Remove multiple forward support companies (FSCs) from their respective infantry battalions, consolidate them under a single company, and task that company with sustaining and managing support for the multiple infantry battalions within a brigade. This is the mission of the general support company (GSC). Consisting of combat logistics platoons (CLPs), combat repair teams (CRTs), and field feeding sections, the GSC is a leaner, more flexible solution designed to meet the logistical needs of infantry units with greater agility and access, providing more forward sustainment than has been provided by legacy sustainment platforms. GSC packages are tailored to specific mission requirements and attached to battalions when needed, providing responsive and adaptable sustainment without the footprint of traditional FSCs.

The transformation to GSCs is primarily driven by the Army’s renewed focus on large-scale combat operations (LSCO), where divisions are expected to be the primary unit of action. Headquarters, Department of the Army, Execute Order 138-24 pushed the transformation in contact (TiC) initiative, with the primary line of effort being to drive organizational change. The U.S. Army Combined Arms Support Command’s efforts were nested within TiC and drove the designing of prototype structural changes to accelerate organizational, material, and doctrinal innovation. These new brigade combat team designs needed to be lighter and more mobile, and to create a smaller sustainment footprint.

One of the infantry brigade combat teams (IBCTs) selected for TiC was the 2nd IBCT “Warrior Brigade,” 25th Infantry Division (ID). In response to these requirements, the Warrior Brigade has adopted this shift, converting into a prototype light brigade combat team (LBCT). Changes include the reorganization of a cavalry battalion into an infantry battalion, the integration of new equipment (such as infantry squad vehicles and drones), and the establishment of new units such as cross-domain effects companies. Most notably, the shift also entails the conversion of the traditional brigade support battalion into a light support battalion (LSB), which subsumes FSCs into a GSC structure, with CLPs and CRTs providing tailored logistical support.

The transition to the GSC model marks a departure from the FSC structure, which became standard during counterinsurgency (COIN) operations. During the war on terror, the modularity of FSCs proved ideal, allowing battalions to maintain organic sustainment assets tailored to frequent deployments by brigades and smaller units. In LSCO, however, where divisions are the focal point of operations, this localized sustainment structure is less effective. GSCs provide flexibility at the division level to allocate resources as necessary. As the Army shifts its focus from COIN to LSCO, GSCs are emerging as the modern solution to sustain the future divisional warfighting units of action.

The underlying concept of the GSC model is to consolidate sustainment assets previously dispersed among FSCs, enabling the LSB to provide flexible, tailored support. Consolidating personnel and equipment allows the LSB to efficiently scale its resources in response to evolving mission demands, deploying only what is necessary while weighting the brigade commander’s priorities. This approach enables the LSB commander to direct sustainment resources precisely where they are needed through the support operations (SPO) officer.

While FSCs provided battalions with immediate, on-hand sustainment, this convenience sometimes led to inefficiencies. Some units grew accustomed to instant access to resources, and sustainment planning began to shift from battalion staffs onto FSC commanders. As FSC commanders and their units shouldered these responsibilities, other leaders, such as executive officers and S-4s, often became less involved in sustainment planning. The GSC structure rebalances these roles, prompting S-4s and SPO officers to collaboratively manage logistics planning and execution. With sustainment assets centralized, the LSB can now dynamically allocate resources, optimizing the placement and use of logistics elements to avoid the delays and obstacles that sometimes accompany distributed FSC assets. This consolidation of sustainment capabilities enhances the LSB commander’s ability to prioritize and direct resources precisely, particularly during high-demand periods or critical points of need.

The flexibility of the GSC structure was demonstrated during the last Joint Pacific Multinational Readiness Center (JPMRC) exercise. The GSC effectively sustained three infantry battalions, accomplishing all that three traditional FSCs would accomplish, but with fewer Soldiers, less equipment, and reduced logistical resources. This leaner streamlined approach allowed for a more forward-focused sustainment effort. The GSC’s versatility was further evident when it supported not only its assigned infantry battalions but also various enablers, including a fourth element that provided comprehensive sustainment (covering all classes of supply and field feeding) to the Japanese Defense Force, Marine Corps, and security force assistance brigade attachments.

