The Army supports the readiness of its equipment and units with a maintenance and supply system that ensures Soldiers have the supplies, equipment, and spare parts they need, when they need them, to accomplish their mission. However, even the best system cannot always respond fast enough to meet readiness requirements, so Army sustainment professionals are always looking for innovative solutions to reduce or eliminate excessive lead-times, improve readiness, and meet Soldier needs. One of these innovative solutions is Additive Manufacturing (AM).

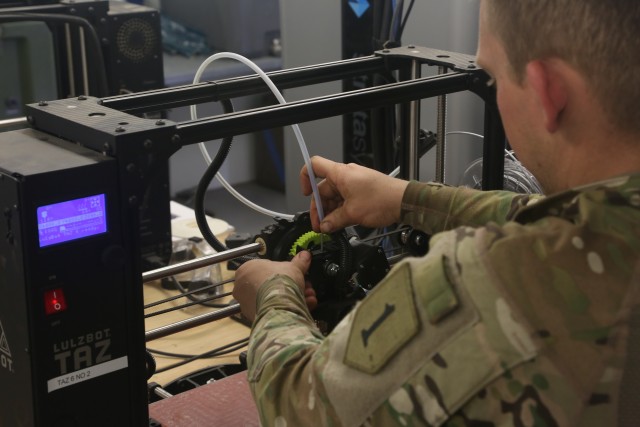

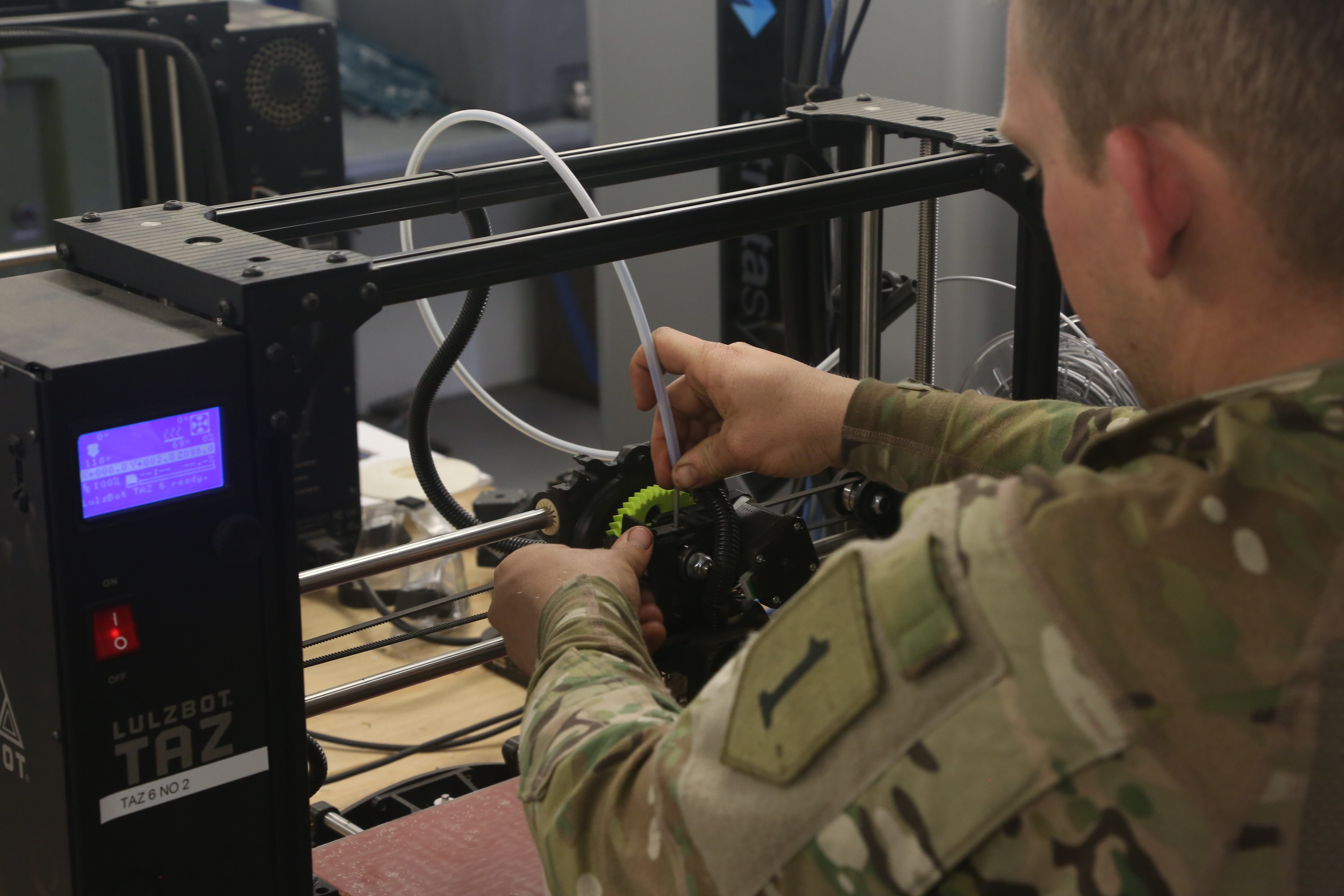

Additive manufacturing, also known as three-dimensional (3D) printing , builds parts layer by layer from 3D digital models. AM has the potential to greatly enhance the Army's ability to resolve supply chain challenges by providing the capacity to produce usable temporary parts at the point of need as well as fully qualified permanent parts from the industrial base. When used in combination with scanning technology and Computer Aided Design (CAD) software, AM empowers Soldiers to solve materiel problems at the local level.

