As the commander of the Forces Command (FORSCOM), Gen. Robert B. "Abe" Abrams leads a team of over 776,000 Soldiers and 96,000 civilians in building and sustaining readiness across all components of America's Army.

A graduate of the United States Military Academy, Abrams has developed a reputation for training Soldiers and leading them in combat throughout his 36 years of service. Here are his thoughts on the future of Army sustainment.

Q: How has expeditionary battlefield sustainment evolved throughout your career?

A: Sustainment has evolved through three distinct periods: pre-Operation Desert Storm, Desert Storm to about 2005, and 2005 onward. During the Cold War, we were postured to assume our wartime mission at a moment's notice. As a lieutenant and captain, I was stationed in Germany. Europe was a very mature theater with a robust sustainment architecture. Exercises stressed our sustainment systems with a focus on moving units over long distances and sustaining them with refuel on the move.

I participated in six Reforger exercises. These were large-scale events that brought in 80,000 Soldiers in addition to the 250,000 already stationed in Europe. The exercises did an excellent job at the strategic level, but they really didn't challenge at the tactical level on skills such as reconstitution and battle damage assessment and repair.

We started to see change with the establishment of the National Training Center at Fort Irwin [California], where we learned the hard lessons associated with sustaining the force and high-tempo operations in an austere environment. What sprang from this was the idea of fixing forward. We learned that it was essential to fix forward to provide as much combat power as possible.

During Desert Storm, the theater was initially very immature and U.S. forces were 100 percent reliant on the echelons of sustainment we brought with us. There was no depth to supply; units had to sustain themselves on the battlefield until the supply base was built up. I was in the 1st Cavalry Division.

We loaded our equipment the second week of September 1990 and occupied an assembly area in the middle of the Saudi Arabian desert, 15 kilometers from the nearest road. We quickly recognized we would outrun our supplies if we did not begin to stock up.

To help solve this problem, the U.S. Central Command built five large logistics bases--proverbial mountains of iron. The initiation of combat in Iraq was predicated on a number of things; one of them was the buildup of supplies and forces. Unfortunately, that became our mindset for sustainment. We were always going to have these mountains.

For the invasion of Iraq in 2003, our Army followed the model of the Gulf War. Kuwait became home to a large logistics footprint that was well-established before the offensive into Baghdad. It was effective; when I deployed to Iraq in 2004, my unit had all the supplies and support we needed. I don't think I ever dropped below 10 days' worth of fuel inside my brigade; we never went without water or food or repair parts.

From 2005 on, our Army got very comfortable with forward operating bases. Tactical infrastructure had their full complement of basic load. But as a result, our skills--of being able to sustain ourselves in an austere environment at a high tempo within an immature theater--atrophied.

Today, with our focus on conducting continuous operations in austere environments, we have to be able to sustain ourselves at echelon and over distances and at a high tempo. And every piece of the sustainment enterprise has to do its part.

Q: With the shift back to decisive action training, what observations do you have about our modular force structure and doctrine?

A: Our modular force structure for sustainment is about right. The design is optimized for fixing forward, providing commanders at every level the tools they need to sustain themselves in an austere environment. Over the last three years, we have demonstrated our ability to do this. However, we've also recognized at the training centers that we're missing an echelon of maintenance that we used to have.

For the systems in our combat formations, all the mechanics are assigned at the lowest unit level. But a gap occurs when parts are not available or repairs take 48 to 72 hours. We actually have to evacuate or leave the equipment or vehicles for someone else to recover or repair so that the unit can continue the offensive. We've got to make some hard choices because there is a finite amount of force structure. Overall, though, the force structure and doctrine for sustainment is actually pretty good. It works but it takes practice.

Q: Can you discuss the "Ready Now" concept and how it is building readiness across the force?

A: Army Force Generation (ARFORGEN) was designed to prepare units to be at the highest state of readiness at a specific point in time for a specific mission. Quarterbacked by FORSCOM as the force generation provider, the entire Army enterprise would line up all the systems--personnel, supply, training, and modernization--to assemble units over time. The ARFORGEN model ensured unit readiness on the day they were due in theater, the latest arrival date (LAD).

Under ARFORGEN, units only needed to be ready in time for their LAD. There was no incentive to being ready early or for sustaining readiness. We really lost this idea of being ready all the time.

Now, as we've drawn down out of Iraq and Afghanistan, world events in other regions have created an environment that is volatile, uncertain, complex, ambiguous, and dangerous. It's unpredictable and requires our Army to be prepared and ready at all times, rather than only as determined by a LAD.

