A DIME FOR A CAROUSEL RIDE - DEVCOM CBC electrical engineer James Severtsen demonstrates how the DIMES are inserted into the carousel attachment on the FLIR Skyraider quadcopter. The quadcopter can then remotely drop the expendable microsensors to create a larger system of DIMES that work together to alert warfighters of nearby threats. (Photo by Ellie White, DEVCOM CBC)

The best chemical agent protection is knowing where not to go.

The best way to keep warfighters safe from chemical agents on the battlefield is to know whether an agent is present before they enter the area. That requires a new kind of sensor, one that can be placed on the battlefield in quantity ahead of time by drones or unmanned ground vehicles (UGVs) to form a meshed network that communicates back to command and control.

The U.S. Army Combat Capabilities Development Command Chemical Biological Center (DEVCOM CBC) found a new approach to acquisition to get this entirely novel approach to sensing fielded faster than the traditional acquisition cycle allows. To do this, the technology development team at the center changed the acquisition paradigm by shaping the requirements to best take advantage of an emerging technology, rather than develop technology-agnostic requirements and request bids from vendors.

IDENTIFYING THE POSSIBLE

The initial challenge was posed by the Defense Threat Reduction Agency’s Joint Science and Technology Office (DTRA JSTO) in 2019: “Was it possible to develop Chemical, Biological, Radiological and Nuclear (CBRN) sensors that could be smaller and expendable?” DEVCOM CBC Senior Research Chemist Alan Samuels, Ph.D., took up the challenge and developed a draft of his Leave In-Place Chemical Sensor (LIPCS) concept. The idea was shared with the chemical biological defense community, which included a key member, the U.S. Army Maneuver Support Center of Excellence’s Capabilities Development and Integration Directorate (MSCoE CDID) at Fort Leonard Wood, Missouri. They saw the value of the concept for warfighter early warning.

DEVCOM CBC Senior Research Scientist Patricia McDaniel, Ph.D., arrived at the Center in 2020 from a Navy office that specializes in rapid research and development. She was looking for a technology initiative that would make a real contribution to warfighter protection. She immediately saw the potential of LIPCS but needed a tiger team to take on the challenge of operationalizing the concept.

FINDING ACE-IN-THE-HOLE RESEARCH PARTNERS

In 2021, using Center investments, McDaniel devised a strategy to begin maturing the concept of an inexpensive, attritable family of sensors operated on battery power and capable of detecting chemical agents before warfighters enter an area. She reached out to DTRA JSTO, the original initiator of LIPCS, and persuaded them to partner with the Center in advancing the effort. McDaniel then assembled a research team composed of scientists and engineers from across the Center to tackle the problem using a wide range of technical expertise within a single research Center.

The concept needed to be fleshed out before the team could effectively develop prototypes, so the Center assembled an interdisciplinary team of scientists and engineers to conceptualize a miniaturized microsensor and identify what was within the “realm of the possible.” This interdisciplinary team followed a methodology for innovation the Center created in 2019, called the Warfighter Innovation Leveraging Expertise and Experimentation (WILE-E). In 2022, the WILE-E team began by using the microsensors initiative’s problem statements to break the research and development effort into manageable pieces to be addressed over six-month, two-year and ten-year timeframes.

In the fall of 2022, the team turned to another partner, the U.S. Special Operations Command (SOCOM), for help finding technology developers to manufacture the sensor prototype. The Center had worked previously with SOCOM to establish an innovation incubator known as the Accelerator for Innovative Minds (AIM). DEVCOM CBC was able to use AIM as a mechanism for fast-track collaborations with vendors for sensor development.

AIM released a request for technology applications in the form of problem statements to be answered. The problem statements addressed challenge areas in the categories of “sensor,” “micro” and “deployable.” More than 40 small businesses, laboratories and universities responded to this request. After reviewing the responses in early 2023, the team identified three sensor development companies to work on improving sensor technology and three sensor delivery platform developers to work with the sensor companies to build an integrated delivery vehicle.

