Power Generation, Storage, and Distribution in LSCO

Download the full article here: No. 25-1085, Best Practices on Operationalizing Battlefield Energy (Aug 25) [PDF - 2.2 MB]

Introduction

In the age of drone swarms, sensors, networked command posts, and autonomous systems, energy is no longer just a support requirement, it is a warfighting necessity. And yet, Brigade Combat Teams continue to treat electrical power as a secondary function of logistics, hidden inside the margins of Class III (fuel) or Class VII

(generators) sustainment. As we prepare for large-scale combat operations (LSCO) against peer adversaries, it is time to formally recognize battlefield power as its own domain of sustainment that must be thoroughly planned and synchronized like any other supply commodity.

Just as Class V (ammunition) enables kinetic dominance, battlefield energy must enable electromagnetic and digital dominance across the battlefield. The future fight will not be won solely by the formations that shoot the fastest or move the farthest, but by those that can sustain drones, sensors, command nodes, and autonomous systems with uninterrupted, distributed energy. We must build a logistics network capable of pushing and pulling modular power generation and storage systems across every echelon from squad to corps.

- This paper intends to highlight the best practices and lessons to optimize power generation.

The Problem: Power Is Fragmented and Forgotten

The Army's current approach to battlefield energy is fragmented, under-theorized, and operationally vulnerable. Units rely on a patchwork of Army issue and commercial generators, often oversized, underutilized, and vulnerable to detection. The results are predictable:

- Waste and Overload: As shown in 2/101 MBCT's experiences at Lethal Eagle 24.1, 15- and 30-kilowatt (kW) generators often operate at less than 10% capacity. These inefficient systems require excessive fuel, generate unnecessary heat and audible signatures, and limit mobility due to their bulk.

- Invisibility in the Supply Chain: Generators and lithium-ion energy storage modules are not tracked as operational effects. They lack visibility in sustainment planning tools such as GCSS-Army or JOPES. Power is treated as an afterthought.

- No Scalable Distribution Model: There is no doctrinally recognized system for pushing charged battery banks, solar arrays, or hybrid inverter-generator systems to company outposts, sensor emplacements, or drone recovery teams. Units improvise – poorly – using ad hoc solutions.

In LSCO, such improvisation may result in the loss of lives. A sensor network that loses power becomes a dead node. A command post that goes dark loses tempo. A drone launch team without recharge capability becomes irrelevant after its first sortie.

Field-Proven: Lessons Learned from the 25th Infantry Division’s Hybrid Power Integration

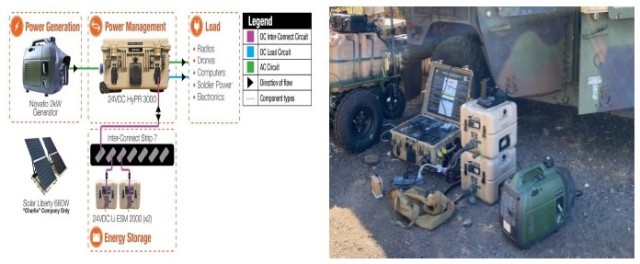

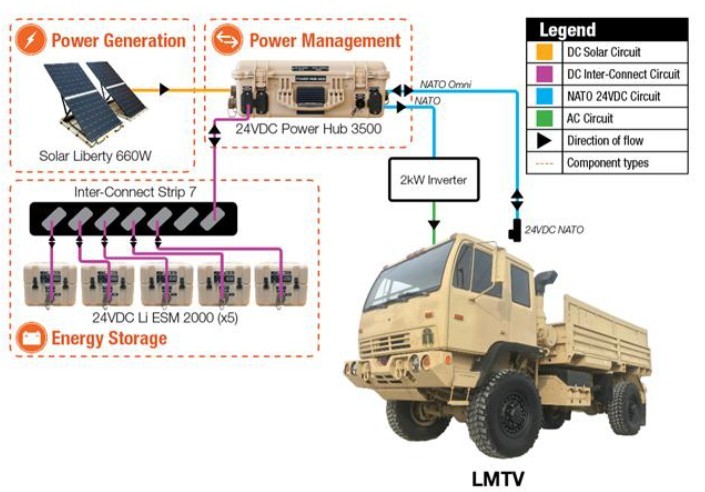

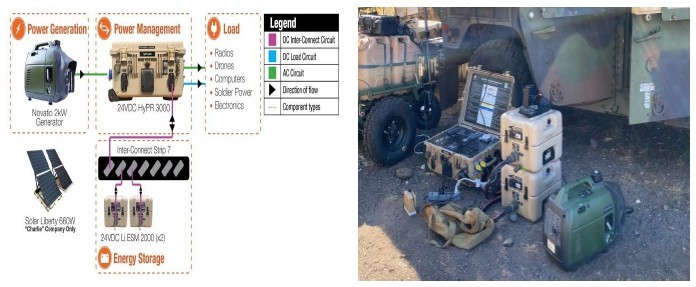

During the 2024 Joint Pacific Multinational Readiness Center (JPMRC) rotation, the 2d Mobile Brigade Combat Team, 25th Infantry Division executed a brigade-sized experiment in contested logistics with a focus on hybrid power. Across multiple battalions and command posts, 2/25ID deployed modular Energy Storage Modules (ESMs), inverter systems, and solar arrays under realistic field conditions to assess the feasibility of battlefield energy sustainment.

