FORT CARSON, Colo. — A distinct hum and sharp buzz slice through the air inside the Ivy Eagle’s “Monster Garage.” The sounds emanate from a football-sized quadcopter, its rotors a blur as it expertly maneuvers around a complex, custom-built obstacle course.

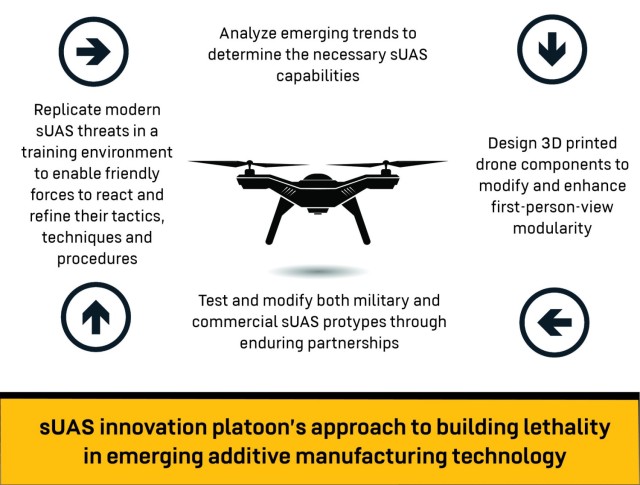

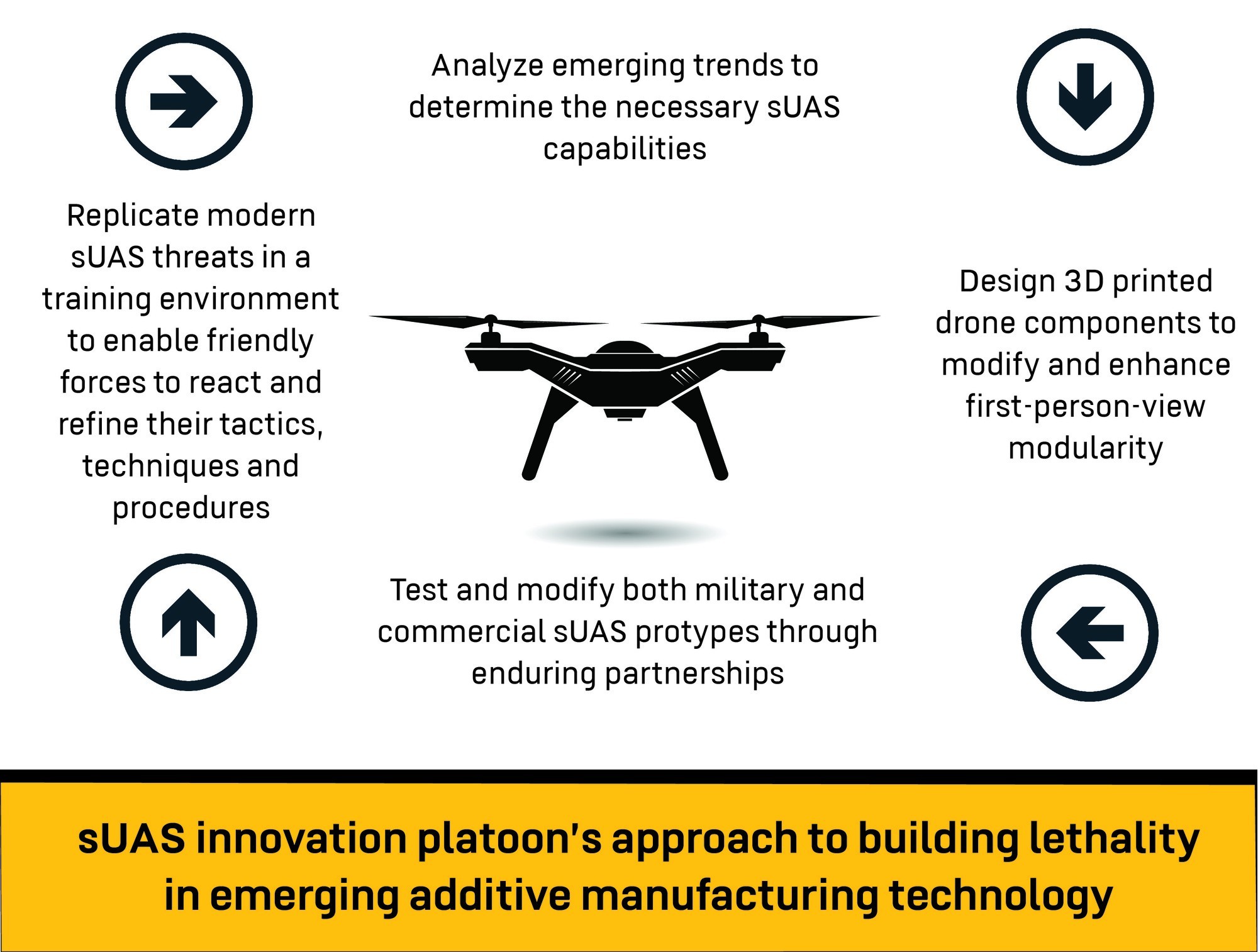

The modern battlefield demands agility, adaptability, and technological superiority. Small unmanned aerial systems, sUAS, and 3D printing, also called additive manufacturing, technology have emerged as critical assets in achieving these objectives, providing essential reconnaissance, surveillance, target acquisition, electronic warfare and logistical support capabilities.

