ABERDEEN PROVING GROUND, Md. -- Scanning the globe for the latest technology is a continual process for the U.S. Department of Defense.

Since 1980, the Office of the Secretary of Defense has leveraged new and evolving technology through a program called Foreign Comparative Testing, or FCT. The program's mission is to find and assess "here and now" solutions -- wherever they originate -- to meet the operational needs of American service members.

In the last 12 years, enhanced body armor from Germany; a mine-clearing system from Denmark; and a bunker-busting, multi-purpose rocket warhead from Norway were a few of the 105 items tested and deployed by U.S. forces that originated in the FCT program. Other examples include advances in lightweight body armor and lighter, longer-lasting rechargeable batteries.

Jason Craley, FCT program manager with the U.S. Army Research, Development and Engineering Command, said a recent project will undoubtedly curry favor with service members.

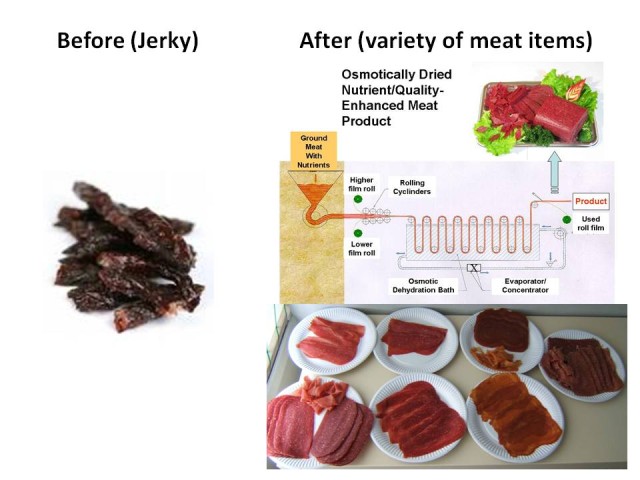

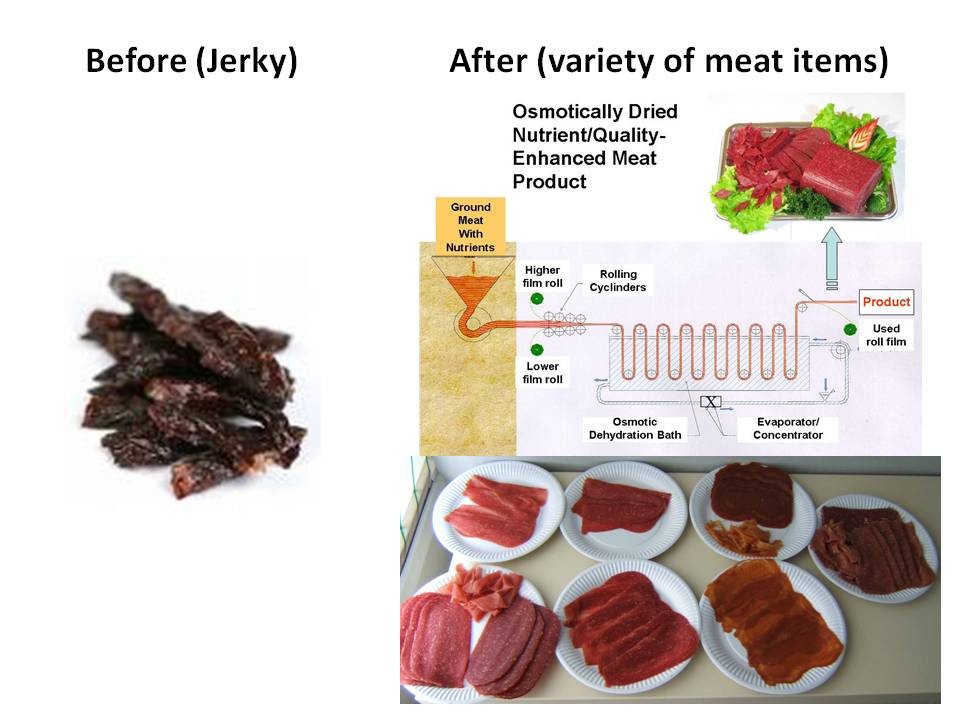

"One of the most welcomed improvements to date is a new method of processing meat rations that keeps beef and chicken as moist and tasty as anything in a local grocery store," Craley said, referring to the recently evaluated Osmofood system.

"It is a French-developed meat processing system that uses a unique drying process to produce a delicious, ready-to-eat meat that can last for at least three years at room temperature. With a greatly expanded menu and supplemental nutrients to improve cognitive and physical performance, Soldiers will get a much needed morale boost when this hits the field," Craley said.

"Meals, Ready to Eat will never be the same," said William "Randy" Everett, another member of RDECOM's International Technology Integration Team. "People may actually like them."

Craley said the Novel Processing System has yet another benefit- American jobs.

"As a result of this project a new product line incorporating the Osmofood drying process has been installed by Georgia-based FPL Food, LLC, at their food plant in West Columbia, S.C. As a subcontractor to Osmofood, FPL will meet all Army needs for the new meat rations from our own shores.

