In a combat setting, situational awareness is everything. Being able to see clearly, no matter the situation, is a crucial part of staying ready to fight and win against an adversary.

That’s why the U.S. Army has optical fabrication capabilities positioned in forward locations, such as in Germany and Korea, to provide quick-turn services on various products that keep service members ready to go, including prescription glasses, gas mask inserts, flight goggles and various types of eye protection.

“Service members overseas can technically order glasses through state-side vendors, but this process is often slower and less efficient, leading to delays that could impact readiness and operational effectiveness,” said Staff Sgt. Anthony Perez, noncomissioned officer in charge for the Optical Activity Division at the U.S. Army Medical Materiel Center-Europe.

Based in Kaiserslautern, Germany, USAMMC-E and its sister organization, the U.S. Army Medical Materiel Center-Korea, serve as theater lead agents for medical materiel, also known as TLAMMs, for their respective regions.

Both TLAMMs are direct reporting units to Army Medical Logistics Command, the Army’s Life Cycle Management Command for medical materiel.

Each with a standing optical fabrication mission, the centers produce thousands of pieces of corrective eyewear every month, ensuring Solders, Sailors, Airmen and Marines have what they need for target acquisition, equipment operation and navigation.

“Without this immediate support, relying on external vendors could jeopardize the effectiveness and safety of military operations,” Perez said. “TLAMMs play an essential role in keeping service members mission ready.”

While technology advances in recent decades have improved time-around times and accuracy of production, the impetus for optical fabrication itself dates all the way back to about 1917, when the U.S. entered World War I, according to historical reports.

Prior to that, the standing Army was relatively small, and enlistees were required to be young, healthy men with good uncorrected vision. That all changed when 2.8 million men were drafted into service, a number that increased to four million by the end of the war.

To meet manpower requirements, the Army lessened its vision requirements, accepting many men with significant ametropia, or a refractive condition of the eye that results in blurry vision – near, far or both.

To correct these issues, short of surgery, the Army pushed resources to establish forward optical fabrication labs to provide prescription spectacles or contact lenses for service members as combat power surged.

Similar ramp-ups in manpower prior to subsequent military engagements, including World War II and the wars in Korean and Vietnam, again brought forward optical fabrication to the forefront.

Through the decades, ophthalmic care has continued to grow, bringing the Army to where it is today with a recognized career field, comprised of multiple military occupational specialties for enlisted and commissioned officers.

At the same time, the focus on optical fabrication has sharpened as well, assisted by new technologies that increase efficiency, provide for a wider array of products and lessen turn-around times for service members.