The results validated the need for a battlefield energy concept of support:

- Silent Operations: Insertion teams operated for 56 to 96 hours using a single Energy Storage Module (ESM) and a Power Distribution Module (PDM), without relying on generators or vehicles. This enabled continuous use of radios, drones, and mission-critical electronics in remote locations while maintaining a low signature—no noise, no heat, and no movement required for resupply.

- Improved Generator Utilization: Battalion Tactical Operations Centers (TOCs) paired their 30kW generators with modular battery systems to store power during limited run-times. Instead of running continuously, generators operated just 6 hours per day, reducing fuel consumption, limiting thermal/acoustic exposure, and increasing overall efficiency by operating closer to optimal load capacity.

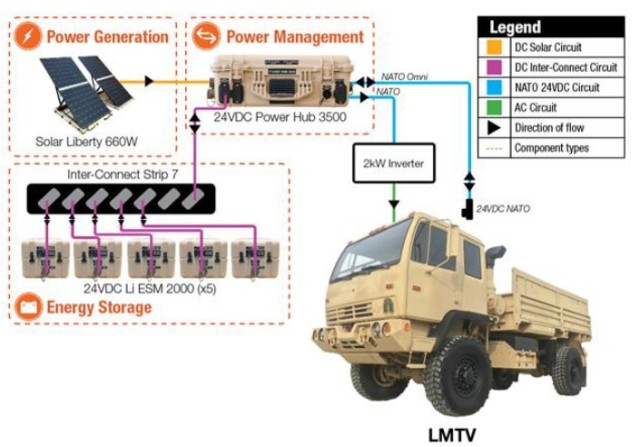

- Vehicle-Based Power Recharging: Units integrated ESMs directly with vehicle electrical systems using standard NATO connectors. Power was harvested from alternators during normal vehicle operations, allowing batteries to recharge without damaging starter batteries. This provided a reliable power source for TOCs and sensors without the need for additional generator assets.

- User-Friendly Setup: The hybrid systems used during the exercise were assembled in the field by Soldiers with minimal instruction. Components were modular, color-coded, and designed for “plug-and-play” integration. No specialized training or technical support was required, accelerating fielding and reducing system downtime.

- Extended Operational Reach: Power kits enhanced the endurance and operational reach of small units by reducing reliance on constant fuel-based resupply. Battery modules were rotated between forward teams and headquarters elements, creating a reusable, modular sustainment model like how ammunition and water systems are distributed and recovered.

These real-world applications of modular hybrid systems illustrate the immediate relevance of a streamlined battlefield energy concept of support. More importantly, they underscore the operational risk of treating power generation as a second-order sustainment task. In a contested theater, the ability to rotate batteries, power management, and redundant energy sources through the sustainment trains just like ammo or water proved decisive.

The Concept: Battlefield Energy Concept of Support Best Practices

To meet this challenge, we must treat battlefield energy on equal terms with the ‘normal’ classes of supply. Battlefield energy would encompass the following categories:

- Modular Battery Packs: Rechargeable lithium-ion or solid-state batteries (e.g., 1–10 kWh) that can be rotated across the battlefield like ammo cans.

- Portable Solar Arrays: Collapsible, soldier-portable panels (e.g., 100–600 W) to augment power at remote sites.

- Hybrid Inverter Systems: Systems like Senergy Power Solutions (formerly Solar Stik) HyPR series, which blend generator, battery, and renewable power inputs to maximize efficiency and reduce logistics.

- Power Distribution Kits: Tactical power boxes capable of splitting, regulating, and directing power to various systems (e.g., drones, radios, server racks).

- Recharge, Recovery, and Refurbishment Nodes: Dedicated power staging points within the Brigade Support Area (BSA), Division Support Area (DSA), and Forward Arming and Refueling Points (FARPs).

Battlefield energy planning functions much like the Army’s water sustainment model. Full water containers are pushed forward to support dispersed operations, while empty containers are returned through the sustainment network to be refilled and reissued. The same principle must apply to battlefield power. Modular battery systems, whether lithium-ion packs, hybrid inverter kits, or power hubs should be issued to patrols, sensor teams, and drone operators at planned rates of use, just like water or ammunition. Once depleted, these power modules must be recovered, recharged, and re-circulated through the distribution system. By mirroring this push-pull model, energy becomes a managed commodity that is tracked, forecasted, and resupplied with the same rigor as any other critical class of supply.