"The FCT program frequently opens the door to new opportunities like this for U.S. companies back home and the jobs follow. By leveraging Intellectual Property Transfer from foreign vendors, American companies can use FCT to position themselves as a key supplier to the Army while growing their businesses at the same time," Craley said.

By focusing solely on mature technologies, FCT acquisitions avoid the high costs associated with extended research and development. For example, the Novel Processing System for Ration Meat Items Project estimated that R&D costs to the government would have been $2 million to $3 million to develop a comparable capability from scratch, and would take at least 3 to 5 years to develop. By testing and incorporating the already mature French system, the Army avoided these upfront R&D costs and will begin supplying tastier meat to U.S. service members much sooner.

The FCT program has continually adapted to changing environments, Craley added.

"Prior to 1989 the program was referred to as the Foreign Weapons Evaluation and NATO Comparative Testing and focused initially on NATO allies," he said. "In 1989, the program was reborn as the Foreign Comparative Testing Program with authorization from Congress. At the end of the Cold War the program broadened its scope into countries such as Korea, Australia and South Africa which have supplied life-saving technology.

"The South African-developed Mine Protected Clearance Vehicle, or Buffalo, was successfully evaluated in 2002. It uses V-shaped hull technology to counteract roadside explosives. The timing for this could not have been better as the Buffalo would go on to be used extensively throughout Iraq and Afghanistan and save lives," Craley said.

"With the gradual withdrawal from Afghanistan and the DOD now facing a new age of fiscal austerity, the FCT program is meeting new challenges by promoting joint programs between the services and resource sharing. By doing more with less, the FCT program makes efficient use of taxpayer dollars," Craley added.

EVALUATE AND BUY

Despite a huge number of technologies to focus on, the OSD has one clear goal for the FCT program: evaluate and buy capabilities.

"The FCT program takes the best technology the world has to offer and puts it directly in the hands of our young men and women in the field. The program has been a tremendous asset to the Army and it has been a privilege for RDECOM to take the lead for our service," said Thomas Mulkern, leader of RDECOM's International Technology Integration Team that oversees the Army FCT program.

Each military branch and the U.S. Special Operations Command conduct FCT programs. Each nominates mature military or commercial products that provide a needed solution. Each service also conducts assessments and fields the technology when it is approved for acquisition.

Successes have been many, Craley said.

"Since its inception, 551 FCT projects from 28 countries have been completed. Considerations such as exportability and intellectual property limitations are considered upfront during the initial proposal submission process. Successful proposals that are selected for funding have a strategy in place to address problem areas and allow the U.S. military access to critical information once an item is fielded.

"The program is an example of how NATO and other foreign partners help satisfy U.S. technology requirements or help shore up operational deficiencies," he said.

Since the FCT program focuses on mature technologies, each project has accelerated acquisition. The program gets the world's best technology to the field fast, normally in less than 18 months, when compared with the typical acquisition process.

There's tremendous cost savings, too. The FCT program's estimated savings to U.S. research and development has been $7.6 billion over 30 years, Craley said.

An acceptable FCT project must have a high technology readiness level, which means that basic research and testing must have already been completed, and the capability has already been proven in a setting similar to what will be encountered in real-world operations.

COMPETITION IS FIERCE

Each year, OSD selects projects for funding.

"Competition is fierce, and only a few projects that meet strict criteria are selected," Craley said.

For Fiscal Year 2012 (Oct. 2011 to Sept. 2012), nine FCT proposals were initiated by the Army Comparative Technology Office. Only two were selected for funding.

Foreign vendors may initiate the FCT process by soliciting U.S. embassy support or they may also hire professional consultants to broker their business with the DOD. Members of the Comparative Technology Office from the DOD may attend international trade shows specifically looking for FCT candidates, Craley said.

For Fiscal Year 2012 the Army had two FCT projects that began in late January. Synopses for the two programs follow:

The Coating for Howitzer Breech Spindles project will apply advanced mature Physical Vapor Deposition, Electroless Ni, Superfinishing technologies to coat and refurbish 155mm Howitzer breech-spindles; analytical and firing tests conducted to validate the new process and prototype for transitions to production, replacing electroplated chrome, with improved durability, sustainability, environment benefits and at significant cost savings. This project will test and compare several coating and refurbishment technologies for the 155mm Howitzer-Breech Spindles. New coating technologies will mitigate wet and corrosion problems and extend the useful life of the spindles. The technology being evaluated originates from the United Kingdom, Germany, Switzerland and The Netherlands.

The Improved Aluminum Alloys for Armored Vehicles project will verify improved aluminum alloy armors currently approved for fielding on armored vehicles. These plates are possible candidates for use in Ground Combat Vehicle, the Joint Light Tactical Vehicle, and new production of foreign military sales M2 Bradleys. The technology being evaluated originates from Canada and Germany.

This year the Army is submitting five new FCT proposals to OSD. Selections are expected by July, and programs will start with the new fiscal year in October pending funding availability.

Social Sharing