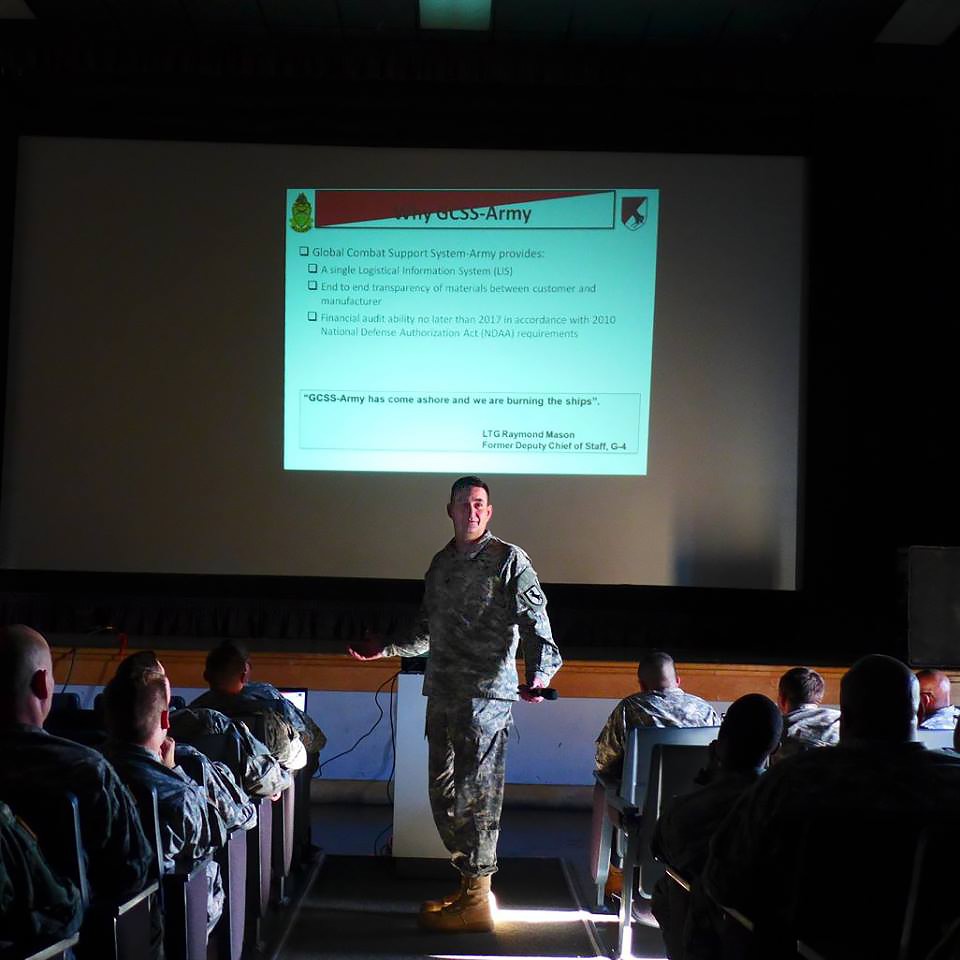

Over the past several years, the 11th Armored Cavalry Regiment (ACR) has fielded the Global Combat Support System-Army (GCSS-Army). GCSS-Army Wave 2 is being deployed to fielding groups throughout the Army, and the knowledge the 11th ACR has acquired could potentially ease the transition.

While Wave 1 of GCSS-Army provided access solely to supply support activity functions, Wave 2 also provides commanders with maintenance, dispatching, unit supply, and property book functions.

ROLES IN GCSS-ARMY

GCSS-Army has numerous user roles. Each role is based on a military occupational specialty or leadership position.

At the company level, commanders' rights enable them to view multiple types of transactions in their organization and approve dispatches and other basic functions.

These rights can be delegated to other members of the unit, such as the executive officer. The executive officer, being the supply and maintenance officer for the company, can have the rights to view exactly what the supply room and maintenance sections are doing.

Motor sergeants have a different role--one that allows them to read and write in several maintenance functions. The supply sergeant has similar rights that apply solely to the supply room.

MAINTENANCE

Being mission capable starts with maintenance operations and is vital to unit readiness. GCSS-Army allows members of the chain of command to pull equipment status reports (ESRs) to see which vehicles are not mission capable. (Information is pulled from the ESR using the transaction code Z_EQUST.)

