The US Army Combat Capabilities Development Command (DEVCOM) Ground Vehicle Systems Center (GVSC) and Tank-automotive & Armaments Command (TACOM) are looking for alternative manufacturing methods for hard-to-procure parts. A team of three – Kevin Thomas, Andrew Smail and Mitchell Scott, with DEVCOM GVSC - visited SIAD in early February for the purpose of creating digital twins for parts that do not currently have technical data packages associated with them for the Battle Damage Repair and Fabrication program.

GVSC, located at Detroit Arsenal, Michigan, is one of the US Armed Forces’ research and development centers for advanced technology in ground systems. One of GVSC’s roles includes sustaining platforms through their lifecycle, ensuring that they remain operational. When Soldiers in the field need parts, they send a request to TACOM. If the parts are not readily available, TACOM then is able to have GVSC develop engineering artifacts for Rock Island Arsenal-Joint Manufacturing and Technology Center (RIA-JMTC) to manufacture them using Additive Manufacturing (AM) techniques. These parts can be used temporarily until Original Equipment Manufacturer (OEM) parts become available. TACOM is therefore looking for temporary alternative manufacturing methods to OEM to improve readiness.

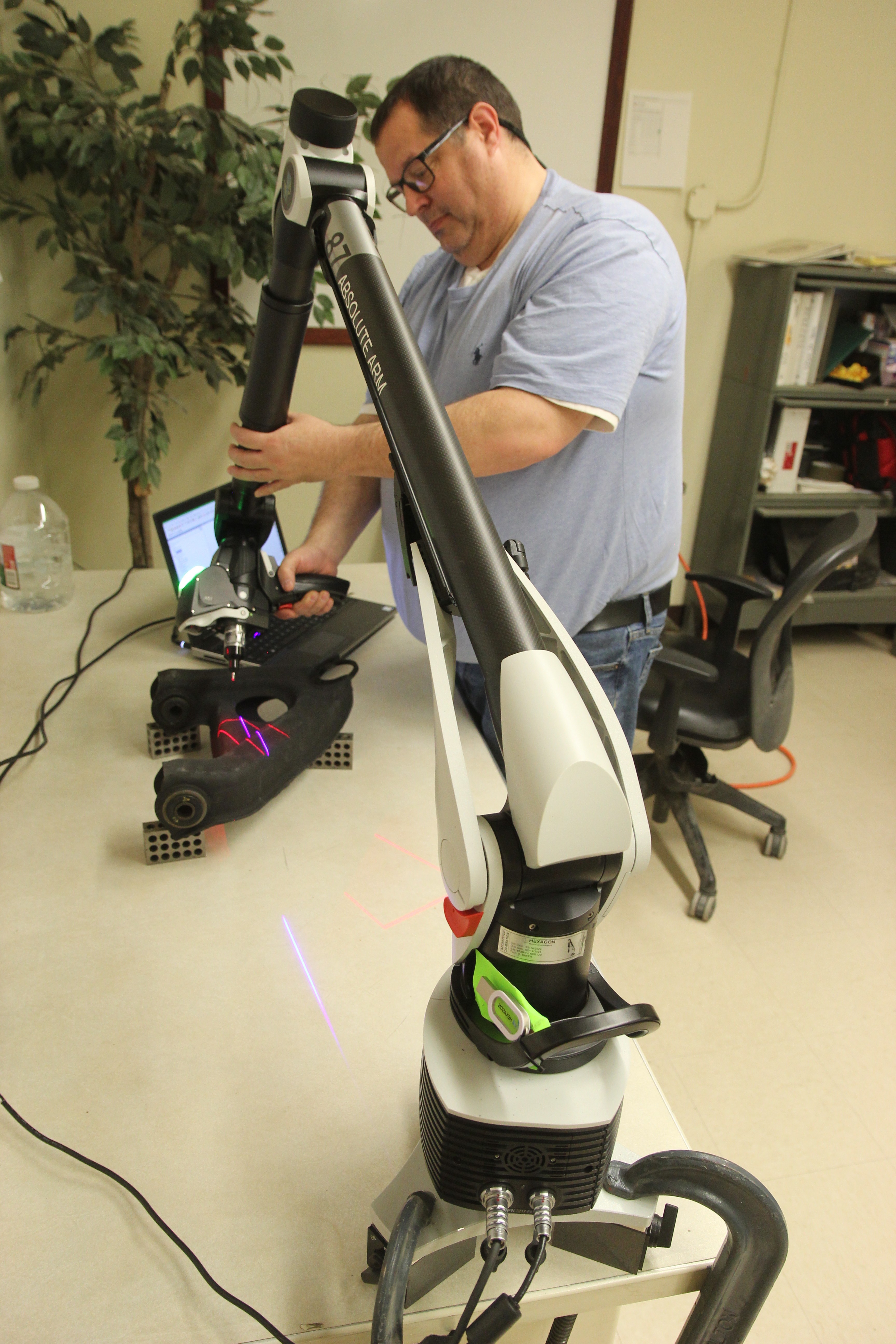

SIAD’s Ground Tactical Vehicles branch, Maintenance directorate, worked in tandem with the visiting GVSC team. Larry Roberts and Jody Smith, Powered Support Systems Mechanic Supervisors, as well as Kayla Butkins, Logistics Management Specialist, assisted the visitors with setting up equipment and scanning parts. SIAD mechanics pulled 17 parts, in addition to four that were found in AJ1 Supply Support Activity (SSA). Depending on their size, complexity, and reflectivity, average parts can take up to two hours to be scanned. Once scanned, the GVSC modeling team will be able to create a shell, then a model, and finally a drawing for the part. The Technical Data Package (TDP) will finally be uploaded in an approved data repository for future fabrication needs.

SIAD is looking forward to deepening its relationship and cooperation with GVSC to provide maintenance support at the tactical edge.

Social Sharing