Lean improvements made to an Army radio system's repair process are becoming the model for all shelter system repair methods used at Tobyhanna Army Depot.

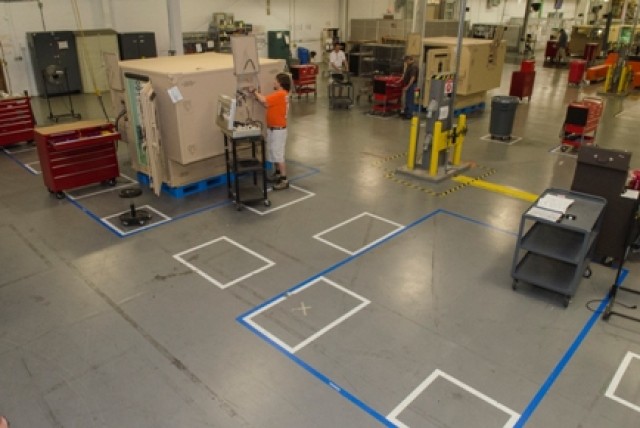

The Shelter Enterprise Value Stream's moving repair line was established to stabilize and standardize the AN/TRC-190 High Capacity Line of Sight Radio Terminal Reset process. The moving line is made up of a series of sites each shelter progresses through. The shelter moves to employees rather than employees moving to the shelter.

Various improvements were implemented to stabilize and standardize the AN/TRC-190 Reset processes, including standard work/key point sheets, standardized inspection checklists, a central kitting area and kit cages, point-of-use material, process tool boxes, visual management, and production control board.

By introducing point-of-use materials, excess inventory decreased and a cost avoidance of $205,225 was achieved. A new strategy led the repair team to deliver [or pull] shelters based on demand instead of scheduling production [day-to-day] to meet anticipated demand, then pushing them through the process.

Direct labor hours have decreased by more than 20 percent and travel distances were cut by 75 percent. In some cases, in-process queue times were reduced by as much as 10 days, which reduced work-in- progress.

Social Sharing