Redundancies have been created in the sustainment support structure to cover worst-case scenarios. However, a leaner sustainment footprint may be worth considering.

One unit with overlapping logistics support is the general support aviation battalion (GSAB) forward support company (FSC). Because of how the GSAB is employed, the FSC is almost always co-located in an area of operations with other logistics elements. This overlap creates redundancies in field feeding, petroleum distribution, and ground maintenance.

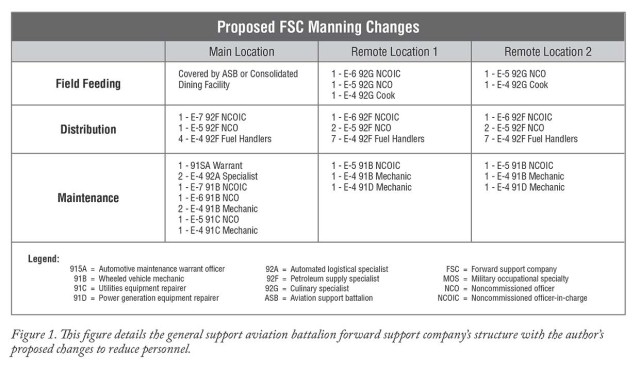

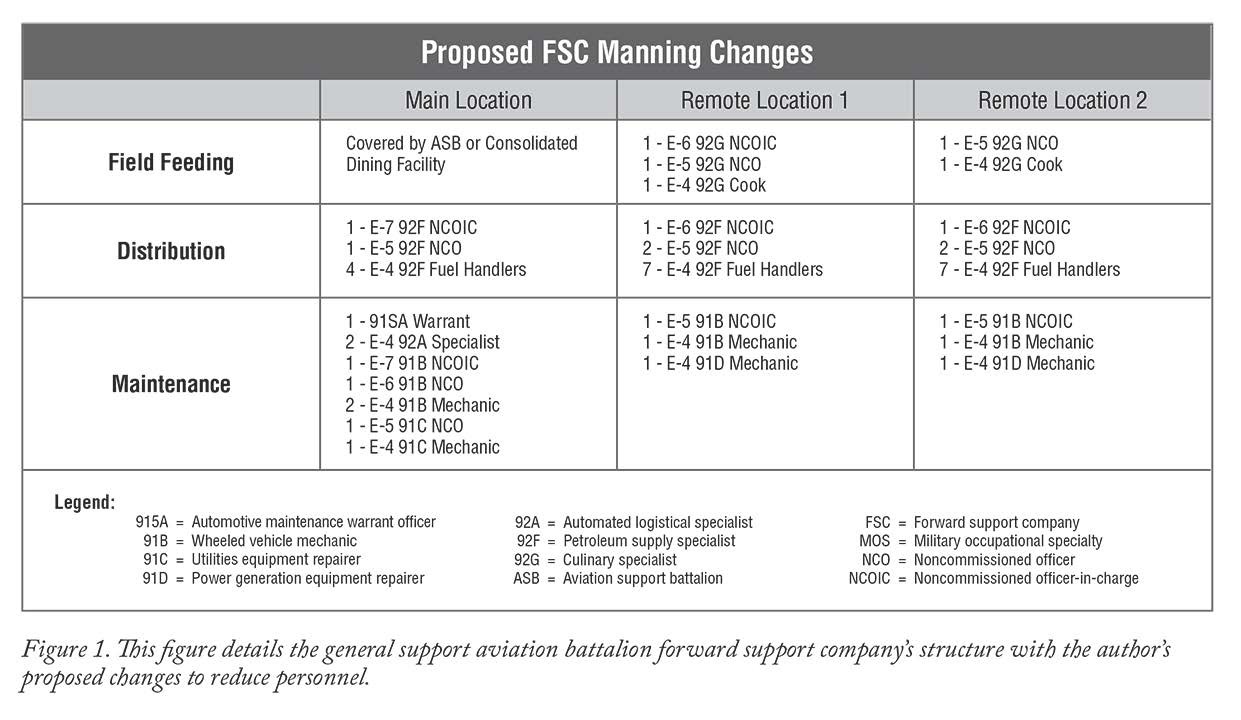

While a robust GSAB FSC can be a force multiplier when used to its fullest extent, the current operational environment and its constraints leave the FSC underutilized. Thus, the FSC could be downsized to a platoon-sized element that falls under the headquarters and headquarters company. (See figure 1.)

THE GSAB STRUCTURE

The mission of the GSAB is to provide aerial command and control support, limited air assault capability, air movement, and medevac support for the assigned area of operations. The GSAB consists of seven companies: the headquarters and headquarters company, command aviation company, heavy helicopter company, medevac company, aviation maintenance company, air traffic services (ATS) company, and the FSC.

