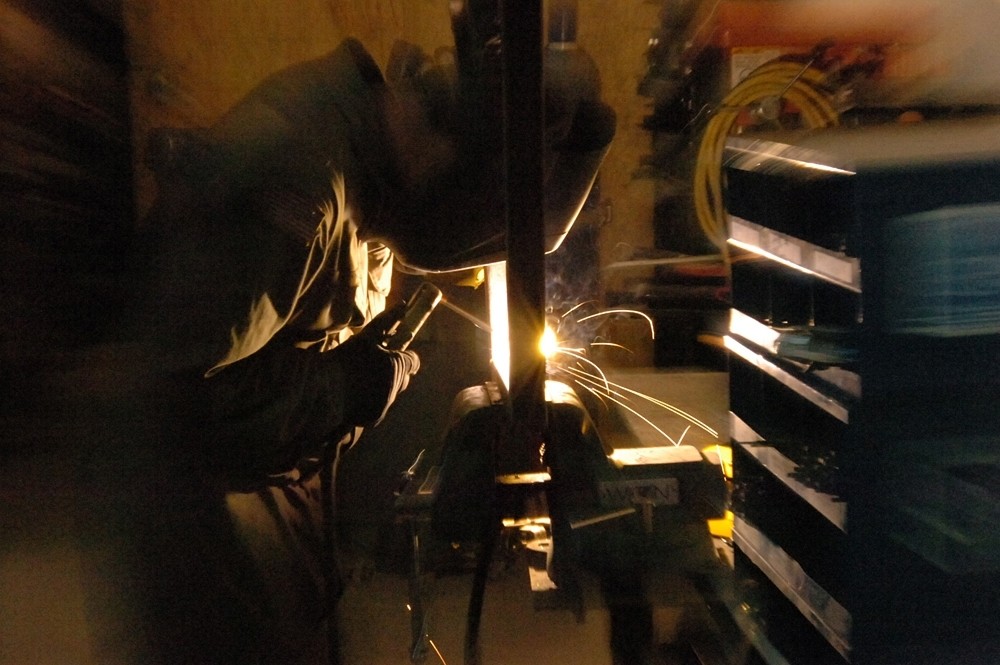

FORWARD OPERATING BASE UNION III, Baghdad (Army News Service, Jan. 31, 2007) - Mechanics from the 1st Cavalry Division are setting a quick pace and high standard for vehicle repairs here.

When the Soldiers from Headquarters and Headquarters Company, 3rd Battalion, 82nd Field Artillery Regiment, 2nd Brigade Combat Team assumed operations, the shop was already behind by more than 30 vehicles in need of repair. Not only did they catch up, they've taken on the job of servicing more than 700 vehicles from all the different coalition elements on the base.

"Most of the auto mechanics we have take a lot of pride in the work that they do ... not only turning out product for the battalion but for all the other people on the FOB," said Warrant Officer Shane Steele, 3rd Bn., 82 FA Regt.

The 19-Soldier platoon maintains more than 100 vehicles for the battalion, including Humvees, cargo haulers and the battalion's claim to fame: the massive Paladin.

Many of the mechanics had have never worked on a Humvee before joining the unit.

Pfc. Justin Cassella said that although he's a generator mechanic, working on the armored Humvee gives him a good opportunity to learn.

"I worked on vehicles before I joined the military," Cassella said. "I didn't want to do it again, but this gives me good experience. I learn more and more every day."

His platoon sergeant cited positive attitudes like Cassella's as one of the main reasons the shop is so successful.

"Dedication and hard work are just what these guys are made of," said Sgt. 1st Class Carlton Parkhurst. "The best thing is they catch on quick. You show them how to do something once and they've got it."

Even Georgian Army soldiers at the base have reaped the benefits of the shop's "can-do" attitude. Steele said the Georgians' trucks went from getting no maintenance to getting serviced, to having a fully-operational force since his mechanics arrived about a month ago.

Although the shop's mission seems large enough, the Soldiers have additional duties that go beyond repairing trucks and tracks.

"The biggest challenge we have is everyday missions like FOB security and troop- to-task missions on top of our heavy workload," Steele said.

"Just trying to keep the balance of the right amount of people in the motor pool while maintaining everything else the battalion needs along with the maintenance we already do is tough, but we get it done," he said, adding that he's heard nothing but rave reviews for his Soldiers and their work.

(Spc. Alexis Harrison writes for the 2nd Brigade Combat Team, 1st Cavalry Division.)

Social Sharing