KIRKUSH MILITARY TRAINING BASE, Iraq - The Kirkush Military Training Base Logistics Training Advisory Team, consisting of Soldiers from the 602nd Support Maintenance Company, 356th Quartermaster Company and the Headquarters and Headquarters Company, 259th Combat Sustainment Support Battalion have been mentoring the Kirkush Repair and Maintenance Company of the 5th Iraqi Army in Diyala province since Dec. 2008.

This mentorship and collaboration has been paramount in transferring skills and knowledge to an Iraqi Army unit in order to develop their own maintenance work practices.

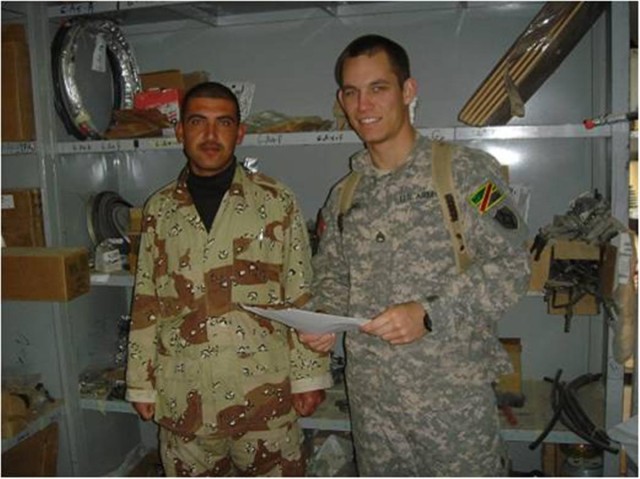

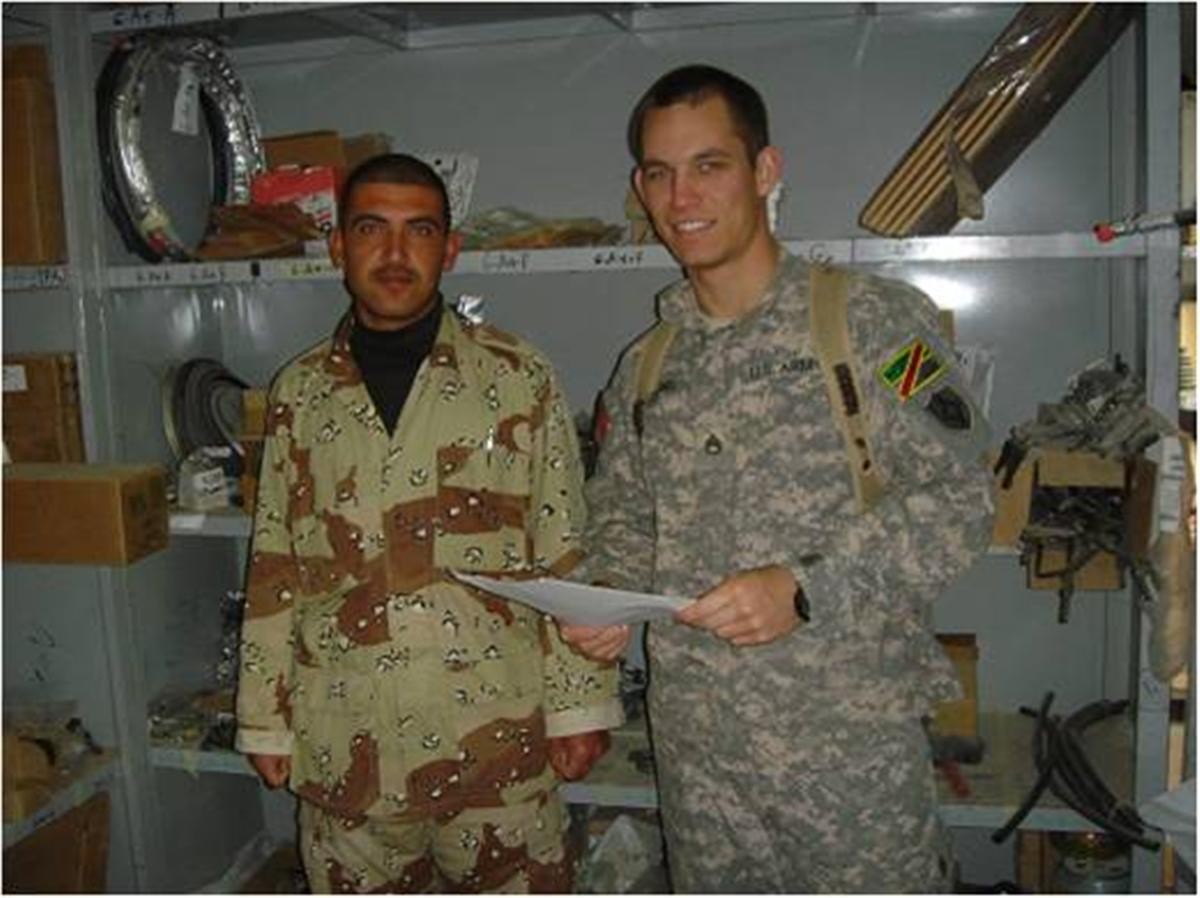

Sgt. Mark Bauer, a Killeen, Texas resident, from the 602nd Maintenance Company of Fort Hood, Texas, said his unit played a pivotal part of the Iraqi advisory endeavors.

Bauer said they work diligently with their Iraqi counterparts while instructing the Iraqi officers on vehicles and parts status and implementing preventive maintenance measures of their equipment. This is to ensure safe maintenance practices, he said.

