The spring 2025 edition of Army Sustainment contained an excellent article written by MG Gavin Lawrence and MG Michael Lalor titled “Transforming Army Sustainment Through Advanced Manufacturing.” Their article discussed recent challenges to the Army’s organic industrial base and how the U.S. Army Tank-Automotive and Armaments Command is aggressively working to solve supply shortfalls using advanced manufacturing at the Rock Island Arsenal–Joint Manufacturing and Technology Center (RIA-JMTC).

The purpose of this article is to share the initiatives that are now underway within the Ordnance Corps to increase the advanced manufacturing competencies of our 91E Allied Trades Specialists and the 914A Allied Trades Warrant Officers.

“Advanced manufacturing” is a broad term used to describe emerging technologies that leverage computer design and robotics to build parts through layers. The primary tools that Ordnance Soldiers use to manufacture parts are contained within the Metal Working and Machining Shop Set (MWMSS). The MWMSS consists of two expandable shelters that contain a variety of fabrication tools used for welding, plasma cutting, subtractive manufacturing using a lathe and mill, and additive manufacturing using a polymer 3D printer. The Army is also working to add a wire arc additive manufacturing (WAAM) capability to the MWMSS systems within allied trades sections located in the division sustainment brigades. The WAAM capability is a game changer because it enables the fabrication of parts without the need to haul massive amounts of metal stock across the battlefield. Allied trades specialists simply print the general shape of the part and then machine it with precision to the original part specifications.

Improving Enlisted Advanced Manufacturing Training

The first step that training developers took to improve advanced manufacturing was to assess our current training model to create a pathway for progressive education that increases with technical depth, beginning with advanced individual training (AIT) and then building on this foundation in the Advanced Leader Course (ALC). The current 91E Allied Trades Specialist AIT consists of 18 hours focused on additive manufacturing using the 3D printer. Students are trained to develop a 3D model of a repair part using computer-aided design (CAD) software that converts measurements into coding language.

Once the Soldiers develop a 3D model, the file is transferred to a different software program that breaks the 3D model into layers, enabling the 3D printer to build the part. When 91E Soldiers graduate from AIT, they understand the basics of 3D printing but still have a long way to go before they become experts.

Yet, as the Ordnance Corps looks to the future, training developers have added a substantial amount of additive manufacturing training to AIT, increasing it to 64 hours beginning in fiscal year (FY) 27. In addition, NCOs will also receive a significant increase in advanced manufacturing training. In previous years, ALC training focused on welding and subtractive manufacturing. Yet, the modernized FY26 course provides 229 hours of training focused on designing and fabricating repair parts using advanced manufacturing.

