PICATINNY ARSENAL, N.J. (Jan. 17, 2013) -- It's the summer of 2005 and a squad of New York Army National Guard Soldiers is on patrol in Iraq. In an instant, their medic is struck by a round fired from an insurgent.

But just as quickly, the medic springs back up and moves to cover, pointing in the suspected direction of fire.

The Soldiers give chase and catch up to one of the insurgents, who has been injured in the pursuit. The medic treats the insurgent's wounds, saving his life.

The medic's own life is saved by the ceramic body armor plate he is wearing.

The ceramic armor he wore, dubbed Small Arms Protective Insert, or SAPI, is standard issue to Soldiers and is an integral part of the Outer Tactical Vest, or OTV, body armor system.

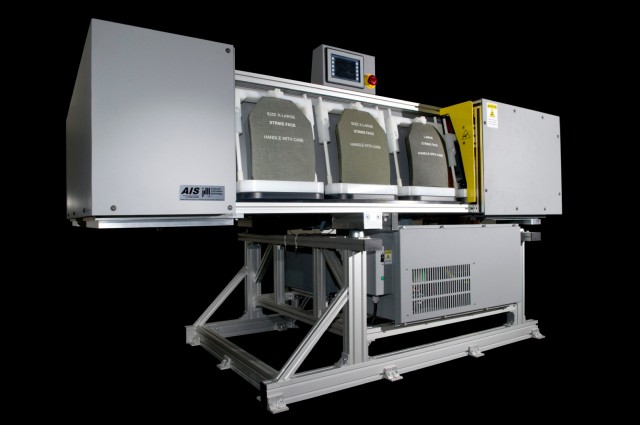

Ensuring the integrity of those plates is a task undertaken by the Quality Engineering and System Assurance, or QE&SA, Directorate of the U.S. Army Armament Research, Development and Engineering Center at Picatinny Arsenal, which developed the Armor Inspection System.

In early 2005, representatives from Project Manager Soldier Survivability of Fort Belvoir, Va., the organization responsible for the armor plates worn by Soldiers, approached QE&SA personnel in the Radiographic Laboratory to ask if it was feasible to inspect the ceramic armor plates.

"Being a ceramic, these SAPI plates are a glass and like all glasses are brittle and prone to cracking," said Lawrence J. D'Aries, QE&SA's chief scientist for Non-Destructive Evaluation.

"In effect, these SAPI plates work in conjunction with the Kevlar backing in the plate carrier and effectively acts as a two-step countermeasure."

When a round or fragment strikes the armor, the SAPI plate absorbs the kinetic energy of the incoming projectile by effectively shattering and dispersing the impact over a larger surface area.

The Kevlar backing acts as a shield to stop the shattered shards of ceramic from penetrating into the Soldier, D'Aries said.

The combination of ceramic armor and Kevlar backing has proved effective in combat. But there's a drawback to the use of ceramic armor because they are prone to cracking.

"Naturally, such cracking could degrade the ballistic integrity of the plate," said D'Aries.

Wearing armor that is susceptible to cracking could have serious consequences for Soldiers who depend on it.

But how do you test the integrity of something that is rigid, and yet fragile, without damaging it?

"Many non-destructive inspection techniques were tried in the past but none proved to be both possible and feasible," D'Aries said. "Since our expertise at the Radiographic Lab is in radiographic (X-ray) inspection, this was the next and last technique to try."

After a day of experimentation and test shots using various X-ray sources available at the lab, the scientists and engineers discovered that X-ray inspection was a viable solution.

"What was yet to be seen was whether it was going to be feasible to implement," D'Aries noted.

To be feasible, any inspection system would need an automated material handling system to load and unload the plates into the testing system, along with the ability to quickly detect if a plate was cracked.

"With, on the order of over a million SAPI plates that required inspection, this task was going to be a great challenge," D'Aries said. "In addition, these plates were in multiple places around the world, so logistically it was not feasible to ship them all to a single inspection location. Multiple systems would be required worldwide."

As a result, the Armor Inspection System, or AIS, prototype was developed with the assistance of a small business contract with JDLL, Inc., of Midvale, Utah, over the next 14 months.

The prototype was first deployed to Kuwait in 2008.

"It performed admirably and further improvements in the hardware and software over the next few years resulted in the current ownership and deployment of a soon-to-be total of 18 AIS systems by the U.S. Army, U.S. Marine Corps and the U.S. Navy to five overseas locations and multiple locations in the United States," said D'Aries.

"Most of the items developed at ARDEC are offensive weapons," D'Aries said. "Although this is the story of assuring the ballistic integrity of body armor, a defensive 'weapon,' there is probably no other piece of equipment issued to our troops that is more important."

Related Links:

Picatinny recycles artillery shells to create cheaper, safer, more realistic training rounds

Army labs join forces for healthier smokes

Fort Bliss Soldiers first to fire Army's new near-precision artillery rounds

M2A1 Machine Gun features greater safety, heightened lethality

Army's newest general purpose round shows accuracy in rifle competition

Explosive waste incinerator at Picatinny reduces need for open burning

Seeking a safer pyrotechnic delay

Armament Research, Development and Engineering Center (ARDEC) website

Social Sharing