The Model: Modular Energy best practices as a Tactical Commodity

A functioning battlefield energy network would enable “power-on-demand” sustainment through a modular architecture. Consider the following tactical model:

Sustainment Requirements: Best methods to Building the Battlefield Energy Network

To implement a battlefield energy distribution system at scale, the Army must invest in doctrine, structure, and platforms. All battlefield energy sustainment should be centrally managed at the Brigade Support Area (BSA). This activity functions like a Modular Ammunition Transfer Point (MATP) section tracking inventory, staging modular battery systems, recharging spent units, and executing resupply missions based on planned energy consumption across the formation. Company and Battalion Command Posts receive charged Energy Storage Modules (ESMs), and inverter support every 48 to 72 hours, tailored to mission requirements and operational tempo. Spent modules are rotated back through the same distribution channel for recharging and reissue. This push-pull system mirrors the Army’s approach to Class V and water sustainment, enabling persistent power for dispersed operations without forward-positioned generators.

1. Battlefield Energy in the LSB and DSB

Each Light Support Battalion (LSB) and Division Sustainment Support Battalion (DSSB) should include a battlefield energy generation and distribution node within the support area, responsible for:

- Managing inventory of energy storage modules and power management/distribution devices

- Performing charge-rotate-repair functions at BSA/DSA

- Coordinating with S6/SPO planners to forecast power requirements

These nodes could draw from existing 91D (Generator Mechanic) and 94-series specialties, augmented with new training on hybrid and lithium systems.

2. Power Forecasting in Operational Planning

The Brigade SPO and unit S4s at echelon must treat energy as a forecasted sustainment requirement alongside fuel, ammo, and water. Mission analysis must include:

- Estimated kWh/day by unit and task

- Number of modules needed per supply cycle

- Dwell and recharge time

- Emission risk vs operational signature management

This shift demands that commanders and staff treat power as a deliberate sustainment variable during MDMP, aligning energy distribution with maneuver timelines, node placement, and mission-critical systems. Battlefield energy cannot be an afterthought – it must be forecasted, synchronized, and operationalized just like fuel, water, and ammunition.

3. Power Supply Points and Transfer Geometry

To effectively operationalize battlefield energy, the Army must develop a structured power distribution framework modeled after the established systems for ammunition and water distribution. This requires the designation of Power Supply Points (PSPs) at key logistics nodes such as the Brigade Support Area (BSA), Division Support Area (DSA), or Forward Arming and Refueling Points (FARPs) where charged Energy Storage Modules (ESMs), inverters, and hybrid power kits are staged, tracked, and rotated.

Downtrace from these hubs, Power Supply Transfer Points (PSTPs) must be established at battalion-level trains (CTCP, FTCP) down to the company logistics release point (LRP). These locations serve as the tactical handoff points where charged power modules are issued to maneuver units and spent modules are recovered for return to the PSP. The geometry must support continuous, two-way power movement mirroring how full and empty water containers or ammunition loads are pushed and pulled across the battlefield.

Without this echeloned structure of PSPs and PSTPs, power distribution will remain ad hoc, reactive, and vulnerable to disruption. By anchoring battlefield energy logistics to defined geographic nodes, units can ensure modular energy is delivered and recovered at the right time, in the right place, with the same rigor and predictability as fuel or munitions.

Operational Impact: Energy as Combat Power

The introduction of battlefield energy as a managed commodity is not just a logistics reform, it is a force multiplier. Its operational benefits include:

- Signature Reduction: Replacing legacy generators with battery-inverter systems reduces thermal and acoustic detection risks.

- Mobility and Dispersion: Lightweight modular systems enable sustainment of distributed operations, especially in jungle, urban, and mountainous terrain.

- System Uptime: Persistent drone, sensor, and comms functionality especially critical in multi-domain operations relies on uninterrupted power.

- Reduced Fuel Dependence: Less fuel consumption shrinks LOGPAC resupply requirements, enabling smaller, faster, and safer logistics packages.

- Opened Power Architecture: Eliminates dependency on a singular power generation source through the hybrid power systems’ ability to harvest power from numerous resources (generator, vehicle, renewable, etc.).

Conclusion: If You Can’t Charge It, You Can’t Fight with It

The character of warfare is evolving. Future conflicts will be shaped not just by bullets, fuel, and food, but by the ability to power networks of sensors, drones, command posts, and autonomous systems across dispersed terrain. The battlefield is shifting from linear engagements to distributed nodes – and with it comes the need to sustain not just firepower, but electrical power. Battlefield energy is an essential step forward. Just as the Army standardized Class VIII for medical supplies and Class IX for repair parts, it now has the opportunity to designate modular energy as a distinct and intentional commodity, requiring dedicated systems for storage, rotation, maintenance, and distribution.

This is not a distant aspiration, it is a transformation already underway. Exercises like JPMRC have proven that modular power sustainment is not only feasible, but operationally decisive. If a drone can kill a tank, then the battery that powers it must be treated with the same logistical priority as a Javelin missile. The Army is taking the right steps to get ahead of the problem and battlefield energy will be the framework that powers the next fight.

Social Sharing