An important partner in the WILE-E initiative was Design West Technologies, Inc. (DWT) of Tustin, California. Members of the WILE-E team knew that DWT had developed the novel “DropPuck” system for delivering material and decided that it was a promising platform for experimentation and demonstration with sensors. It can fly over an area and drop hockey puck-shaped sensors onto the ground in a designated pattern. The miniaturized sensors communicate in tandem through a wireless MESH network, enabling the system to communicate in the field by way of their proprietary command-and-control end-user devices. In early 2023, the WILE-E team held a field demonstration at Aberdeen Proving Ground, Maryland, to demonstrate the microsensor concept. The DropPuck system was integrated onto a Forward-Looking Infrared (FLIR) Skyraider quadcopter by the Center’s Engineering Directorate. Personnel from the MSCoE CDID attended the event and provided practical feedback from the warfighter’s point of view.

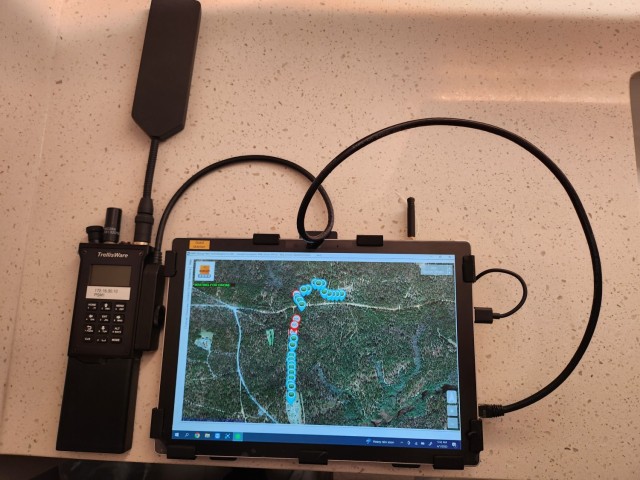

A VIRTUAL VIEW - A MESH network device displays a virtual view of the puck array deposited by a quadcopter at the Army Expeditionary Warrior Experiments annual event at the Maneuver Support Center of Excellence at Fort Leonard Wood, Missouri, in March 2023. (Photo by U.S. Army)

In March 2023, DEVCOM CBC, again in partnership with DWT, executed a field experiment at Army Expeditionary Warrior Experiment 2023, an event that the MSCoE CDID hosts annually to test tactical concepts and capabilities in support of multidomain operations. The event was attended by a broad range of warfighters and yielded valuable end-user and expert assessor feedback on the concept’s current strengths and on areas in need of further development.

BRINGING THE PIECES TOGETHER

To carry out field expeditionary experiments with Soldiers and rapidly adapt the system to address their feedback, DEVCOM CBC’s Engineering Directorate designed and fabricated a modular microsensor demonstration prototype called the Deployable Integrated Microsensor Evaluation System (DIMES). It is a series of playing card-sized packages, each one housing a commercial volatile organic compound sensing element, communications chip and power source. These sensing elements are a placeholder for future chemical agent-specific sensing technologies under development by the joint DEVCOM CBC-JSTO effort. These individual DIMES are then placed inside a circular dispenser called the carousel, so-called because it resembles an old-fashioned slide carousel. The Engineering Directorate designed the carousel to be integrated with either a quadruped robotic system, called Spot, that the technology developer, Boston Dynamics, designed, or on an aerial platform such as the FLIR Skyraider using a standardized DEVCOM CBC-developed interface.

SHAPE SHIFTING - DIMES has gone through many iterations. The design shifted from being cylindrical (as shown on the right) to rectangular (as shown on the left) to maximize space efficiency and increase the surface area of the printed circuit board. (Photo by Ellie White, DEVCOM CBC)

The Deployable Microsensor Initiative initially focused on the technical advances of chemical sensors. However, before the team could take advantage of the low size, decreased weight and reduced power (SWaP) needs of a new generation of sensors, they had to solve the problem of inconsistent methodologies for evaluating sensor performance. That meant they had to continuously scan sensor development progress across academic, government and industry laboratories to find the best candidates to assess for feasibility. It also required them to develop standardized methodology that consistently assessed a variety of sensor technologies as the sensors continued to be improved. The team drew upon expertise within the Center to develop sensor evaluation protocols to assess and then compare sensor results and development progress.