Enhancing Warrant Officer Advanced Manufacturing Training

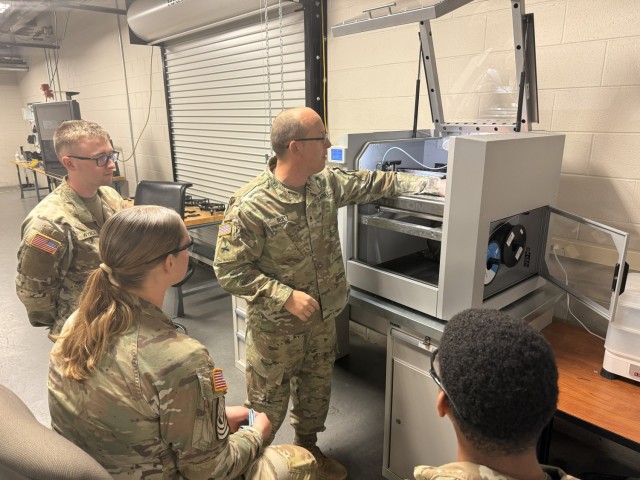

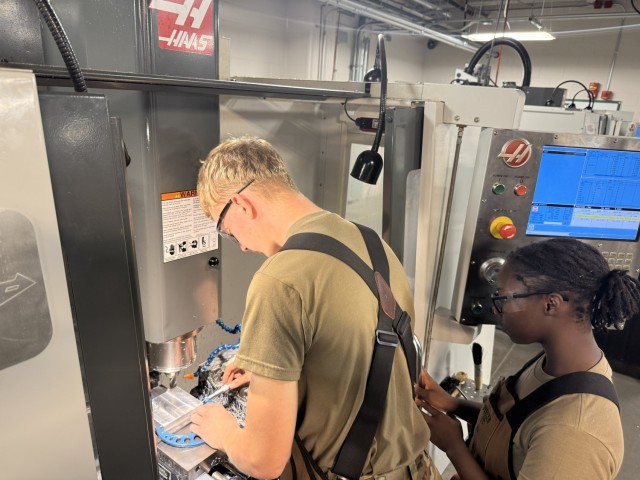

The 914A Allied Trades Warrant Officer is considered the expert in all things welding and advanced manufacturing and is responsible for supervising the allied trades personnel. The foundation to a 914A’s education begins at the Warrant Officer Basic Course where they receive 260 hours of advanced manufacturing training, which consists of 80 hours of additive manufacturing and an additional 180 hours of subtractive manufacturing using the mill and lathe. These warrant officers receive in-depth knowledge on designing parts in the CAD software, reverse engineering parts, creating slicer files for use in the 3D printer, and making the parts using computer numerical control (CNC) machining.

Yet, in FY26, the Ordnance Corps has significantly increased training in advanced manufacturing in the Warrant Officer Intermediate Course (WOIC) and the Warrant Officer Advanced Course (WOAC). WOIC students will receive an additional 216 hours of advanced manufacturing training using a full design-to-production cycle, beginning with the 3D model all the way to prototype validation. Additionally, WOAC students will receive another 300 hours of training in advanced manufacturing design concepts. This includes the integration of doctrine, standard operating procedures development, and several other projects, requiring students to draft complete advanced manufacturing work packages that include CAD models, repair plans, and parts production for non-standard/expedited repairs.

Ordnance Corps Partnership with RIA-JMTC

The Army’s Training with Industry (TWI) program is designed as a work-experience program that provides extensive exposure to industrial procedures within corporate America. The Ordnance Corps continually refines TWI partnerships to ensure warrant officers and NCOs acquire broadening experience and industry-standard technical skills to set them up for success in their follow-on assignment with the U.S. Army Combined Arms Support Command (CASCOM) as a capability developer, training developer, or instructor. Over the past decade, Lincoln Electric in Cleveland, Ohio, has led the warrant officers in training industry standards in welding technologies. Due to the emerging technologies of advanced manufacturing, the 45th Chief of Ordnance, COL Robin Montgomery, devised a new concept titled Training with Enterprise (TWE) as an opportunity for high-performing warrant officers to partner with the engineers and technicians in one of our Army depots.