The ESR provides data about a piece of equipment and, more importantly, the status of parts on order to correct faults. Commanders have this ability with the Standard Army Maintenance System-Enhanced; however, GCSS-Army gives them the flexibility to pull this information from any location along with the vehicle's history and unit financial information. These functions allow the commander to make timely decisions without the delay of external reports.

Using the ESR, the commander or executive officer can determine the dead-lining fault, the estimated ship date of the repair part, and the current location of the inbound part. GCSS-Army also allows the chain of command to see the vehicle's status history and who conducted the last service on the vehicle.

DISPATCHING

Once parts are received and the vehicle is fully mission capable, dispatching occurs. After the end-user has completed the Department of the Army Form 5988-E, Equipment Inspection and Maintenance Worksheet, the information is uploaded into GCSS-Army.

Pulling information from licensing functions built into the system, a clerk and dispatching personnel can immediately see if the operator is properly licensed. Although it does not replace premovement checks and inspections, it serves as an additional check to ensure personnel are only using equipment they are certified to operate.

Once the company's prescribed load list clerk completes the dispatching packet, the information is sent to the dispatching authority through GCSS-Army. Using the Systems, Applications, and Products in Data Processing (SAP) Business Workplace T-code, an approver can view who is trying to dispatch a vehicle before approving it.

With the ability to dispatch from afar with a single click comes the potential loss of face time in the motor pool. However, the advantage of being able to multitask may outweigh this risk.

SUPPLY

As the manager of the commander's hand receipt, the supply sergeant uses GCSS-Army to keep supply functions up to date. Property Book Unit Supply Enhanced is a stovepiped system and has difficulty pulling information from other systems, but GCSS-Army uses information from other systems with similar coding. This makes ordering expendable class II (clothing and individual equipment) items easier.

Once an order has been placed, it progresses through different automated gates and gatekeepers before the order is confirmed. One of these gates is the T-code ME5A, a list of purchase requisitions that can be accessed by budget officers. ME5A and other gates ensure that the right item is put on order and information that is entered incorrectly is more noticeable.

Once an item has passed through the purchasing process, T-codes such as VL06I, the inbound delivery monitor, can be used to determine its status in the Army supply system. After the order has been verified, it can be tracked until it arrives at the supply support activity for pickup.

PROPERTY BOOK

After pickup, the supply sergeant can move the item within GCSS-Army by assigning it to a storage location, where a clerk will update the commander's hand receipt. This ability allows for automatic updates in the system to sub-hand receipts and plays a large role in the change of command inventory process.

For both the incoming and outgoing commanders, the change of command inventory is incredibly important. For this purpose, GCSS-Army can generate the primary hand receipt, sub-hand receipts, and hand receipts for basic issue items and components of the end items.

Once the verification of all end items is complete, the numbers can be entered into GCSS-Army to create a base document for the commander and the sub-hand receipt holders. This document can be updated in the system, removing the need for excessive amounts of paper hand receipts.

Platoon leaders and platoon sergeants can also visit their respective storage locations in GCSS-Army and digitally sign their hand receipts, making the inventory process easier.

At the company level, GCSS-Army streamlines operations and reduces the number of redundant systems. The enterprise nature of GCSS-Army reduces the amount of time commanders and leaders spend on clerical tasks and increases the amount of time they spend on training forces.

_____________________________________________________________________________________________________

Capt. W. Sean McGill is the commander of the Supply and Transportation Troop, Regimental Support Squadron (RSS), 11th Armored Cavalry Regiment (ACR). He has been with the 11th ACR for the past two years and also served as the RSS operations officer. He holds a bachelor's degree in business administration from Radford University and is a graduate of the Combined Logistics Captains Career Course.

1st Lt. Evan M. FitzGerald is the executive officer for the Regimental Headquarters and Headquarters Troop, 11th ACR. He has served in the 11th ACR for the past three years, also holding positions as a platoon leader, executive officer, and support operations plans officer. He holds a bachelor's degree in human communications from California State University Monterey Bay and a master's degree in transportation and logistics management from American Military University. He is a Demonstrated Master Logistician, a Certified Lean Six Sigma Black Belt, and a Certified Associate in Project Management.

_____________________________________________________________________________________________________

This article was published in the July-August 2015 issue of Army Sustainment magazine.

Related Links:

Browse July-August 2015 Magazine

Army Sustainment Magazine Archives

Social Sharing