Introduction

Every warfighting function depends on logistics, but sustainment has always faced a time-distance problem. Commanders maneuver in hours while logisticians plan in days. By the time a logistics estimate is built, briefed, and disseminated, it risks being outdated. The Army’s current planning paradigm is anchored to the doctrinal days of supply (DOS) factor. DOS offers a useful baseline but fails to capture the demands of tailored, task-organized units fighting in large-scale combat operations (LSCO).

The Army’s Mercury logistics estimate tool is a major step forward for sustainment planning. It enables logisticians to generate demand forecasts for tailored unit configurations far more rapidly than manual staff work. A support operations (SPO) officer or unit S-4 can input the actual mix of personnel, vehicles, and weapons into Mercury and generate tailored sustainment estimates in minutes. Yet Mercury remains static. It depends on manual entry of unit data and produces a product that does not change unless the user re-runs the model. This is a critical limitation in LSCO.

The Army already has the data sources to close this gap. Global Combat Support System-Army (GCSS-Army) tracks equipment readiness and parts status. The Vantage platform, powered by Palantir, aggregates personnel and equipment readiness information across multiple Army enterprises. Additionally, the Maven Smart System (MSS) provides commanders with a dashboard for visualizing data feeds at echelon. What is missing is the integration.

This article argues for linking Mercury into Vantage, GCSS-Army, and Maven under the Army’s emerging C2 Next framework. By doing so, sustainers could move beyond static, doctrinal estimates to real-time, unit-specific demand forecasts. More important, Mercury could continuously update and publish logistics synchronization matrices (LOGSYNCMATs) inside Maven dashboards, providing commanders and staff with a shared, adaptive sustainment picture. With the addition of adaptive artificial intelligence (AI), Mercury could evolve from a calculator into a co-planner, anticipating requirements, recommending contingencies, and keeping sustainment aligned with operations in real time.