Pilots from the 4th Infantry Division’s sUAS Innovation Platoon, the “Dragonflies”, practice their maneuvering skills at the “Monster Garage” with the use of laptop-based simulators before progressing on to the obstacle course in the warehouse and completing larger field exercises to demonstrate how sUAS are playing a crucial role in the operational environment.

Brig. Gen. Eugene Ferris, the division’s former deputy commanding general for maneuver, said that the future of modern warfare will depend on the lethal integration and the effective deployment and sustainment of sUAS in dynamic and often contested environments, which are paramount for mission success.

Small Unmanned Aerial Systems

In military operations, sUAS serve many critical roles, providing real-time intelligence, enabling precision strikes, conducting electronic warfare, and even facilitating resupply in challenging environments.

The effectiveness of the sUAS Innovation Platoon, 6th Squadron, 17th Cavalry Regiment, 4th Combat Aviation Brigade, 4ID, in these varied and crucial roles is further amplified by the ability to tailor their designs for specific, demanding environments.

“For the 4ID and 4CAB, the ability to rapidly prototype and adapt sUAS designs is critical when operating in diverse and complex environments”, said 1st. Lt. Nicholas McDonald, platoon leader for the Dragonflies. “The performance characteristics of these systems extended flight endurance for persistent surveillance, low observability for stealth and robust construction for survivability.”

For the division, these advantages translate into tangible operational benefits: customizing sUAS to carry specific payloads or intelligence packages for information gathering, quickly prototyping and testing new sUAS configurations and integrations during training exercises to adapt to future threats.

The dynamic nature of military operations often necessitates swift responses to emerging threats or rapidly evolving tactical situations, empowering the 4th Infantry Division and the broader military to quickly translate urgent operational needs into tangible solutions for sUAS.