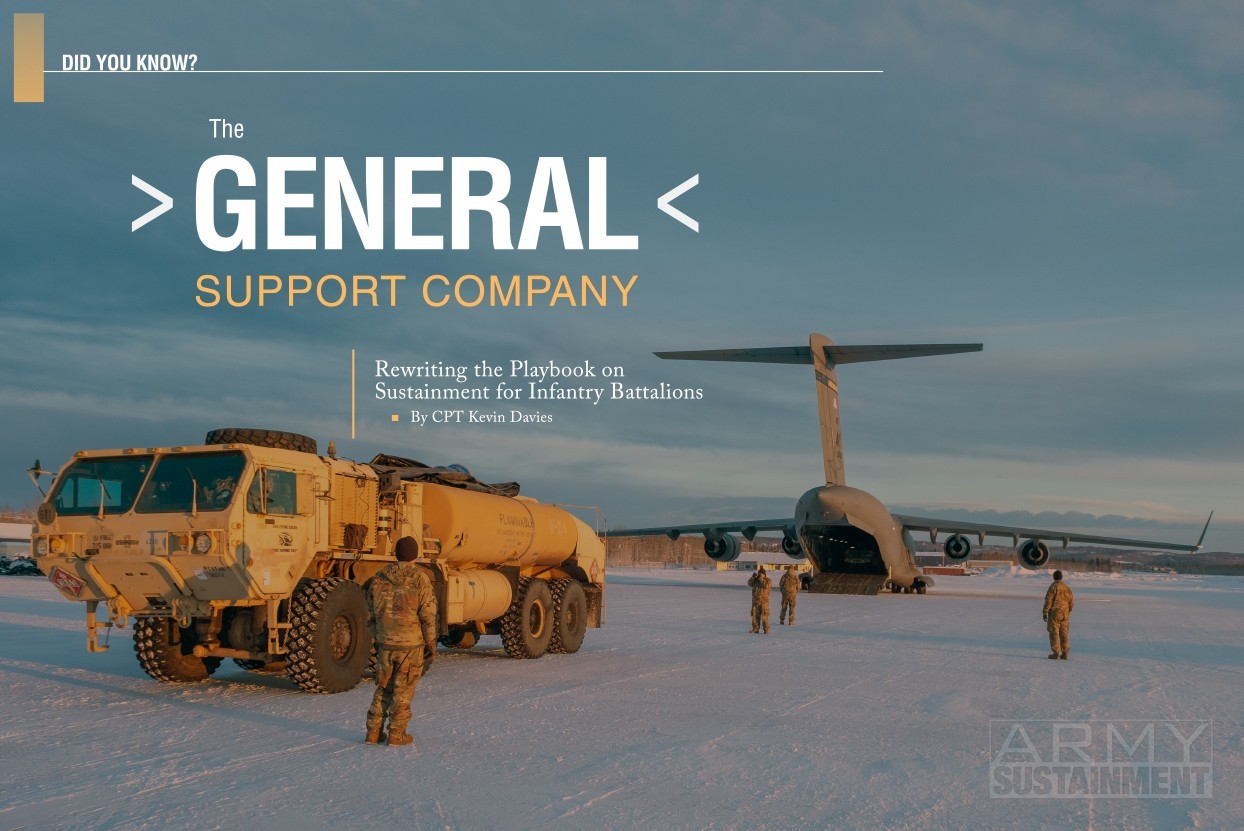

Additionally, the GSC demonstrated its adaptability by cross-leveling equipment to create a lightweight package suitable for airlift to Pohakuloa Training Area in support of the 1st Battalion, 27th Infantry Regiment “Wolfhounds.” Such achievements would not have been feasible if sustainment assets were fragmented among individual battalions rather than unified under one company. Under the traditional structure, the light assets that were necessary to support Task Force (TF) Wolfhound would have belonged to each FSC and would have required sacrifice and cooperation across these battalions to support another’s mission over their own. Because of the terrain and airlift requirements, the legacy sustainment platforms (load-handling systems, tank rack modules, water tank racks, etc.) could not have penetrated the jungle terrain and adequately supported the Wolfhounds’ maneuver. To support this, numerous light medium tactical vehicles (LMTVs), Humvees, water pod systems, and water buffalos had to be collected and traded among the three CLPs.

This flexibility allowed for all battalions to sustain their maneuver. In the GSC structure, analysis was conducted by the SPO officer, missions were prioritized, and equipment was allocated from one company rather than across three or more companies from three or more battalions.

During the JPMRC exercise, the GSC conducted resupply operations via aerial delivery, sling loads, caches, logistics release points, supply points, throughput, and unit distribution, ensuring uninterrupted momentum for all supported TFs. Feedback from the infantry battalion commanders affirmed that sustainment met mission demands without disruption and was a non-issue. This is the gold standard for any sustainment organization during such an exercise.

“Based on the mission sets and threats in COIN, most maneuver battalions were able to rely largely on their FSCs to conduct all types of sustainment operations without much regard to protection and survivability. And battalion commanders grew accustomed to owning most, if not all, the logistics equipment and personnel they would need to conduct these operations internally without much outside assistance. Therefore, these FSC footprints grew larger and larger. In the current LSCO fight, as proven during our JPMRC exercise, protection is paramount. The CLP and CRT provide a much smaller package that is more streamlined, mobile, and responsive for the LSCO fight. I believe this is the best way to protect your sustainment assets and keep them in the fight.”