Mercury Today: A Tool for Tailored Estimates

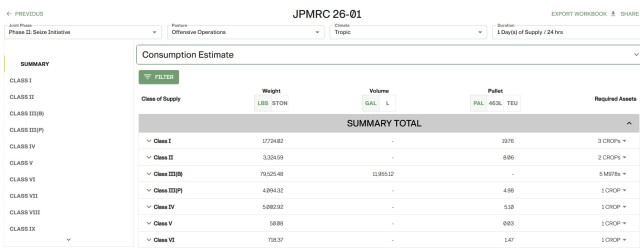

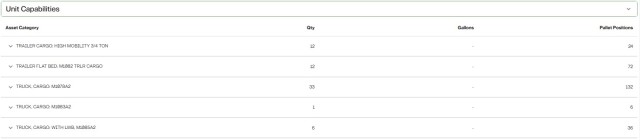

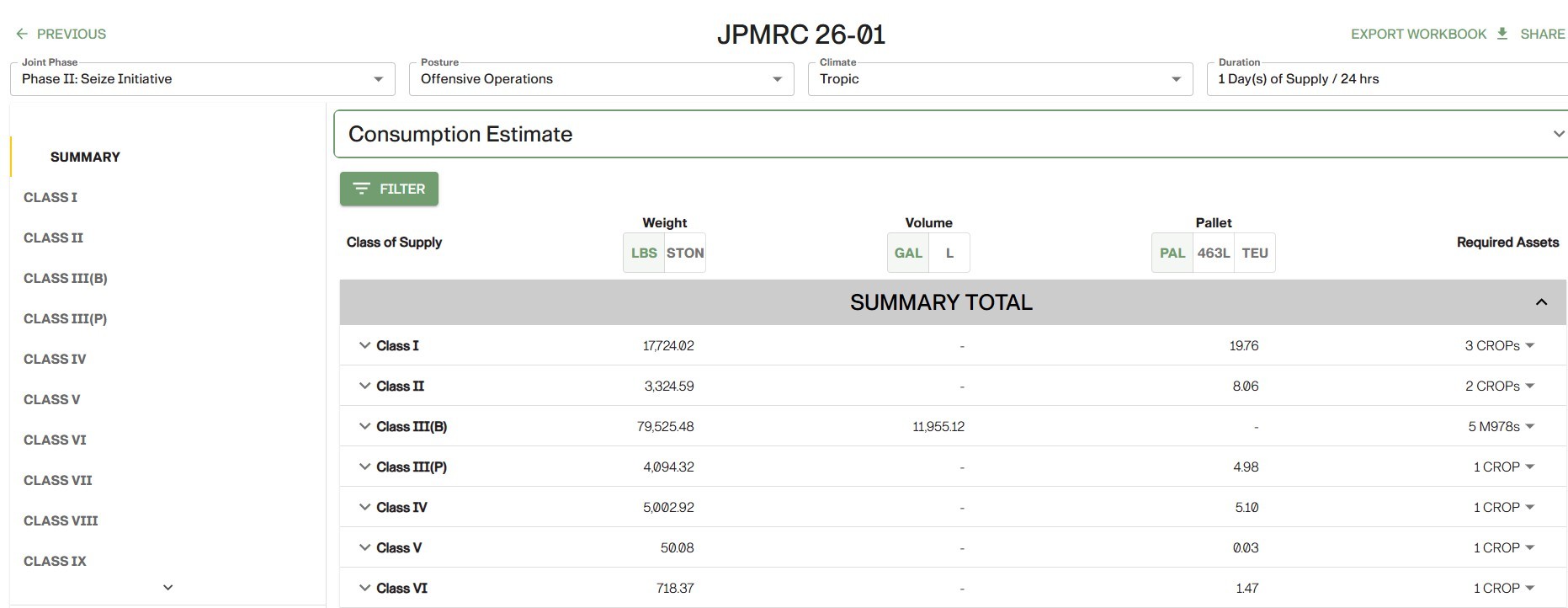

Mercury’s core strength is its ability to produce tailored sustainment estimates for units. Instead of relying on doctrinal averages, logisticians can input the actual mix of equipment and personnel into the tool to identify a fixed DOS for that unit. If an infantry battalion fields 30 Infantry Squad Vehicles (ISVs) instead of none or carries a drone fleet not accounted for in doctrine, Mercury can model those changes and produce refined estimates of Class III, V, and IX consumption. Commanders can see how attaching a High Mobility Artillery Rocket System (HIMARS) battery or armor company team changes the resupply requirement. SPO shops can compare multiple task organization options rapidly.

But Mercury is user dependent. The staff officer must manually enter personnel densities, weapon counts, and full mission capable (FMC) rates. This input process is laborious, prone to error, and quickly outdated. A logistics status (LOGSTAT) showing 90% FMC in the morning may be reduced to 70% by nightfall after combat losses. This manual dependence limits Mercury’s operational value. In LSCO, staff officers will be unable to keep pace with operations through manual updates.

The Gap: Static Products in a Dynamic Fight

Sustainment planning has always struggled with the gap between static estimates and dynamic realities. The LOGSYNCMAT, usually produced in Excel or PowerPoint, is meant to capture the intent of the sustainment fight by laying out when, where, and how units will receive resupply. But building that product can consume hours of staff time, and it is usually outdated by the time it is briefed. Every sustainer knows the frustration this creates. Fuel projections, for instance, may look sound on paper, only for a battalion to burn through Class III at a far higher rate than expected. A HIMARS battery that was expected to fire sparingly may suddenly have a surge of missions, spiking its Class V requirements.

In each of these cases, the static product sitting on the commander’s desk does not reflect the reality unfolding in the fight. Unless the staff rebuilds the plan from scratch, the LOGSYNCMAT remains a snapshot frozen in time while the battlefield moves on without it.

Maven as the Sustainment Dashboard

MSS offers a way to break this cycle, not as a logistics system but as a shared dashboard environment that pulls disparate data streams into one place. Its real power lies in visualization. Maven allows commanders and staff at every echelon to see the same information at the same time. For sustainment, this means Maven can serve as the home for a LOGSTAT workshop, where units input their consumption rates and stockage levels as they change throughout the day. Rather than waiting for a single roll-up each evening, updates flow continuously into the system.

The effect is profound. Stovepipes collapse. Reports are automatically aggregated across levels of command. Sustainers see a living reflection of the battlefield rather than a stale snapshot. Yet the strength of Maven — its ability to capture and display the flood of data — is also its limitation. Visualization alone does not turn information into action. The question remains: how do sustainers convert a stream of LOGSTAT updates into a coherent distribution plan? That is where Mercury enters the picture.