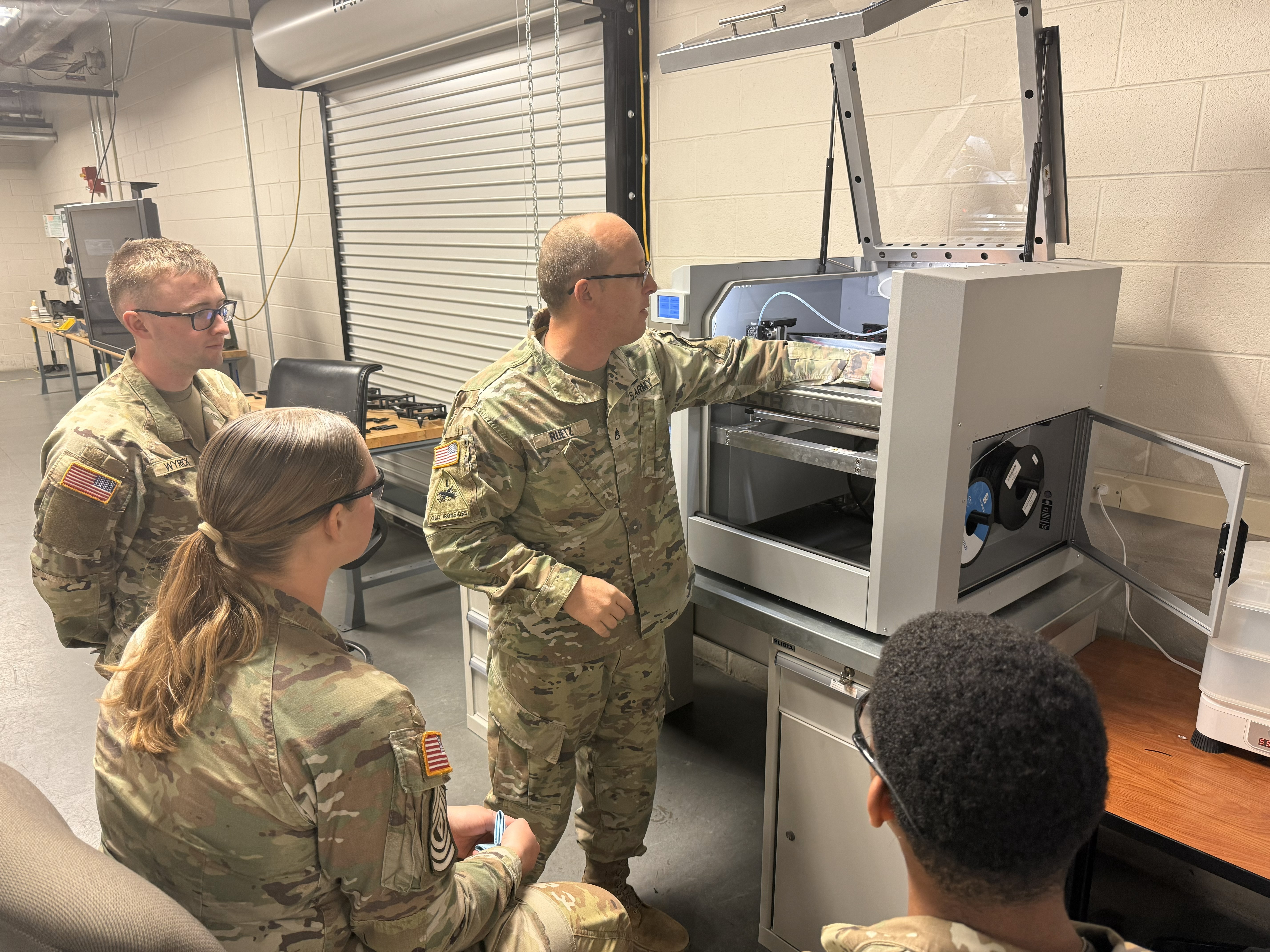

The first iteration of TWE was a two-week trial run conducted in July 2025 at RIA-JMTC and tailored for the 914A Allied Trades Warrant Officers. The schedule for the five selected warrant officers consisted of a tour of RIA-JMTC, an overview of the engineering process and build setup procedures, and several days of hands-on work with fused deposition modeling, multi-jet fusion, low plasticity burnishing, directed energy deposition, cold spray, additive friction stir deposition, and post processing. In addition, the warrant officers received vital instruction on assessing risk and determining parts candidates for advanced manufacturing to help them better advise commanders.

The five warrant officers came to this TWE event eager to learn and equipped with unique readiness challenges from their units. They were able to work alongside RIA-JMTC engineers to design and produce repair parts for non-mission-capable equipment in their units. One of these parts was a fuel shut-off arm for the M113A3 armored personnel carrier that causes frequent failures. They were able to take the original arm made of cast aluminum, conduct a 3D scan, transfer it to the CAD software, and manufacture the part using a laser powder bed fusion 3D printer. In a short time, the warrant officers were able to design and produce multiple parts that exceeded original equipment manufacturer specifications.

Conclusion

The future looks bright with the TWE partnership between the Ordnance Corps and RIA-JMTC. Beginning in the summer of 2026, the Ordnance Corps will send a 914A Allied Trades Warrant Officer to work at the Rock Island Arsenal for an entire year. The warrant officer will not only learn from the experts at RIA-JMTC but will also be the liaison between RIA-JMTC and 914As in the operating force. This linkage between the Ordnance Corps and RIA-JMTC will be vital to posturing the Army to leverage advanced manufacturing to fabricate parts at the point of need during large-scale combat operations. The lessons learned from the year spent at RIA-JMTC will be crucial to the follow-on assignment within CASCOM, enabling cutting edge capability development, doctrinal updates, training development, and instruction for the next generation of 91E Allied Trades Specialists and 914A Allied Trades Warrant Officers.

--------------------

CW5 Kent H. Shepherd III currently serves as the chief warrant officer of the Ordnance Corps. He oversees the accession, career development, and education of all Ordnance warrant officers in the Army. His most recent assignments were in U.S. Army Southern European Task Force G-4, 101st Airborne Division (Air Assault) G-4, and the U.S. Army Combat Readiness Center. His civilian education includes a Master of Arts degree in theology and church history from the Rawlings School of Divinity at Liberty University.

CW3 Justin Allen currently serves as the Allied Trades Warrant Officer training developer. He oversees the analysis and development of the Allied Trades Warrant Officer basic, intermediate, and advanced courses, and serves as subject matter expert to the allied trades enlisted training developers. He has a Master of Business Administration degree from Grand Canyon University and became a Certified Welding Inspector and Educator from the American Welding Society while attending the Training with Industry at Lincoln Electric.

--------------------

This article was published with the winter 2026 issue of Army Sustainment.

RELATED LINKS

The Current issue of Army Sustainment in pdf format

Current Army Sustainment Online Articles

Connect with Army Sustainment on LinkedIn

Connect with Army Sustainment on Facebook

-----------------------------------------------------------------------------------------------

Social Sharing