Today, we're creating a sense of urgency throughout our entire Army to be "ready now." The Army is raising its game--in training, in readiness, in mobilization. We have shifted our training focus to counter these emerging threats while simultaneously sustaining our global commitments. We have the ability to be ready all the time, and that starts with changing our mindset. We need to go back to the readiness mentality that I grew up with as a young officer in Germany.

During the Cold War days, if the division called our squadron headquarters and gave the code word for "alert," we had two hours to recall everybody. It didn't matter the day or time; we had two hours to get everybody in and three hours to get everything out of our arms rooms--from every weapon to all of our nuclear, biological, and chemical defense equipment. Then, we went down to the motor pool, and got the vehicles started. At four hours, we had to be ready to leave for action.

We were ready all the time. Your rucksack "go bag" was packed and at the front door. Your vehicles were constantly in a state of readiness, always operational; you never went home if a vehicle was broken because you never knew when you would get alerted. We've got to get that mentality back in the Army.

When I talk about readiness and "Ready Now," it's not tied to any one plan or world problem; it's about a mentality we need to have. Over the last 30 years, our Army has had the luxury of choosing the time and place of employment, which allowed us to build up our forces beforehand.

Our future enemies may not afford us time to prepare, and that requires our entire Army to be ready now.

Q: How has replicating the operational environment in training enabled sustainment units that are deployed?

A: With the transition to large-scale combat operations training, it became apparent that a number of our fundamental skill sets had greatly atrophied. One of these shortcomings is with the diagnosis of maintenance faults.

Having nonstandard equipment like MRAPs [mine-resistant ambush-protected vehicles] and Gators in our inventory required our mechanics and warrant officers to learn whole new skill sets. Impressively, our Soldiers excelled at working on very unique, nonstandard types of equipment. Diagnosing a Bradley or Paladin, however, became an increasingly under-practiced skill. Again, performance at combat training centers and home stations highlights our deficiencies. We underestimated how out of practice we were with diagnosing some of our major combat systems.

While we have a good metric for diagnosis and testing, it is time-consuming. Getting back an inconclusive result from diagnostics, such as no evidence of failure (NEOF), prolongs the process. If you look at our NEOF rates, they had grown pretty high.

Additionally, repairs were also taking twice as long, for both ground and air. While our ground mechanics were deploying with units but working on nonstandard equipment, our aviation mechanics were not even deploying forward. Instead, we contracted our aviation maintenance because of limits on the number of personnel in theater. Predictably, green suit aviation maintainers' skills atrophied. Now that our Soldiers are back on the flight line doing phase maintenance inspections, they are taking two and three times longer to accomplish their tasks.

The training centers have been driving this issue to the forefront and have charted a path forward. Working with the Combined Arms Support Command, we [FORSCOM] created the Unit Diagnostics Immersion Program, a mobile training team in diagnostics skills and repair.

We've also partnered with the Army National Guard at Camp Dodge, Iowa, to pilot the Master Diagnostician Training initiative, a great two-week diagnostics course for tank, Bradley, and Paladin mechanics. That is a total Army solution that increases the technical skills and capabilities of our mechanics.

We're now starting to see results, especially in our armored units rotating to Eastern Europe, Korea, and southwest Asia. There's improvement in our operational readiness rates, we're lowering our NEOF rates, and we're able to sustain the fleet better. For our aviation fleet, we've implemented five aviation business rules. One of them is that aviation units will deploy with their mechanics. In 18 months, we've seen significant improvement in Army-managed item and aviation operational readiness rates as a result.

Q: What is your advice for balancing training requirements with available time?

A: We should only do those things that directly contribute to readiness. People equate readiness to their ability to fight and conduct their wartime mission, but there are many facets. Readiness is holistic; it encompasses equipment readiness, personnel availability, supply, and training readiness, and those components need to be prioritized.

Commanders at every echelon must clearly communicate their priorities while being sensitive to the demands placed on those below. There is inherent risk in prioritization, and I expect leaders at every echelon to assume risk for those below them. Commanders must tell subordinate units not to do things that are low priority and [instead] focus on what is most important.

Units should also only train at a tempo that can be sustained. A couple years ago, in the spirit of regaining proficiency in our warfighting skills, we trained at such a rate that we lost focus on fundamental support tasks. We can only maintain a tempo that can support performing preventive maintenance checks and services, conducting inventories, receiving new equipment, and turning in equipment to get rid of excess to standard.

We need to keep in mind that we have deployed (to either rotational missions or combat deployments) at a tempo under 1:2 since 2003. Even though our commitments in Iraq, Afghanistan, and Syria have decreased, our other worldwide commitments have increased. Our Army is really busy. And this makes time our most precious resource.

Q: What recommendations do you have for sustaining supply and maintenance readiness levels?