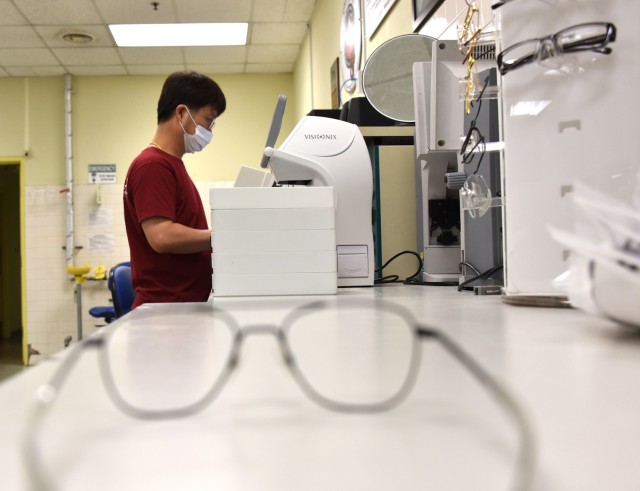

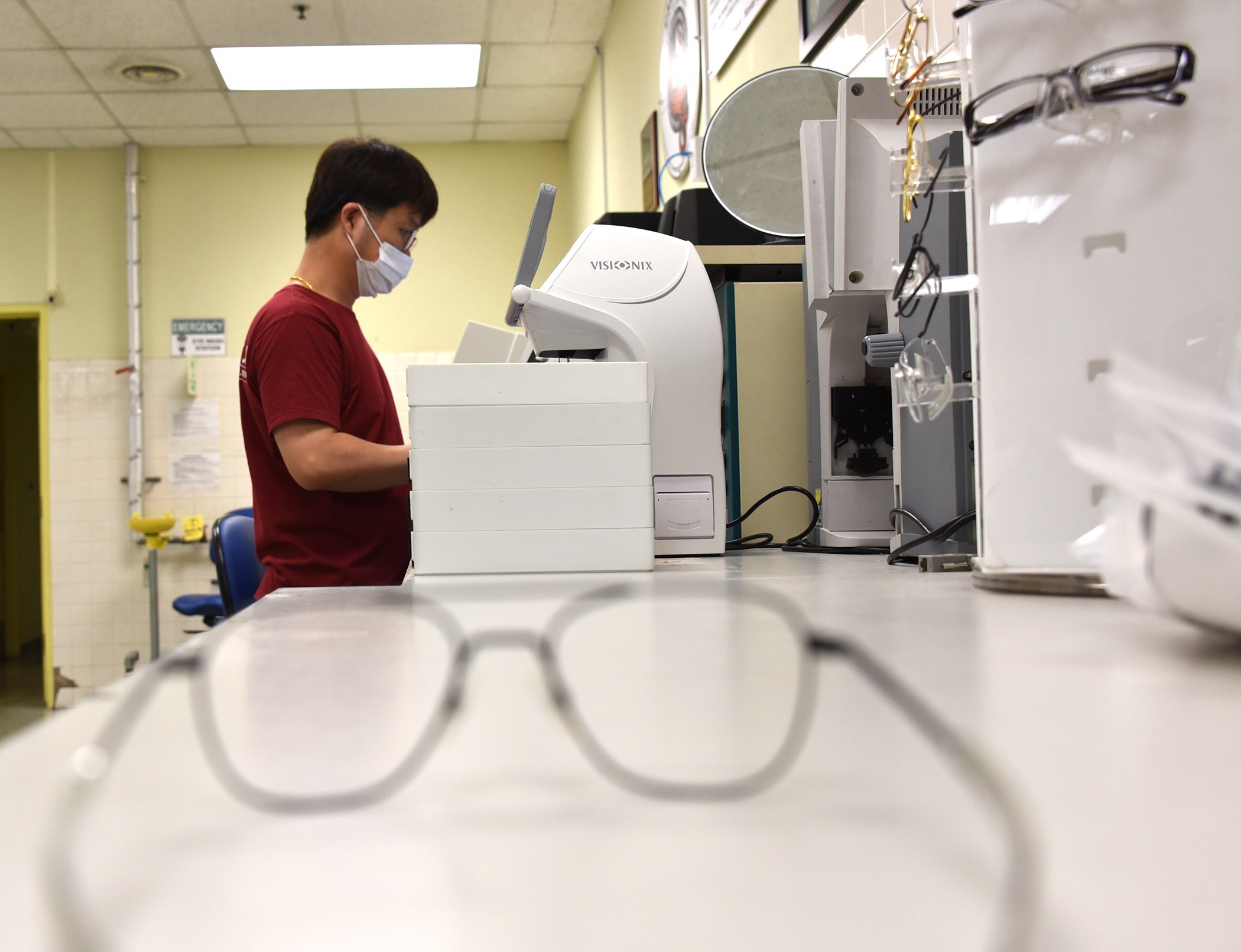

“Optical labs have seen a lot of technology advancements in the industry, such as automatic equipment that streamlines the process and speeds up processing times,” said Sgt. 1st Class Jaylan Barron, NCOIC for USAMMC-K’s optical fabrication lab.

After receiving an order, production begins by pulling the required lenses from lab stock and using specialized equipment, such as a lensometer, to verify the desired prescription of each corrective lens. They are then sized, smoothed and inserted into each piece of eyewear. The process also includes tinting, in some cases.

From there, they are inspected for quality assurance and readied for shipping to the user, sometimes within 24 hours of receiving the initial request.

“It’s typically a three-day process from start to finish, but we can get glasses done and ready to ship within the same day,” Barron said.

In addition to its fixed-based optical lab, USAMMC-K also supports a standing tactical mission that involves the deployment of a mobile lab in the event of a “transition to hostilities” in the region, ensuing optical fabrication services are immediately available to Soldiers arriving in Korea.

Barron said USAMMC-K has one nested Soldier at the TLAMM from the 563rd Medical Logistics Company, who works closely with the 221st Optical Detachment that operates the mobile fabrication unit.

“Together, we stand ready to support the needs of the warfighter in any contingency here on the peninsula,” Barron said.

Social Sharing