In addition to Bauer, two Ocala, Fl., based 356th QM Co. noncommissioned officers also train the Iraqi Soldiers on the logistics aspects of the maintenance and warehouse operations.

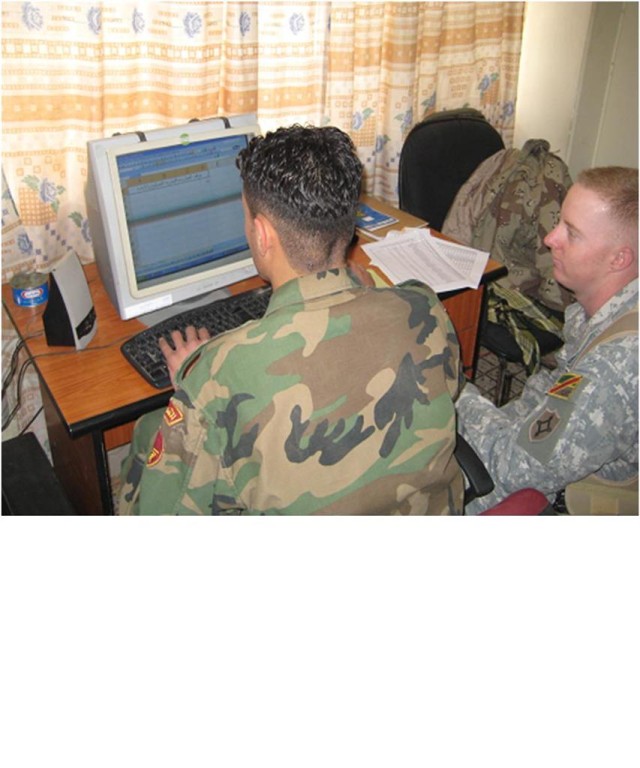

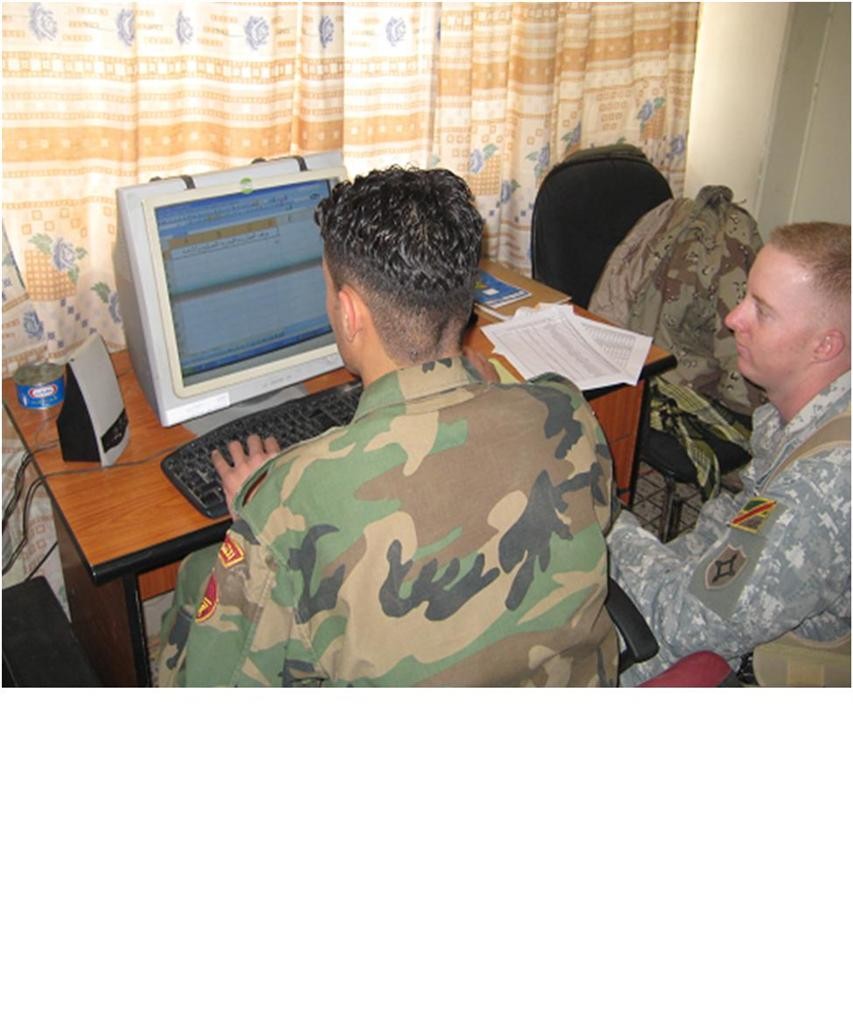

Sgt. Michael Ammons, taught the Iraqi Soldiers how to use the Iraqi Army Maintenance Program (IAMP) and was developed by ANHAM LLC., a Colorado based logistics contractor that provides equipment work order status and information. The system is similar to the U.S. Army logistics Standard Army Maintenance System - Enhanced (SAMS-E).

Staff Sgt. David Timmons, trained the warehouse operations procedures to process receipts, storage, issuing and accountability of Class IX repair parts. This process will facilitate timely repairs and return of equipment.

The LTAT has accomplished a lot in a relatively short time while allowing the Iraqis to gain trust and confidence in their own system. The LTAT mentorship is one part of training the Iraqis to eventually become self-sustaining.

Social Sharing