Rock Island Arsenal Joint Manufacturing and Technology Center recently hosted an event that had been more than 20 years in the waiting. Though it was called the Soldier Weapons Readiness Center Ribbon Cutting ceremony, there was no ribbon to be cut. It was more of a celebration-in RIA commander Col. Craig Cotter's words, "a celebration of the reestablishment of a capability here at the Rock Island Arsenal that is absolutely critical to the nation's security."

RIA reintroduced the ability to manufacture small arms repair parts at the brand new, state-of-the art Soldier Weapons Readiness Center. Twenty-three years ago, the arsenal stopped making small arms repair parts for the Army, but now, they are back in business. And with almost 200 people in attendance, the event was big.

"You know, over the course of your career, there's four or five events where you have the opportunity to make a difference," said Jerry Jackson, site manager for TACOM LCMC Rock Island. "I'm here to tell you that reestablishing a small arms parts focus factory here at Rock Island Arsenal is one of those things that I will always remember. We really made a conscious effort to make a big difference in the capability that we provide for our Warfighters."

Built upon LEAN manufacturing and equipped with the latest technology in machinery, the 38,000-square-foot center has already proven the agility it can provide. Just a few months ago, it was able to deliver an emergency order of 1,000 firing pins to the field in just 32 days. An order like this can sometimes take up to eight months to complete.

"We have created a space which allows us to take raw material in the door and take packaged product out the door," said Paul Briggs, General Manager for the SWRC "The efficiencies are plentiful and we are expecting nothing but high quality performance and decreasing turnaround times to meet the urgent Warfighter needs."

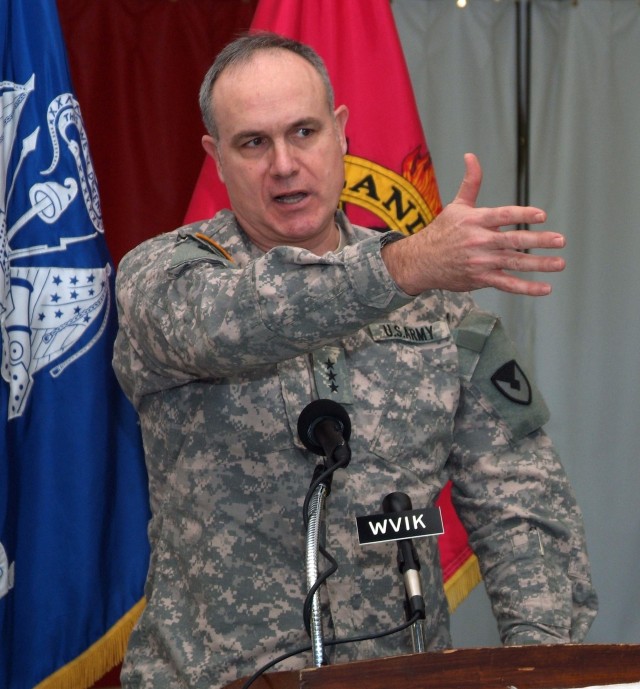

Keynote speaker Lt. Gen. James Pillsbury, deputy commander of Army Materiel Command, sent a message to everyone in the room about the importance of single mindedness of purpose, and sincerely thanked them for what they do.

"This is manufacturing capability is a national treasure," he said. "It must be maintained and improved upon."

The launch of the new center has personal meaning for factory supervisor Chester Fritch.

"I feel like I'm meeting my goal of paying back the debt I owe to the people who worked here in the 60's when I was in Vietnam," said Fritch. "These people were part of the reason I could come home safely. My team and I are here to do the same."

The ceremony ended with a symbolic rifle exchange representing RIA's past meeting its future. A donated original 1903 Springfield rifle that was produced at RIA was presented to Cotter and placed in display at SWRC. In return, Cotter presented a M14 EBR rifle, for which RIA makes parts today, to a representative from the office of Program Manager Soldier Weapons.

The event also marked TACOM Commander Maj. Gen. Kurt Stein's first visit to RIA.

We're excited to be making a contribution to Army's readiness," said Cotter. "At the end of the day, that's why we're here."

Social Sharing