The GSAB is a versatile unit that can easily be split for decentralized operations. Each flight company with the exception of the command aviation company is task-organized with the ability to be split into three elements for separate operations. The mission of the command aviation company necessitates that it be located with the brigade and battalion headquarters.

The air traffic services and aviation maintenance main elements are located with the headquarters but have small teams that support forward operations as the mission dictates.

The FSC is intended to be utilized at forward locations, while the aviation support battalion's (ASB's) headquarters support company and distribution company provide support at the headquarters location.

Because of the financial and force multiplier value of aviation assets, the main element of the aviation brigade and GSAB are typically located at the most secure locations within the area of operations. Any elements that are pushed forward should still be located with battalion-sized combat units. A forward support medevac team could possibly be emplaced at a company-sized location.

FIELD FEEDING

The GSAB is authorized a field feeding section that consists of 11 enlisted Soldiers, a containerized kitchen, and two assault kitchens. By doctrine, the field feeding section can support one consolidated and two remote locations.

Looking at the structure of the GSAB as a whole, this support structure makes sense; through task organization, the GSAB can operate at three separate locations, one consolidated and two remote. The containerized kitchen can support up to 800 Soldiers per meal, and the assault kitchen can support a company-sized element per meal.

Each remote location is run by two culinary specialists. The consolidated location is run by the remaining nine culinary specialists. When you look at the numbers, the manning is appropriate to sustain long-term operations.

The overlap in field feeding personnel occurs because of where the aviation assets are emplaced. The field feeding structure makes sense only if the GSAB were to deploy without external support. However, the main element of the GSAB will most likely be co-located with the brigade and, thus, the ASB. With an ASB at the location, a combat brigade and various support elements with their own field feeding sections most likely will also be present.

The field feeding structure within the theater aviation brigade contains 19 ASB Soldiers in addition to the FSC field feeding sections when the attack and assault battalions are co-located with the ASB. This simply accounts for the military personnel assigned to the aviation units.

Locations that have an aviation brigade are likely to have a consolidated dining facility augmented by local contractors, leaving aviation brigade culinary specialists to execute non-MOS-related duties for the duration of their deployment.

In many remote locations, the forward aviation element can receive food from the land-owning field feeding section or an internal assault kitchen operated by two culinary specialist Soldiers.

Considering this information, the field feeding section of the GSAB FSC can be downsized to five personnel: one staff sergeant, two sergeants, and two lower enlisted Soldiers. This structure would allow the field feeding section to support remote locations or augment the main element location if military personnel are providing sustenance.

Attack or assault battalions will also likely have assets co-located at the remote location. The two GSAB FSC culinary specialists can feed the entire remote element, freeing up the attack or assault battalion culinary specialists to augment the main location if required.

PETROLEUM DISTRIBUTION

The GSAB FSC distribution section is authorized 50 Soldiers, two advanced aviation forward area refueling systems, 22 heavy expanded-mobility tactical truck (HEMTT) fuel tankers, six trailer-mounted modular fuel systems, and five HEMTT tanker aviation refueling system.

The class III (petroleum, oils, and lubricants) section is split into heavy, utility, and air ambulance sections. But, in reality, petroleum supply specialists within the GSAB can fuel any aircraft at their assigned location regardless of their section. Having personnel fuel only specific aircraft would be extremely inefficient and a poor use of assets.

The ASB distribution company has a class III section of 28 personnel whose mission is to receive, store, distribute, and issue fuel. The distribution company also has an aircraft refueling section of 11 personnel. An attack or assault battalion has a distribution section of more than 30 petroleum supply specialists.

FARP OPERATIONS. The ASB distribution company's class III section is responsible for forward arming and refueling point (FARP) operations at the main battalion and brigade location. This structure leaves 50 petroleum supply specialists available for the GSAB's remote locations.

FARP manning is dictated by mission, enemy, terrain and weather, troops and support available, time available, and civil considerations. However, the most likely scenario can be used to determine manning while allowing for short-duration surge capabilities.

During normal operations, a two- or four-point FARP can be manned by five personnel or a total of 10 personnel for 24-hour operations. Hot FARP can be used exclusively, or cold fuel can be used for steady-state operations without requiring any additional personnel.

A high operating tempo would require a surge to more than five personnel working at the same time for short durations. If fast-paced operations are expected for an extended amount of time, the location should be augmented ahead of time. Augmentees can come from the ASB, assault or attack battalion FSCs, or internally. This type of manning would be expected at locations with multiple airframes.

In locations with a forward support medevac team, five personnel can provide 24-hour, on-call coverage since the operating tempo should not be as high.

The GSAB FSC can meet most theater aviation brigade fuel-handling requirements with 26 Soldiers. This would allow for the FSC to man two remote locations for 24/7 operations and provide surge capability or coverage of a jump FARP.