– LTC Adam F. McCombs, commander, TF Rattlesnake, 2nd LBCT (Prototype), 25th ID

My company, Nightmare Company, as our team is known, was tasked with a daunting problem set: standing up the first GSC and making it capable of supporting three infantry battalions. This mission, though incredibly ambitious, was achieved through extensive collaboration and innovation at every level of the organization.

The company’s structure included a headquarters section, three CLPs equipped with distribution assets, three field feeding sections, and CRTs that were consolidated under the Bravo maintenance company and attached based on the infantry battalion’s requirements. To foster integration, CLP platoon leaders attended infantry battalion planning meetings and coordinated closely with each battalion’s S-4 on sustainment requirements.

As the GSC commander, I worked closely with the SPO officer to allocate assets and resources effectively, balancing them across time and space. I prioritized planning, personnel, readiness, supply, and training, taking on most meetings, administrative requirements, and coordination efforts, freeing up the CLP platoon leaders to focus solely on informing sustainment requirements and execution.

Consolidating all field feeding resources improved personnel management, equipment maintenance, speed, and flexibility. Supporting an LBCT, Nightmare Company shifted focus from the expansive containerized kitchens to more mobile assault kitchens. Designed to serve up to 250 Soldiers per meal, the assault kitchens have consistently supported over 450 personnel per meal across four battalions, enablers, and internal base clusters within the LSB.

We achieved this by leveraging distribution assets within the CLPs, along with additional field feeding equipment and training operators to deploy efficiently — even at night. The addition of field feeding assets also enabled our CLPs to strategically allocate lighter equipment (Humvees, LMTVs, water pod systems, water buffalos, etc.) for forward operations, while heavier legacy sustainment equipment (load-handling systems, water tank racks, forklifts, shop vans, wreckers, etc.) was used in rear positions. This flexible allocation allowed the lighter packages to penetrate more deeply into Hawaii’s jungle terrain, while the heavier assets absorbed any supply chain disruptions from the rear.

Maintenance efforts have also been streamlined through this consolidation. CRTs, which now fall under the Bravo maintenance company within the LSB, become operational control to infantry battalions during war or training events as needed under the CLPs. This arrangement consolidates maintenance resources in the rear while allowing us to surge needed equipment forward, minimizing downtime and the operational footprint. Excess CRT equipment and personnel, when not forecasted to be a mission requirement, are available to assist with internal and pass-back maintenance within the LSB and to bolster defense capabilities.

The success of this model is due to strong collaboration between infantry battalion S-4s, company executive officers, the GSC commander, and CLP platoon leaders, with SPO staff overseeing the big picture. SPO planning efforts have increased and now include recurring logistics synchronization meetings to ensure all units are aligned and operating efficiently. While we have seen considerable gains, there remains room to grow. We are continually refining personnel and equipment configurations to further enhance Nightmare Company’s capabilities and, by extension, those of future GSCs.

In today’s rapidly evolving operational landscape, the GSC model offers a glimpse into the future of Army sustainment. It balances efficiency with flexibility, empowering leaders to direct logistical resources with precision and adaptability while keeping the force undetectable, agile, and responsive on the battlefield. The GSC represents a significant shift in sustainment that aligns with the Army’s vision for LSCO, enabling efficient, scalable, and mission-focused support across dynamic operational environments.

--------------------

CPT Kevin Davies currently serves as the first commander of the Army’s first general support company, 225th Light Support Battalion (LSB), 2nd Light Brigade Combat Team, 25th Infantry Division (ID). His previous assignments include support operations transportation officer in charge, Headquarters and Headquarters Company, 225th LSB; S-3 operations officer for the 87th Division Sustainment Support Battalion, 3rd Sustainment Brigade, 3rd ID; and executive officer for the 135th Quartermaster Company, 87th Division Sustainment Support Battalion. Before joining the Army, he was a Marine infantryman in the 1st Marine Division. He has deployed throughout U.S. Central Command and U.S. Indo-Pacific Command. He holds a Bachelor of Science degree in supply chain management from Arizona State University.

--------------------

This article was published in the spring 2025 issue of Army Sustainment.

RELATED LINKS

The Current issue of Army Sustainment in pdf format

Current Army Sustainment Online Articles

Connect with Army Sustainment on LinkedIn

Connect with Army Sustainment on Facebook

---------------------------------------------------------------------------------------------------------------

Social Sharing