SEE SPOT DEPLOY - The UGV, Spot, carries the carousel designed to contain deployable sensors. The carousel attachment is compatible with multiple remotely operated delivery vehicles. (Photo by Ellie White, DEVCOM CBC)

That was just the first part of what quickly became a multi-tiered effort. The team not only had to find the best way to identify and validate high-quality, low-SWaP sensor technologies; once the sensors were distributed and engaged in detection, they had to be able to send the detection data through a battlefield communications network so warfighters on the ground and their commanders would be alerted to threats in near real-time.

The DEVCOM CBC Engineering Directorate had the capability to rapidly construct advanced microsensor demonstrator prototypes and integrate them with a variety of delivery vehicles and communication networks. That way, the team could quickly see the strengths and weaknesses of each using warfighter feedback.

TAKING TO THE FIELD

Meanwhile, MSCoE CDID took lessons learned from the demonstrations and experiments to draft an Army Capability Development Document (CDD) that specifies the operational benefit that the technology provides. The CDD progressed from MSCoE CDID through Future Capabilities Command to Army Futures Command, where the validated concept was submitted to the Assistant Secretary of the Army for Acquisition, Logistics and Technology (ASA(ALT)). In August 2023, ASA(ALT) sent the Joint Program Executive Office for Chemical, Biological, Radiological and Nuclear Defense a letter designating it as the Office of Primary Responsibility for the maturation and acquisition of this technology. This designation moved the Deployable Microsensor System further down the acquisition cycle to becoming a recognized Program of Record.

By April 2024, the pace of the Microsensors program quickened further. The concept demonstrator was put through its paces in a series of field exercises starting with DTRA JSTO’s Rio Robotico, a venue that allows technology developers an opportunity to operate autonomous vehicles outdoors in a variety of scenarios. At this event, prototype sensor systems were distributed in a variety of terrains in the West Texas desert, where sensor range, data throughput and overall communication was assessed.

The next stop was DTRA JSTO’s Tenacious Dragon 2 (TD2) experimentation at Joint Base San Antonio-Camp Bullis, Texas, in July 2024. DIMES showcased its integrated early warning capability during the event. Participating warfighters concluded that DIMES proved itself as a leap forward in remote and wide-area early warning capability.

TD2 was followed by Beholder’s Gaze in fall 2024. This event addresses integrated early warning capability needs in the U.S. Indo-Pacific Command, and the DIMES proved the value of an integrated system of systems for remote monitoring.

The next big test was Project Convergence Capstone 5, the U.S. Army’s marquee technology modernization demonstration event, held at the National Training Center at Fort Irwin, California, in March 2025. The system demonstrated its applicability to two of that year’s major themes: Data-Driven Decision Making and Expanded Maneuver.

CONCLUSION

The conventional Joint Capability Integration Development System approach to defining and validating requirements simply cannot keep pace with the rapidly changing technology landscape and dynamically evolving threats. A better approach is to design experiments to address prioritized capability gaps using the best available technology solution with the warfighters in their operational setting. This drives the refinement of the technical solutions, and the acquisition process adapts through agile development.

Samuels is very pleased with the results of the Microsensors program. “We showed the acquisition community that a new paradigm for getting an advanced technology into the hands of warfighters far faster is possible,” he said. “We were able to demonstrate a technology that keeps the warfighter away from the threat altogether using a system that does not further burden them with more stuff to carry or more operational responsibility.”

McDaniel agreed. “We proved the advantage of a new paradigm where requirements are informed by the science and technology communities using experimentation prior to finalizing the capability documents,” she said. “This has been a cross-government effort involving several organizations, government agencies and private industry, coming together to make rapid development and fielding of a breakthrough concept happen. It was truly a team effort.”

Next steps for the team are to identify the best-of-breed sensing elements and decision analytics for the microsensor and quantify its detection confidence. The team will also continue to investigate and improve the wireless MESH networking architecture and refine and improve the deployment system. Finally, they will work on discovering new concepts for how best to employ this technology.

For more information, go to https://www.cbc.devcom.army.mil.

BRIAN B. FEENEY, PH.D., is a public affairs specialist at the U.S. Army Combat Capabilities Development Command Chemical Biological Center, where he writes news and feature stories on the science and engineering achievements of the Center’s researchers. He has written for the Center since 2014. He holds a Ph.D. in risk communication from Temple University, an M.A. in communications from Cornell University and a B.A. in history from Colorado College.

Follow us @USAASC

Social Sharing