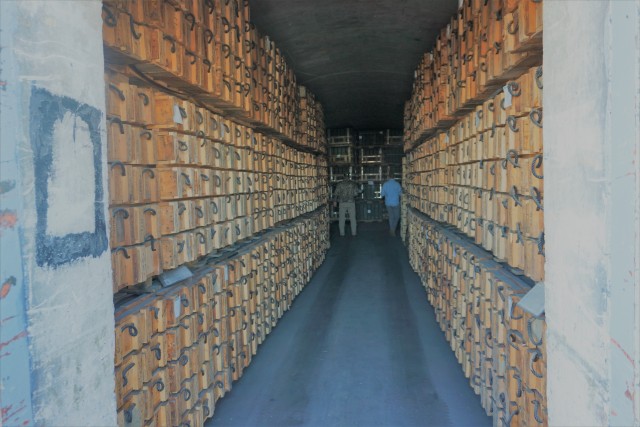

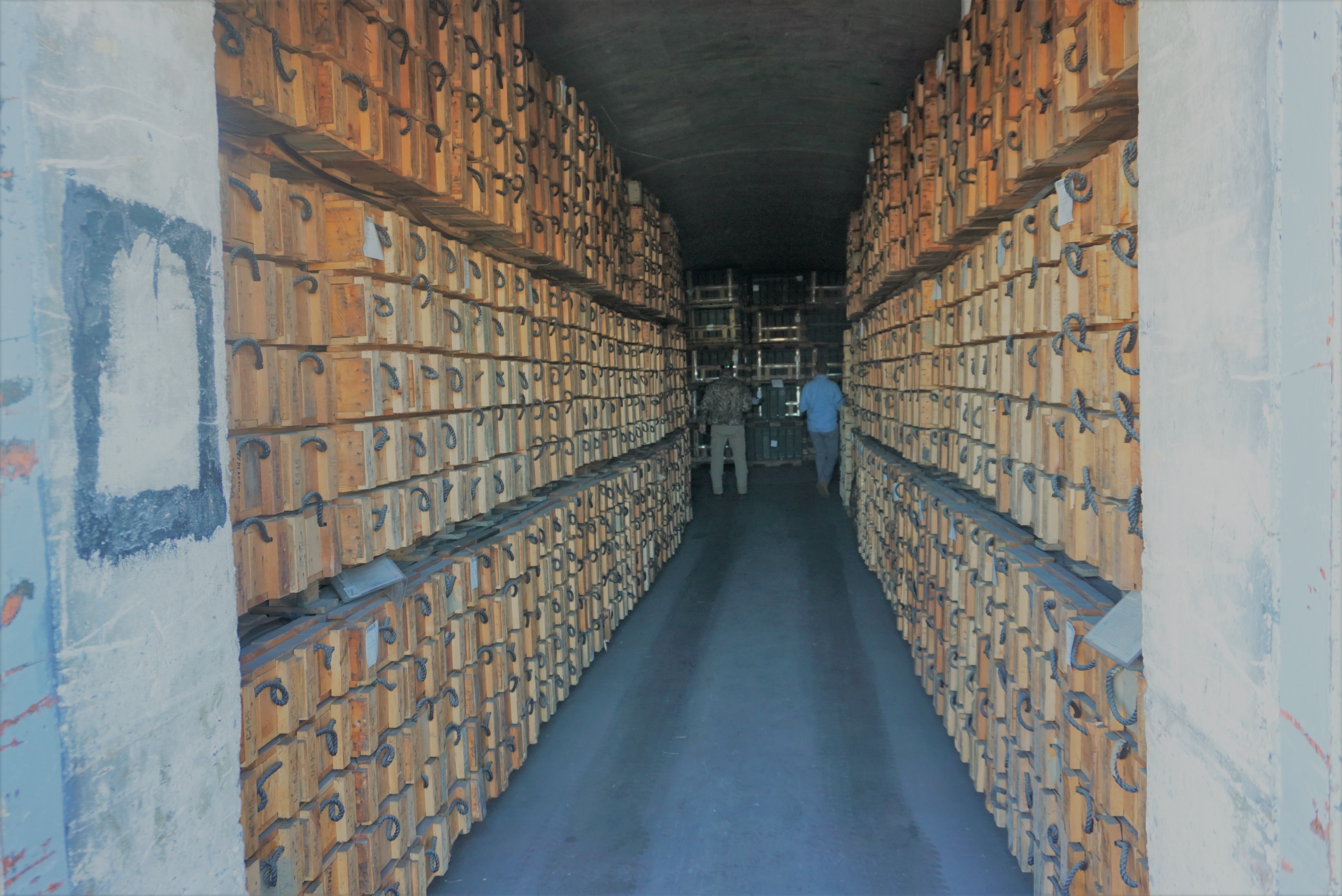

Exceeding expectations … that is how auditors and the U.S. Marine Corps described their yearly audit of munitions at Tooele Army Depot. The audit ensures the accountability and security of the munitions on TEAD and is just one of the many audits and inspections conducted at the Depot.

Two teams comprised of staff from TEAD, Joint Munitions Command, the Marine Corps and independent auditors spread out across the Depot to check the Marine’s munitions.

“We are reporting what we are supposed to have and what we have on hand is actually what is on the books,” said Paul King, U.S. Marine Corps program manager.

The auditors conducted 62 book-to-floor checks—making sure what is in the computer inventory is what is in storage, and 120 floor-to-book checks—matching up what is in storage to what is in the computer inventory. Auditors only planned 62 floor-to-book audits, but the TEAD team was so efficient they doubled their output.

“The fact that you were able to get through so many samples in a short period of time means our team had things set up and ready to go,” said TEAD Commander, Col. Steven Dowgielewicz. Everyone involved in the audit applauded the preparedness and efficiency of the TEAD team.

JMC personnel serve as a liaison between the facility and the auditors.

“We provide seamless transition between the sites, so they [the auditors] don’t get all these variations as far as paperwork, communication, documentation and processes,” said Mitch Driscoll, JMC logistics management specialist.

While TEAD and other JMC facilities store the munitions, JMC is still technically the organization being audited. If the auditors issue any findings, the JMC team would work with the facility to fix them.

Auditors found no major findings during their three days at TEAD. They did make a couple minor recommendations like ensuring all lot numbers are facing out on pallets.

“I appreciate it when we can get an outside team in to look at what we are doing, and let us know what we are doing right and where we can do better,” said Dowgielewicz.

Social Sharing