Responding to direction from the Secretary of the Army to adopt and operationalize AM throughout the force, the Army has made great strides in developing and implementing a multi-echelon approach to AM. This approach, governed by the Army Additive Manufacturing Campaign Plan, provides a way ahead for achieving layered and adaptable capabilities throughout the force that will improve readiness and enhance Soldier capabilities.

This echeloned approach to AM provides for developing capability at three levels: unit, support maintenance, and the Organic Industrial Base (OIB). It also ensures that the training base and Department of the Army policy supports and encourages the use of AM for readiness and Soldier innovation while also giving the unit commander the necessary tools to effectively manage risk.

At the unit level, 3D printers can empower Soldier innovation and enhance readiness by producing accurate models and training aids, such as realistic scale model buildings for improving rehearsals at both individual and collective training events. Headquarters Department of the Army EXORD 050-18 provides guidance to all Army units using local purchasing authorities to obtain commercial off-the-shelf (COTS) 3D printers, and supporting scanners and software. It also advises on printer types, price thresholds, uses, limitations and the necessary approvals when buying the equipment and supplies. It also provides a decision tree to help commanders decide when and how to use the printers, within policy, training, and certification limits as defined in the EXORD, as well as points of contact for assistance.

At the support maintenance level, Project Management Office Sets, Kits, Outfits, and Tools is fielding the Metal Working Machine Shop Set (MWMSS). The MWMSS will include a polymer 3D printer and scanner combination that, when added to the skills and knowledge of the Allied Trades Warrant Officers and NCOs provide commanders with a new and flexible tool for producing Battle Damage Assessment and Repair parts on an emergency basis.

The polymer 3D printers currently authorized in units' and maintenance organizations' Allied Trades Sections are capable of producing specialized tools, jigs, and fixtures, which improves readiness by making applicable maintenance procedures simpler and easier to perform. In addition, to support both the unit user and the Allied Trades MOSs, the Army has established the Repository for Additive Parts for Tactical and Operational Readiness (RAPTOR), which is available at https://picac2w6.pica.army.mil/Raptor/Login.aspx. RAPTOR is the Army's growing repository of downloadable digital models for use with AM 3D printers. Army users with a CAC may access the system.

At the highest echelon of the Army's operationalized AM capabilities, the depots, arsenals, and ammunition plants of the Army's Organic Industrial Base have developed strong AM capabilities, having used AM for many years to support their internal production lines to overhaul, rebuild, and reset Army equipment. Building on this history, the Advanced Manufacturing Center of Excellence (AM COE) at Rock Island Arsenal's Joint Manufacturing and Technology Center (JMTC) furthers these capabilities by serving as a focal point for operationalizing AM across the Army. It provides AM-produced polymer or metal parts directly to the customer in support of the readiness needs of the Army. The AM COE also provides a technical assistance help desk to assist units with any aspect of AM. Contact the AM COE Help Desk by email at usarmy.amsupport@mail.mil for assistance.

The Army is committed to operationalizing AM throughout the force. It is taking a multi-echelon approach in pursuit of a holistic vision to cover the Army's readiness needs. AM provides unique capabilities and opportunities to augment the supply chain by providing critical and hard to obtain readiness drivers quickly and closer to the point of need. In this way, AM empowers Soldiers to find innovative solutions to their everyday challenges.

----------------

Dr. Nelson Williams is the Chief, Sustainment Maintenance Division, HQDA G-4, where he serves as the senior civilian supervisor for the Sustainment Maintenance Division responsible for supervising and directing the Army wide Maintenance policies and related programming and budgeting functions for wholesale and retail maintenance functional areas. He serves as one of the senior Army Maintenance Management Specialist for maintenance policies and procedures and as special advisor and consultant to the maintenance director and the Army G-4 on Maintenance matters. He represents the Army G-4 in maintenance forums, conferences and meetings. Dr. Williams holds a Doctorate of Divinity; a BS in Business Management; and is a graduate of Army Management Staff College. Dr. Williams previously received the President of United States' Lifetime Achievement Award.

Retired Col. David R. James, Senior Industrial Base Analyst from Booz Allen Hamilton. Holds Masters Degrees in Administration from Central Michigan University, and National Security and Strategic Studies from the United States Naval War College. A certified Project Management Professional and member of the Ordnance Order of Samuel Sharpe. Recently studied Additive Manufacturing for Innovative Design and Production from the Massachusetts Institute of Technology.

---------------

Social Sharing