Linking Mercury to Vantage, GCSS-Army, and Maven

The next step is to connect Mercury to existing Army data systems. The concept is simple. GCSS-Army provides equipment readiness: on-hand counts, FMC status, and parts availability. Vantage provides personnel strength, duty status, and equipment readiness metrics. Maven provides live LOGSTAT inputs from units in the fight.

If Mercury could pull these data streams automatically, sustainers would no longer need to manually adjust unit densities. Mercury would continuously reflect the real composition of the unit: how many Soldiers are present for duty, how many vehicles and weapons are FMC, and what levels of supply are on hand. With that foundation, Mercury can combine unit readiness data with live LOGSTATs to recalculate demand and distribution requirements.

Reimagining the LOGSYNCMAT

The LOGSYNCMAT has long been the central tool for synchronizing sustainment. But it has always been manual, static, and quickly outdated. Integrating Mercury into Maven changes that.

In this model, units update LOGSTATs in Maven workshops. Mercury ingests those LOGSTATs, combines them with Vantage/GCSS-Army data, and recalculates requirements. Mercury generates an updated LOGSYNCMAT automatically. The LOGSYNCMAT is published back into Maven, visible to all commanders and staff.

The LOGSYNCMAT thus becomes a living product, updated continuously as conditions change. Commanders can see in real time when resupply is triggered, when it is projected to arrive, and how future operations will be impacted.

Adaptive AI: Mercury’s Future Potential

Mercury today is a powerful calculator, but its true potential lies in becoming something more. At present, it does not employ AI, yet the Army must look toward a future where adaptive AI is woven into its design. With AI, Mercury could evolve from a tool that merely tabulates requirements into one that anticipates problems and recommends solutions. This matters because anticipation is at the very heart of sustainment. In LSCO, demand rarely follows neat, linear patterns. Adaptive AI would allow Mercury to recognize those nonlinear trends and project their impact on the distribution plan before shortages materialize. As updated LOGSTATs flowed in through Maven, Mercury could immediately adjust the sustainment estimate and rebuild the LOGSYNCMAT.

Such a system would also strengthen continuity and economy of effort. By pulling live data from Vantage and GCSS-Army, Mercury would ensure the LOGSYNCMAT reflects real personnel counts, FMC rates, and on-hand equipment, removing the guesswork and manual manipulation that bogs down staff work today. Resupply missions would be prioritized and sequenced in a way that avoided waste. In practice, commanders would no longer operate on assumptions; they would see a distribution plan based on reality, continuously updated and displayed in Maven alongside the operational picture. In this role, Mercury would become a co-planner. It would process the raw data of readiness and LOGSTAT reporting, transforming it into an actionable distribution plan and ensuring the plan would always be current. AI would accelerate the sustainment cycle of anticipate, decide, and act. Human logisticians would remain central, however, because they would validate the outputs, refine the details, and bring improvisation when the unexpected occurred.

A Pacific Vignette: Resupplying the Philippine Batanes Islands

Imagine a division task force spread across the Batanes Islands of the northern Luzon in the Philippines. On the island of Itbayat, an infantry battalion is burning fuel at a far higher rate than projected. At the same time, on the nearby island of Basco, a company has just lost several vehicles to enemy drone strikes. That sudden loss has changed both its Class IX repair part requirements and its Class III fuel profile almost overnight. In the current sustainment paradigm, these changes might take 12 to 24 hours to filter up into the division’s sustainment plan, if they appear at all.

With Mercury integrated into Maven, however, the story unfolds differently. Units on both islands update their LOGSTATs directly through a dashboard workshop visible to every echelon. At the same time, GCSS-Army and Vantage feed live data on FMC vehicles and personnel status directly into Mercury. Mercury automatically recalculates demand based on this combined picture and generates a revised LOGSYNCMAT. Within minutes, Maven publishes the updated matrix across the division, showing commanders that rotary-wing resupply missions must now prioritize Itbayat’s accelerated fuel burn while redirecting Class IX repair parts to Basco.

