budget," Army News Service, September 5, 2013, www.army.mil/article/110710/JLTV_testing_begins_program_on_schedule_budget/.

15 Army Regulation 700--80, Army In-Transit Visibility, Oct. 24, 2008.

16 "Defense Inventory: Actions Underway to Implement Improvement Plan, but Steps Needed to Enhance Efforts," Report to Congressional Committees, Government Accountability Office, May 2012, http://www.gao.gov/assets/600/590607.pdf.

17 Todd Traub, "Wal-Mart Uses Technology to Become Supply Chain Leader," Arkansas Business, July 2,2012, http://www.arkansasbusiness.com/article/85508/wal-mart-used-technology-to-become-supply-chain-leader?page=all.

18 C. Deloitte, personal interview, July 30, 2014.

19 Ibid.

20 Paul R. Cusack (Caterpillar), personal interview, July 25, 2014.

21 "Sustain the Mission Project: Casualty Factors for Fuel and Water Resupply Convoys Final Technical Report."

22 "Sustainable Forward Operating Bases."

23 Harrison Jacobs, "The Military's Open-Air Burn Pits Have Left A Generation Of Troops With Health Problems," Business Insider, Nov. 5, 2013, http://www.businessinsider.com/open-air-burn-pits-leave-troops-sickly-2013-11.

24 Jeff Schogol, "New incinerators to aid air quality in Kandahar," Air Force Times, Oct. 22, 2012, http://www.airforcetimes.com/article/20121022/NEWS/210220302/New-incinerators-aid-air-quality-Kandahar.

25 "Sustainable Forward Operating Bases."

26 David Vaughn and Tony Montalvo (Fluor), personal interview, July 28, 2014.

27 Martin E. Dempsey, "The Bend of Power," Foreign Policy, July25, 2014, http://www.foreignpolicy.com/articles/2014/07/25/the_bend_of_power_us_leadership_military_martin_dempsey.

Related Links:

Browse January-February 2015 Magazine

Full Remote Sustainment Final Report

Army Sustainment Magazine Archives

Social Sharing