ABERDEEN PROVING GROUND, Md. (April 13, 2015) -- Despite the drawdown of American Soldiers in Afghanistan, the U.S. Army engineering community is continuing to develop rapid technological solutions.

The U.S. Army Rapid Equipping Force, or REF, and U.S. Army Research, Development and Engineering Command, or RDECOM, have partnered to maintain this support on Bagram Airfield.

By using the REF's Expeditionary Lab, also known as the Ex Lab, the Army has the capability to engineer, prototype and occasionally manufacture items to meet urgent Soldier needs.

"The REF already had fixed lab sites downrange, but in 2011, it containerized a workshop for greater mobility," REF Director Col. Steven Sliwa said. "Over the years, this has allowed more deployed units to access the lab, its forward fabrication capability and, most importantly, the problem-solving capability of the Ex Lab team. With the Ex Lab tool, we are collaborating as far forward as possible, resulting in more innovative solutions."

The Ex Lab's staff consists of a REF non-commissioned officer, or NCO, in charge, a government civilian lead engineer and two contractors - an engineer and a technician. In October 2014, RDECOM began providing the Ex Lab's lead engineer.

"The partnership with RDECOM and the engineering team at the command's Edgewood Chemical Biological Center [ECBC] to staff the REF Expeditionary Labs has been great," Sliwa said. "I see it as a win in multiple columns - ours, RDECOM's and the deployed unit's. The labs present engineers with constantly evolving challenges, and I believe that the ECBC engineers' experience and expertise elevates the solutions we create for Soldiers."

RDECOM encompasses seven research and engineering centers throughout the United States that touch nearly every aspect of Army technology and equipment.

Jason Adamek, an ECBC mechanical engineer, serves as the primary lead for coordinating RDECOM's reachback support to the lab.

"It's a natural fit for the type of expertise that exists in RDECOM to support the REF Ex Lab, which does a wide variety of projects," Adamek said.

"Anything that comes through the lab's door, they'll try to support. If the lab can't accomplish the task, the lead engineer can reach back into a much greater, broader network of subject matter experts within RDECOM."

Before the Ex Lab team reaches back to the RDECOM support, it identifies and refines Soldiers' challenges. The Ex Lab non-commissioned officer in charge meets with Soldiers in theater to gain a first-hand understanding of the challenges and operational capability shortfalls units are facing.

Angel Cruz, also an ECBC mechanical engineer, was the first lead engineer after the RDECOM/REF partnership began.

"The primary role of the NCO is to be the voice to the Soldiers, and he typically brings the government engineer with him," Cruz said. "They circulate the battlefield, meeting with the units, and seeing what capability shortcomings they currently have. The engineer might be able to offer advice or develop a design with the user."

Sgt. 1st Class Justin Fulk, the Ex Lab non-commissioned officer in charge, said bringing the experts directly to units is vital.

"The ability to bring the engineer to the units on the ground is what sets the REF apart," Fulk said. "We are able to witness capability gaps first hand, solve problems where they exist, and put the Solider back in the fight quickly by providing simple solutions on site.

"Additionally, we have the ability to take more complex solutions back to the lab for further analysis. We can run the solution through computer simulations, reach back to engineers or academia in the U.S. and produce several iterations of prototypes until we get the solution right."

The staff's ability to complete multiple design iterations in theater is a significant benefit, Cruz said.

"With design, iterations are important. Engineers rarely get it right on the first try. By being able to build various iterations of a new design in country versus shipping them from the United States, you're saving a lot of time," he said.

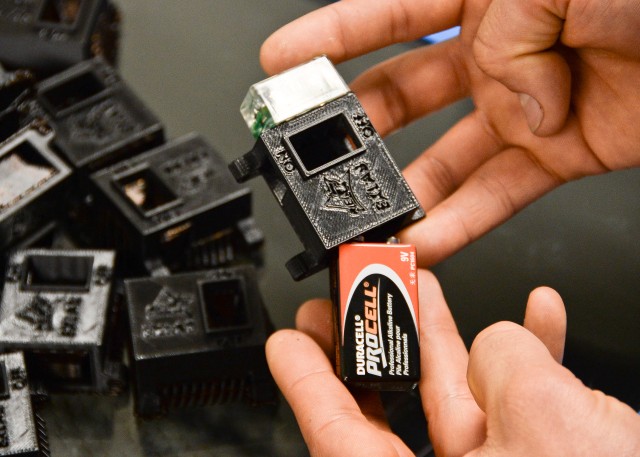

To demonstrate how the elements of the lab come together, Cruz described a Ex Lab project to improve the infrared beacons issued to Soldiers for identification, recovery or marking sites.

"To turn it on and off, you have to plug and unplug the battery from the beacon. It's two pieces that can get separated and lost. It requires you to use both your hands, and you have no way to mount it to anything," he said.

In response to these shortfalls, Soldiers approached the Ex Lab to design an adapter for the IR beacon that included an on-and-off switch, provided mounting tabs and enabled quick, one-finger operation. The lab went through several design iterations driven by the requesting unit's feedback.

Once the unit was satisfied with the design, the lab began building the adapters on-site. They then e-mailed the adapter's computer-aided design file to the ECBC Advanced Design and Manufacturing Division on Aberdeen Proving Ground, Md.

ECBC used one of its large 3-D printers to make additional adapters and send them forward so that the Ex Lab's printer would not be tied up for days making the same part.

"If they're making a bunch of the same parts up to their capacity, we can do that here," Adamek said. "We can manufacture parts faster and more efficiently here and send them forward.

"We try to keep the lab away from the churning out of parts and instead focusing on design and problem solving."

Sliwa praised the collaboration.

"The relationship between REF and ECBC is a prime example of Army partnering done right. We are able to reach back to all the Army's labs for additional support on our toughest challenges. When a Soldier comes to the REF Ex Lab, they are coming to the entire Army problem-solving community," he said.

-----

Currently the Ex Lab is stationed at Bagram Airfield. Deployed units with operational challenges should contact the Rapid Equipping Force Operations Center at usarmy.belvoir.hqda.mbx.ref-ops-center@mail.mil or on its website at www.ref.army.mil.

RDECOM is a major subordinate command of the U.S. Army Materiel Command. AMC is the Army's premier provider of materiel readiness -- technology, acquisition support, materiel development, logistics power projection, and sustainment -- to the total force, across the spectrum of joint military operations. If a Soldier shoots it, drives it, flies it, wears it, eats it or communicates with it, AMC provides it.

Related Links:

Army.mil: Science and Technology News

U.S. Army Research, Development and Engineering Command

Social Sharing