Any additional manning requirements can be filled through augmentation from the ASB or the attack or assault battalion FSCs. With the addition of attack and assault battalion FSC personnel, the aviation brigade should be able to sustain at least six remote FARPs 24/7.

Again, this analysis only accounts for military personnel. In many instances, contractors are brought in to provide cold fuel at robust operating locations. When these contracts are put into place, fuel-handling personnel conduct non-MOS-related duties.

BULK FUEL DELIVERY. The ASB, the combat sustainment support battalion (CSSB), or contractors should deliver bulk fuel. All deliveries should be direct and minimize handoff, even at remote FARPs. This would allow the GSAB to reduce the number of HEMTT fuel tankers required. The CSSB could line-haul HEMTT fuel trucks to the remote locations if FSC internal personnel were not available to conduct the convoy. An alternative would be replace HEMTT fuel trucks with fuel bladders.

GROUND MAINTENANCE

The GSAB FSC maintenance section is authorized 47 personnel and a complete wheeled-vehicle repair package to include standard automotive tool sets, a forward repair system, and contact trucks. Specialty repair personnel are also available to repair small arms, night-vision devices, communications equipment, and other unit equipment. The ASB has a robust maintenance section of 83 personnel. The assault and attack battalion FSCs have maintenance sections similar to that of the GSAB FSC.

WHEELED VEHICLES. The flight companies have few wheeled vehicles. Most of the battalion's wheeled vehicles are in the FSC, the aviation maintenance company, and the headquarters element. The number of GSAB vehicles can be greatly reduced, which would allow for the maintenance section to be downsized.

The GSAB would maintain flight-line vehicles and a small element of medium tactical vehicles (MTVs) and humvees. This reduction would allow the FSC to reduce its wheeled-vehicle capability accordingly. Fewer wheeled vehicles would also mean fewer mechanics would be needed.

The GSAB can use its heavy-lift assets to self-deploy equipment, work with the local CSSB to line-haul large amounts of equipment, or have the Air Force airlift equipment to the area of operations.

SPECIALTY REPAIR. Specialty repair personnel reside in both the GSAB and the ASB. Their skill sets are used for low-priority equipment that can be sent to the rear for repair. These GSAB personnel would only be used to their fullest extent if the battalion is deployed as a standalone element. In that case, the GSAB could rely on the local CSSB or other support elements for these repairs.

HEAVY ASSETS. The GSAB FSC maintenance capabilities should be tailored to support a main location and two remote locations. The remote locations can use an MTV and a contact truck to support forward maintenance operations. I propose that this element consist of two wheeled-vehicle mechanics and a generator mechanic.

A wrecker would not be needed because the element would not be expected to convoy. Anything outside of the element's ability to fix could be line-hauled by the local ground element back to the FSC's main maintenance location or directly to the ASB.

I also propose placing a palletized load system with a forward repair system, an MTV, and a wrecker at the main FSC maintenance location and staffing this location with a maintenance warrant officer, two production control specialists, four wheeled-vehicle mechanics, and two generator mechanics. Any work that the section could not complete itself in a timely manner would be sent to the ASB maintenance section.

CONVOY SECURITY

Maintaining the current strength of the GSAB FSCs can be justified if the units become tactically self-sufficient. Currently, the GSAB FSC does not have the convoy protection platforms needed to successfully provide logistics convoy security. If the FSC had convoy protection platforms, then it would not have to rely on outside units for convoy security.

Convoy protection platforms would also enable the FSC to fill the GSAB's downed aircraft recovery team needs. This would allow the aviation maintenance company to focus on maintenance while the downed aircraft recovery team and its convoy security stayed within the battalion.

Doctrinally, these changes would not be difficult to implement. The hardest part would be obtaining convoy protection platforms.

Redundancy is necessary because operational environments are always changing. Today's logistics requirements may not be the same as tomorrow's requirements, so having a robust logistics structure makes sense and should be maintained. Support units must ensure they can provide the tactical support that contractors cannot to maintain relevance during times when redundancy and reliance on contractors are high.

If changes to the personnel structure of the GSAB FSC must be made, doing it in the ways described in this article would ensure the required support capabilities are maintained. In this case, tactical capability would have to be provided by outside resources and units.

_____________________________________________________________________________________________________

Capt. Ryan Dennison is the company commander of Echo Company, 2nd General Support Aviation Battalion, 135th Aviation Regiment. He holds a bachelor's degree in mechanical engineering from Rochester Institute of Technology and is a graduate of the Transportation Basic Officer Leader Course.

_____________________________________________________________________________________________________

This article was published in the July-August 2016 issue of Army Sustainment magazine.

Related Links:

Discuss This Article in milSuite

Browse July-August 2016 Magazine

Army Sustainment Magazine Archives

Social Sharing