Additive Manufacturing

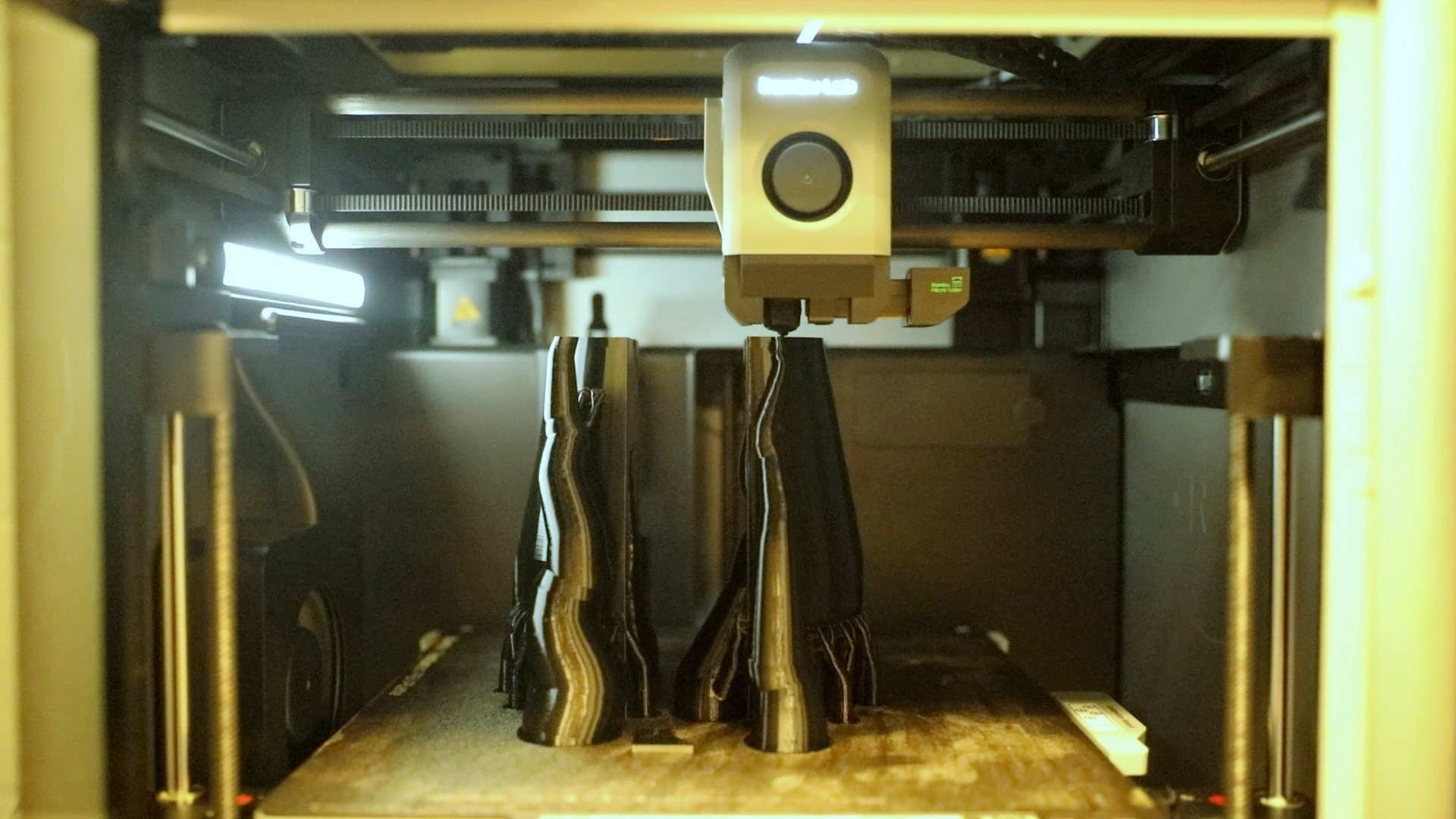

Additive manufacturing, or AM, is a transformative technology that revolutionizes how the military develops, deploys and maintains its sUAS fleets, offering unprecedented agility, customization and enhanced operational readiness.

Beyond conventional prototyping, AM enables the production of complex, lightweight components crucial for maximizing the flight performance of sUAS, reducing their signature and increasing their payload capacity. These demanding requirements necessitate the use of advanced materials and highly optimized designs, areas where AM offers significant advantages over traditional manufacturing methods.

Ferris explains that AM technologies offer specific benefits for military applications. The inherent flexibility of AM allows for integrating features that enhance functionality and survivability in contested environments.

Additive manufacturing constructs three-dimensional objects directly from a digital file. The process begins by digitally slicing the 3D model into numerous thin, horizontal cross-sections. Following these sliced instructions, the 3D printer builds the object layer by layer from the bottom up. This involves extruding melted material like plastic filament and selectively curing liquid photopolymer resin with light.

Soldiers can rapidly produce replacement parts for damaged drones, fabricate specialized tools and fixtures for maintenance at the battalion level, and even create custom adapters or mounts for unique mission requirements directly in the field, significantly saving Soldiers' time and the division's maintenance costs.

Such advancements in operational readiness and flexibility through AM directly support the framework established by the Ivy Division's priorities.

Integrating the Ivy Division Priorities

Two of the division’s priorities — lethal teams and peak partners — play a significant role in sUAS and AM.

Ferris said AM empowers the 4ID to translate urgent operational needs into tangible solutions for sUAS quickly. AM enables the rapid design and fabrication of prototype sUAS or specialized components to address specific battlefield challenges.

Ferris said that units such as the 4CAB's Dragonflies and the 10th Special Forces Group have made significant strides in integrating sUAS into training, ensuring that 4ID remains prepared for the challenges of modern warfare.

These technologies directly enhance the priorities of lethal teams by equipping Soldiers with superior situational awareness with sUAS reconnaissance and surveillance. Additive Manufacturing ensures these critical eyes-in-the-sky and other essential gear can be rapidly repaired and maintained even in austere environments, keeping teams equipped, informed and deadly.

To maintain this technological edge and ensure a future of skilled personnel, the 4th Infantry Division actively engages with the local community, especially in STEM education.

Keri Brandt, 4ID’s Ivy Human Capital Campaign manager, said the division's collaboration with District 8 highlights its well-established connections within the wider Front Range community. Brandt explained that a significant part of their partnership development strategy includes a mentorship program for students in science, technology, engineering and mathematics. This program brings students to the military installation for on-site visits, allowing them to see directly how the 4ID applies coding, engineering, and technological principles in the operation of drone and robotics systems. Brandt explains that 4ID and Fort Carson service members participate in district events to help facilitate STEM competitions, fostering student engagement and learning opportunities.

The future holds significant promise for integrating AM and sUAS. Empowering units like the sUAS Innovation Platoon with organic manufacturing capabilities and integrating artificial intelligence and machine learning could lead to automated design optimization for battlefield repairs.

Ultimately, the potential for Soldier-level customization and repair of sUAS using user-friendly AM systems could revolutionize battlefield logistics and operational flexibility.

As AM and sUAS technology continues to mature and integrate with other advancements, its role in empowering the Ivy Division and the broader military with cutting-edge aerial capabilities will continue to grow, ensuring a decisive edge in future conflicts.

Social Sharing