WASHINGTON (Army News Service, May 22, 2014) -- A thicker barrel will absorb more heat in the new M4-A1 carbine, should a Soldier need to flip the selector to auto, according to Soldiers overseeing the new configuration now being added to the M4.

While shooting in the automatic mode is less efficient and not as accurate as firing in bursts, it has its place on the battlefield, explained Command Sgt. Maj. Doug Maddi, Program Executive Office Soldier, Fort Belvoir, Va.

"Soldiers need automatic capability while providing suppression fires during fire and movement," he said, noting that Soldiers deployed to Afghanistan asked for that and are now getting it, an option absent in the M4, which only fired in semi-automatic and bursts. A new drop-in trigger allows the A1 to function with the automatic setting.

Maddi and others spoke May 21, during a media roundtable, marking the milestone of the first Army unit to receive the beefed-up carbines, 1st Infantry Division, out of Fort Riley, Kan.

The beefier weapon is not unknown to the Army. Soldiers in U.S. Special Operations Command have been using M4-A1s since 1994.

The tradeoff in weight and performance is something Soldiers gladly accept, Maddi said, noting that the M4-A1 weighs 7.74 pounds, compared to the M-4's 7.46. The weight comparisons include the back-up iron sight, forward pistol grip, empty magazine and sling.

Another feature that's new on the A1 is an ambidextrous selector lever, something that's especially attractive to Maddi, who said he's a lefty who often gets left out when it comes to equipment design.

Doing the numbers, Lt. Col. Shawn P. Lucas, product manager Individual Weapons, Picatinny Arsenal, N.J., said the configuration conversion won't be finished until the half-millionth carbine is converted, by the end of 2019.

Priority for those receiving the A1s will obviously go to brigade combat teams that are high in the readiness cycle and likely to deploy, said Lucas, adding that Army headquarters and U.S. Army Forces Command use a readiness model with a lot of variables that are periodically adjusted, so providing a schedule of which units will get A1s and when, would be guesswork at this point.

Total program cost, including all the labor and hardware, is an estimated $120 million, he said.

Right now, conversions at Fort Riley are starting to get ramped up, with about 300 conversions being done a day, Maddi said. That works out to an entire brigade combat team getting A1s every week or so. And, those who are getting them are offering "resounding accolades."

Maddi said 2nd Brigade is receiving the new configuration even as one of their battalions is deployed conducting gunnery exercises. "Good units are able to do multiple things at multiple times, and I appreciate that."

CONVERSION PROCESS

The Maneuver Center of Excellence at Fort Benning, Ga., requested implementation of the conversion, in 2010. Reliability testing for the A1s was done at Aberdeen Proving Ground, Md., in 2013, to ensure "no harm" to performance following the conversion. After successful testing, Army headquarters gave the nod to begin the conversions, Lucas said.

Anniston Army Depot, Ala., then began receiving parts from large firms like Colt and from a number of small businesses. A team from U.S. Army Tank-Automotive and Armaments Command, Warren, Mich., assisted, he added.

The parts were then boxed up and shipped to Fort Riley, much like a dresser might be shipped to a customer with instructions on how to screw it all together.

But unlike a dresser that might come with instructions that are hard to understand, the A1 parts came with highly trained armament technicians to do the conversions, Lucas said.

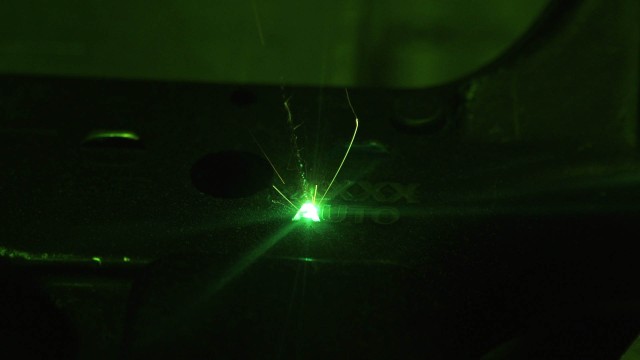

Besides doing the assembly of the upper and lower receiver and bolt carrier group, the team brought along a laser engraver to re-mark the setting nomenclature, he said. "Safe, Semi and Burst" was changed to "Safe, Semi and Auto." Also, the "A1" was added to "M4."

The A1 conversions will probably not be the last word on the carbine, said Maddi, who expects it to continually evolve.

Every Soldier qualifies with the carbine, or the M16-A2 or M16-A4, twice a year. Their feedback, along with that of Soldiers returning from theater, will continue to be monitored and tweaks to the system are always possible, he said.

The small-arms community -- which includes Soldiers, special operators and those from the other services -- are discussing other performance enhancements like an extended forward rail, folding front sight post, match-grade triggers for designated marksmen, and integration of suppressors, he said, adding that at this time they're only "on the drawing board."

Maddi thinks Eugene Stoner, the designer of the M16 and its family of weapons, including the carbine, should be considered in the same august group as Colt, Smith & Wesson and Browning.

The M4, which Stoner designed several decades ago, was "a pretty good idea," Maddi said.

"Soldiers trust in it" and it consistently ranks first among all weapons in Soldier satisfaction surveys, he added.

So, he said, "the big question is, 'how do you improve on something that's already pretty darn good?'"

(For more ARNEWS stories, visit http://www.army.mil/ARNEWS, or Facebook at www.facebook.com/ArmyNewsService)

Social Sharing