REDSTONE ARESENAL, Ala., June 13, 2011 -- While working on Redstone Arsenal, Ala., college students are learning that microwaves are not for just cooking food.

A group of students and professors from Texas Tech University recently came together with engineers and staff members of the U.S. Army Space and Missile Defense Command/Army Forces Strategic Command, as well as the Aviation and Missile Research, Development, and Engineering Center, at Redstone Arsenal, to demonstrate high-power microwave generation with an explosive-driven compact system.

The tests conducted here are part of a Small Business Innovative Research contract USASMDC/ARSTRAT has with Texas Tech University.

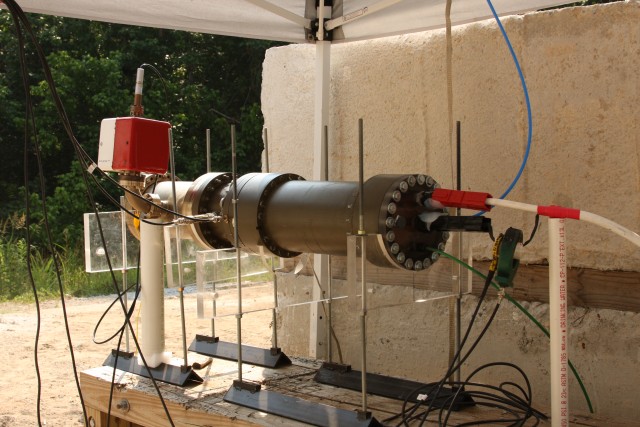

"Being here at Redstone Arsenal has been a great learning experience," said Moe Elsayed, a research associate at the Center for Pulsed Power and Power Electronics at Texas Tech. "A lot of work and effort has gone into the program. It is a very complicated system and we have been able to get a lot of power into a 6-inch diameter. We completed our first tests here in 2009, and what we have learned and been able to accomplish by minimizing the current size from where we started is still amazing."

Elsayed explained how the main capacitor stores initial energy that is dumped into a Flux Compression Generator. Lithium ion battery packs are used to charge the capacitor in approximately 125 milliseconds to a voltage of 3 kilovolts.

Approximately 180 joules of energy is then transferred to the Flux Compression Generator. Once that initial energy is dumped to the generator, then you have the process start with the explosively driven pulse power.

He said you then take the initial energy, establish a magnetic field, detonate the explosives, compress the magnetic flux, get a high-current output and from the high-current output you have a power conditioning system that takes the high current and conditions it into a high-voltage signal and the high voltage turns on the microwave or virtual cathode oscillator, or VIRCATOR, source.

"This is a program that helps our students learn and understand what you can get out of explosive-driven pulse power, electric explosive fuses, diagnostic measurements and design," Elsayed said. "We were given a task to design something that can radiate maximum power within a specific size constraint and how can we do it. We are learning what we can do when we all start working toward a specific goal."

One of the objectives for the students is to train them in the design and application of compact explosive-driven pulsed power. The program is important to the university and to the students because the Center for Pulsed Power and Power Electronics is the only university in the U.S. where students can learn the set of skills needed for compact explosive-pulsed power.

"We have learned that if you improve one component, it also helps the others and improves the performance of the entire system," said Andrew Young, a graduate student at Texas Tech who will receive his doctorate in less than a month. "This has been a great experience. The biggest challenge with putting this in such a small package is that it experiences very high current and very high voltage during the system operation, so you have to be able to insulate everything and you have to allow for adequate conductor cross section.

"Obviously, developing all the integration between the components has been key because you need to ensure everything comes together to make it work," he added. "I am proud that we have seen significant improvement from year to year. We keep giving it more and more capability but also making it smaller and smaller. It is a unique system and I am proud to have been a part of its development."

According to Larry Altgilbers, general engineer at the USASMDC/ARSTRAT Technology Center and project lead for the command, the students are working with explosive-pulsed power, high-power microwaves and high voltage engineering.

The students worked with a Flux Compression Generator, which converts chemical energy into electrical energy that is used to power the microwave tube. Since last conducting tests on Redstone Arsenal in 2009, one of the goals of the students has been to miniaturize and improve the device.

A set of antennas measured microwave output at various distances to measure microwave output by the Flux Compression Generator.

"This is a very significant example of a good university research program where we have actually produced something and continually improved it," said John Walter, Texas Tech senior research associate. "We have continued to give it more capabilities while also reducing it to where it now fits in a 6-inch diameter tube."

As testing continues on Redstone Arsenal Test Area 10, members of the installation discussed the importance of having post entities as well as the students come together on the project.

"The effort has been a joint one because of funding issues and we found out very early that working together is better for these projects," said Allen Stults, AMRDEC Weapons Integration Directorate research engineer. "It has been a very synergistic effort and we have brought the Texas Tech students here because they work well on integrating all the components and they have been very successful, and we are proud to have helped them be successful."

Related Links:

U.S. Army Space and Missile Defense Command

Social Sharing