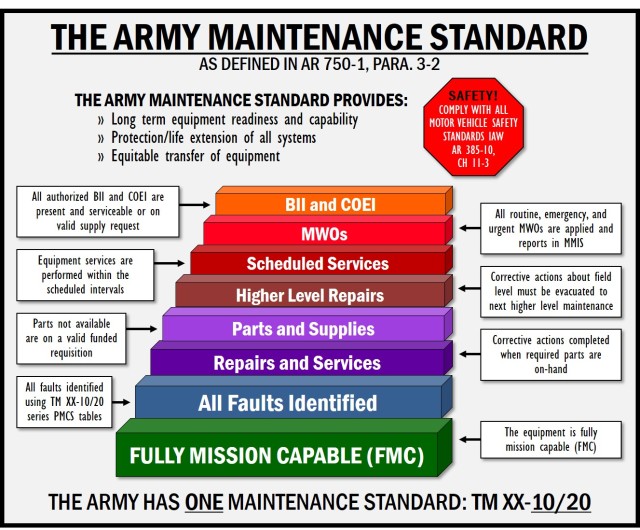

A: The command maintenance program and the command supply discipline program are absolutely key commander's programs. Commanders must be ruthless in enforcing standards. The maintenance standard in our Army is 10/20, and that's non-negotiable. (See figure 1.)

In October 2013, a 16-day government shutdown followed by continuing resolutions caused the Army to institute a maintenance standard of "fully mission capable plus safety." The program required the Army to stop ordering repair parts for bench stock, shop stock, authorized stockage lists, and warehouses.

But by 2014, those austere measures were lifted and the standard returned to 10/20. Our formations have been slow to realize the change and our maintenance standards have suffered.

The maintenance of our systems is the lifeblood of the Army in terms of our ability to fight, and we have to be relentless in adherence to 10/20 standards. Commanders can assume risk in other areas, but our fleet has to be ready.

Q: Are you comfortable with our force structure and readiness to meet early-entry requirements?

A: I think our force structure across all three components is about right. Based on our deployment timelines, I think we have adequate echelons of regular Army above-brigade sustainment units to sustain us for the first 20 to 40 days, and that will allow the Guard and Reserve time to get in place. The key is continuing to ensure our Guard and Reserve get the training money they need to sustain a certain level of readiness. They need to be able to deploy in short order.

It goes back to strategy. We should assume our potential enemies are not going to give us time to build up. We need a blunt force that is combat-capable, but we have a finite amount of force structure. So we are balancing everything that gives us adequate capacity to be able to respond, sustain what we're doing, protect the homeland, and give time for those Guard and Reserve echelon-above-brigade units to be able to deploy.

Q: As the FORSCOM commander, what concerns you from a sustainment perspective?

A: Not-mission-capable time for supply is the biggest challenge for our ground fleets. From 2004 to 2015, we did not put a lot of demand on industry for parts for tanks, Bradleys, Paladins, and other systems. As a result, industry had little incentive to continue producing parts for these combat systems. The Army was left with only what we had in warehouses; the availability of repair parts was strained. Now, we're putting demand back on the system; it's slow to respond, but it's trending in the right direction.

Continuing resolutions and budget unpredictability are also concerning. While we're optimistic about recent developments, an unpredictable budget certainly impacts our ability to sustain our fleets over time.

But we do have unbelievable maintainers and sustainers; the work they do is tremendous. In my lifetime, we have not gone without, and that is a credit to our sustainment community. They have been anticipative, responsive, flexible, and agile. If you look at the eight imperatives of sustainment over my 36 years in the Army, our sustainers stepped up to the plate every single time.

Q: You have commanded at every level in the Army. What is the biggest piece of advice you have for Soldiers?

A: First, give your best effort every day. I'm an optimist; I'm a glass-half-full kind of guy. I actually think every Soldier wakes up every day wanting to contribute and do their best.

Second, your service matters, regardless of how many years you've served. The world is a dangerous place, and it's as volatile and uncertain as ever. If you believe in our country, we must have an Army that can protect it. It takes special people who want to serve their country in uniform. Not everyone is physically capable of doing it, and neither is everyone willing. To those who are willing to serve, I say thank you and I'm proud to serve alongside you.

--------------------

Arpi Dilanian is a strategic analyst in the Army G-4's Logistics Initiatives Group. She holds a bachelor's degree from American University and a master's degree from Rensselaer Polytechnic Institute.

Matthew Howard is a strategic analyst in the Army G-4's Logistics Initiatives Group. He holds bachelor's and master's degrees from Georgetown University.

--------------------

This article was published in the May-June 2018 issue of Army Sustainment magazine.

Related Links:

Army Sustainment Magazine Archives

Social Sharing