C2 Next: The Convergence Point

The Army’s C2 Next initiative envisions a data-centric command and control framework where all warfighting functions converge on a shared data environment. Sustainment cannot remain siloed. Linking Mercury to Vantage, GCSS-Army, and Maven would place sustainment data inside the same decision environment as operations.

Three decisive effects would emerge: All echelons would see the same sustainment reality. There would be no more mismatched estimates between battalion, brigade, and division. Commanders would act on continuously updated sustainment forecasts instead of 24-hour-old rollups. Sustainment plans would adapt in stride with maneuver.

Implementation Pathway

Achieving this vision of Mercury as a continuously updated sustainment engine within C2 Next will not happen automatically. It requires deliberate investment, organizational change, and doctrinal adjustment. Five steps in particular, all achievable, stand out as essential to transforming Mercury into a fully integrated decision-support system.

- Integrate Data Feeds — The first and most critical step is building the technical connections that would allow Mercury to pull from GCSS-Army, Vantage, and Maven. Sustainment planning is only as good as the data it draws from, and right now Mercury depends on manual entry. By automating data feeds, the system would continuously ingest equipment status, FMC rates, personnel counts, and LOGSTAT updates without human intermediaries.

- Embed LOGSTAT Workshops in Maven — The second step is to standardize how units submit their status reports by embedding LOGSTAT workshops directly into Maven dashboards. Instead of nightly roll-ups or ad hoc reporting formats, every echelon would input consumption, stockage, and requirements through a common interface visible across the formation.

- Develop AI Modules — Once the data foundation is secure, Mercury must evolve with adaptive AI modules designed specifically for sustainment. These modules would not replace logisticians but would amplify their ability to anticipate and respond. For example, AI could forecast nonlinear changes in demand when operational tempo increases, highlight emerging shortages before they reach crisis, or recommend adjustments to the LOGSYNCMAT based on new LOGSTATs.

- Train Logisticians — The Army must educate logisticians at every echelon on how to supervise, validate, and refine AI-enabled outputs. This does not mean abandoning traditional staff skills. SPOs will still need to understand how to build estimates manually, but it does mean shifting the emphasis from creating products to interpreting and adjusting them.

- Experiment in Exercises — The Army must deliberately experiment with Mercury-enabled sustainment at combat training centers, during Joint Pacific Multinational Readiness Center rotations, and in major bilateral/trilateral exercises like Yama Sakura. These environments offer the perfect laboratories to stress-test the system in conditions that replicate LSCO, including communications degradation, enemy interdiction, and the friction that comes with maneuver.

Conclusion

The Army can unlock Mercury’s true potential by linking it directly to Vantage and GCSS-Army for live personnel and equipment readiness data, to Maven for continuous LOGSTAT inputs, and by publishing updated LOGSYNCMATs back into Maven dashboards for all commanders to see.

The impact of this integration would not just technical but also operational. Commanders would gain a sustainment picture that would no longer be a snapshot but a living reflection of the fight. Mercury would become an engine that would not only processes data but would also highlight anomalies, forecasts shortfalls, and recommends adjustments to the distribution plan in stride with operations. Human logisticians would remain indispensable. They would bring judgment, creativity, and improvisation that no machine can replicate, but AI would ensure that the sustainment enterprise would keep pace with the tempo of maneuver.

In LSCO, where complexity, dispersion, and contested communications can overwhelm static planning, this capability could prove decisive. The side that adapts its logistics picture the fastest will win. By investing in Mercury’s integration under C2 Next, the Army can ensure we are the side that wins.

--------------------

MAJ Sean McLachlan is the deputy G-4 for the 25th Infantry Division and formerly the support operations officer for the 225th Light Support Battalion, 2nd Light Brigade Combat Team, 25th Infantry Division. He has master’s degrees in military history from Norwich University and the U.S. Army Command and General Staff College and is a Ph.D. candidate at Liberty University. He is the winner of the 2024 LTG Arthur Gregg Sustainment Leadership Award and the Transportation Corps Field Grade Officer of the Year.

--------------------

This article was published in the winter 2026 issue of Army Sustainment.

RELATED LINKS

The Current issue of Army Sustainment in pdf format

Current Army Sustainment Online Articles

Connect with Army Sustainment on LinkedIn

Connect with Army Sustainment on Facebook

-----------------------------------------------------------------------------------------

Social Sharing