PICATINNY ARSENAL, N.J. -- Red. Blue. Green. These aren't just colors, but they are indicators that show potential benefits to enhance the safety of U.S. warfighters.

Picatinny engineers are working on a new paint formula that will tell Soldiers if their ammunition is safe to use just by looking at the color.

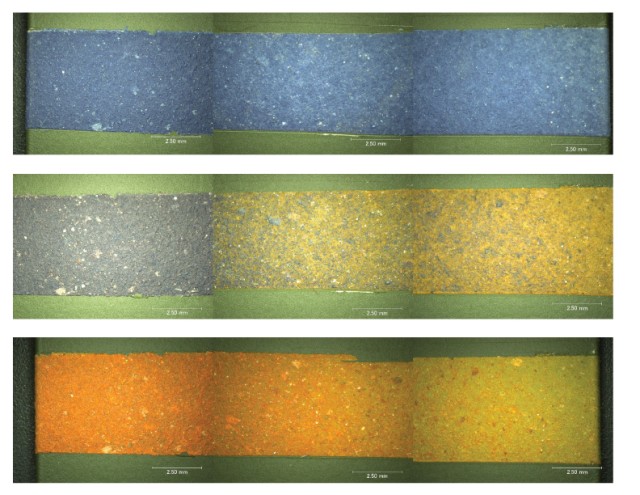

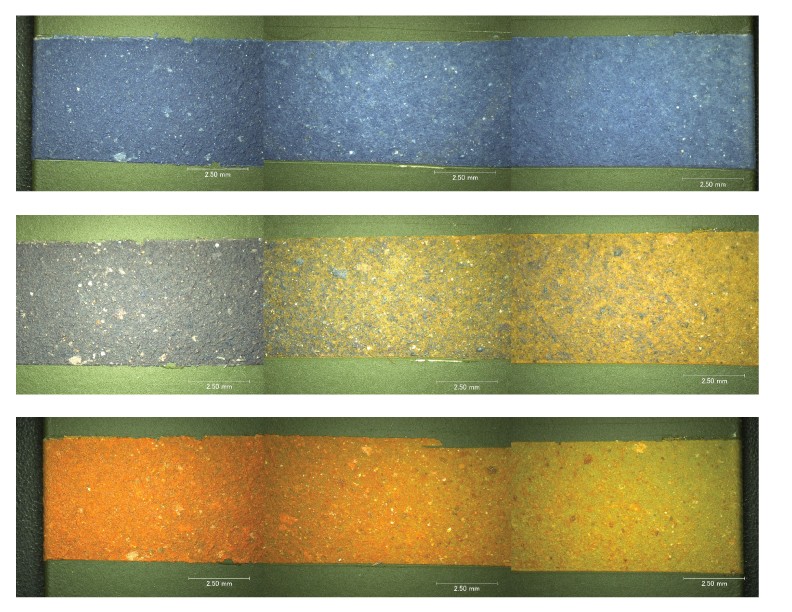

Referred to as Thermal Indicating Paints, this formula uses thermochromic polymers to detect temperature ranges that ammunition was exposed to during transport or storage.

A common example of a thermochromic object is a mood ring, which changes color in response to the body temperature of the wearer. The thermochromic element changes the wavelength of light when it is exposed to different temperatures.

The same basic concept applies to thermal indicating paints for ammunition, but Picatinny's challenge is ensuring the color change is permanent.

"We have formulas that change color within the designated temperature ranges, but our biggest challenge is maintaining long-term stability of a coating," said James Zunino, Project Officer / Materials Engineer, Armament Research, Development and Engineering Center (ARDEC). "We have to develop a paint that will survive in military operating conditions, including harsh temperatures and wind blasts."

Throughout combat operations, ammunition is often exposed to extreme temperatures during transport, storage and pre-positioning. Research shows that Middle East combat operations temperatures inside munition containers can exceed 190 degrees Fahrenheit. (Water boils at 212 degrees Fahrenheit under standard conditions at sea level.)

Storing ammunition at high temperatures can compromise the integrity and performance of the round. Moreover, using the overexposed round can increase safety risks for the warfighter.

When propelling charges are exposed to high temperatures for extended periods, it can rapidly deplete the propellant stabilizer, which creates a potential for auto-ignition. Additionally, if the overheated propellant is fired, it can lead to dangerous, elevated gun pressures that cause weapon failure and put the Soldier at risk of injury.

There have been documented incidents of failures caused by thermal exposures during Operation Desert Storm and recent conflicts in Iraq and Afghanistan.

"Thermal indicating paints can help prevent warfighters from using ammo that may have been compromised by exposure to environmental conditions outside of design limits," Zunino said. "It could reduce the amount of accidents that could happen, it can reduce the logistical burden of transporting and storing munitions, and it gives increased survivability to the Soldier."

ARDEC uses in-house testing equipment at Picatinny to test various formulations of the paints. The team is partnering with the New Jersey Institute of Technology to develop a formula that can provide an irreversible, permanent color change to indicate specific temperature ranges on munitions.

"Working with NJIT has been exceptional," said Giuseppe Di Benedetto, ARDEC Technical Lead / Chemical Engineer. "We work very closely with one another and we're actively meeting with them."

The team is developing cost effective and commercially available formulations that can detect four heat ranges: (degrees Fahrenheit) 145-164, 165-184, 185-200, and above 200. The first round to be tested will likely be the 30mm High Explosive (HE) round.

The paint coating has potential to cost less, as in pennies per application compared to costly temperature gauges the Army now uses on its larger caliber ammunition stocks.

"We're starting with the 30mm family of ammo, because they aren't expensive enough rounds to deem the use of a costly temperature gauge or monitor. The savings are bigger because it's low value, high volume assets," Zunino said, adding that the team plans to have a formula ready for trial testing within the year.

The Project Director Joint Services, a division of the Program Executive Office for Ammunition headquartered at Picatinny, manages the program and will coordinate the Army's acquisition and fielding efforts on the new paints.

"The desired outcome in the Class V (ammo) world would be a very inexpensive telltale that Soldiers and logisticians could use to identify munitions that had experienced temperature exposures outside design limits," said Mitch Hillard, Program Specialist, PD Joint Services.

"Such munitions could then be set aside for test and analysis to provide feedback to the development community on the performance and safety effects of extreme environmental exposures."

Thermal indicating paints are just one of many "smart" coatings the Picatinny team is developing for military applications. The team starting working on thermal indicating coatings in 2008 and has made considerable progress.

In the last year, they expanded the temperature ranges of the paints and added the capability to detect the period of time the munition was exposed to high temperatures. The length of exposure is determined by using a hand-held laser system, which causes changes in the optical reflectivity of the paint coating.

The team is also exploring non-military applications for thermal-indicating paints that can help firefighters, law enforcement personnel and first responders to emergencies.

Social Sharing