As the “Home of Army Aviation,” Fort Novosel is an incredibly busy place. The number of flights there represent 32% of the Army’s total flying hours and in 2022 alone there were 2 million takeoffs and landings at the Alabama installation.

To put that into context, the traffic count at Atlanta’s Hartsfield-Jackson International Airport – consistently counted among the nation’s busiest – is less than half of that at Fort Novosel, which provides air and ground training for Army rotary wing pilots using a fleet of 547 aircraft.

“To keep things running efficiently and meet the training mission, our Environmental Team has to manage the extensive maintenance as well as the waste streams from fuels, hazardous materials and other hazardous waste that come from managing such a large and active fleet,” said Julie Majors, Fort Novosel Physical Scientist. “For example, we have fuel storage capacity of more than 1.6 million gallons and an annual throughput of more than 20 million gallons per year.”

With that level of activity and the nature of handling fuel and other waste issues, it would be natural to assume that during its 24-hour-a-day operation there would be some mistakes leading to compliance issues. That is not the case, said Melissa Lowlavar, Fort Novosel Environmental and Natural Resources Division Chief.

“In that last year, Fort Novosel received no notices of violation from regulators and in the installation’s history has only received one NOV,” Lowlavar said. “By committing to environmental guidance and support and ensuring all installation organizations are trained and doing their part to remain in compliance, we’ve built a culture that has produced an exemplary record that we are all proud of.”

One reason for the remarkable record of success at Fort Novosel is the use of technology to share information, streamline processes and make accessible the tools needed to run an efficient, effective and environmentally conscious operation.

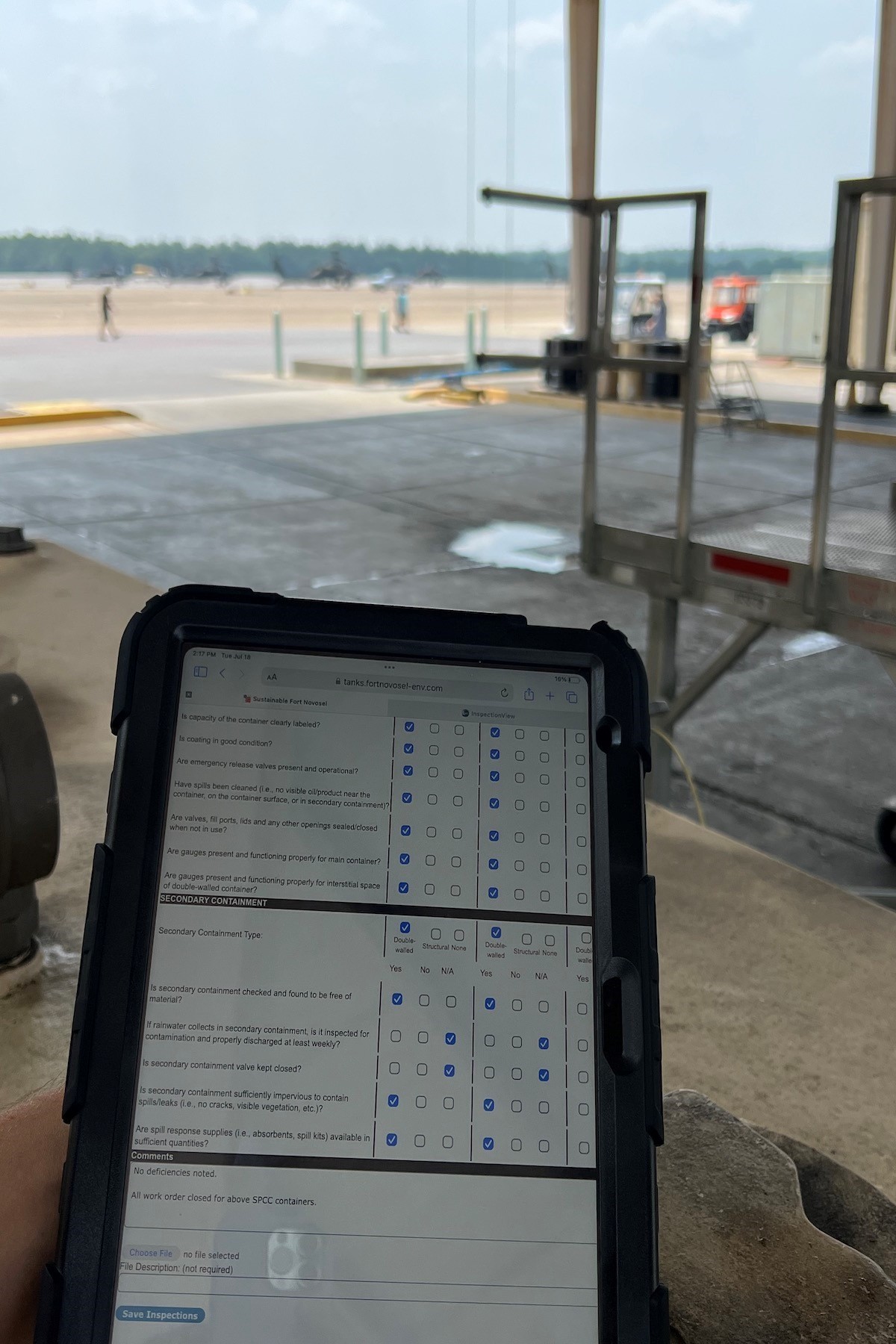

A prime example of this approach in action is the “Sustainable Fort Novosel” website, which the team refers to as a one-stop-shop for all things environmental at the installation. The team created 27 forms, each of which is associated with different environmental plans and programs. To supplement this, the team also created 21 specific work instruction documents which identify what is required of personnel that support storage tanks, wash racks, hazardous materials and waste and other programs.

“The website is a valuable resource at Fort Novosel and is now frequently used to share information across the Army,” said Susan Cowart, Fort Novosel Environmental Scientist. “This kind of collaboration and sharing of on-point information not only saves time and money, it helps to promote a culture of environmental compliance throughout the Army.”

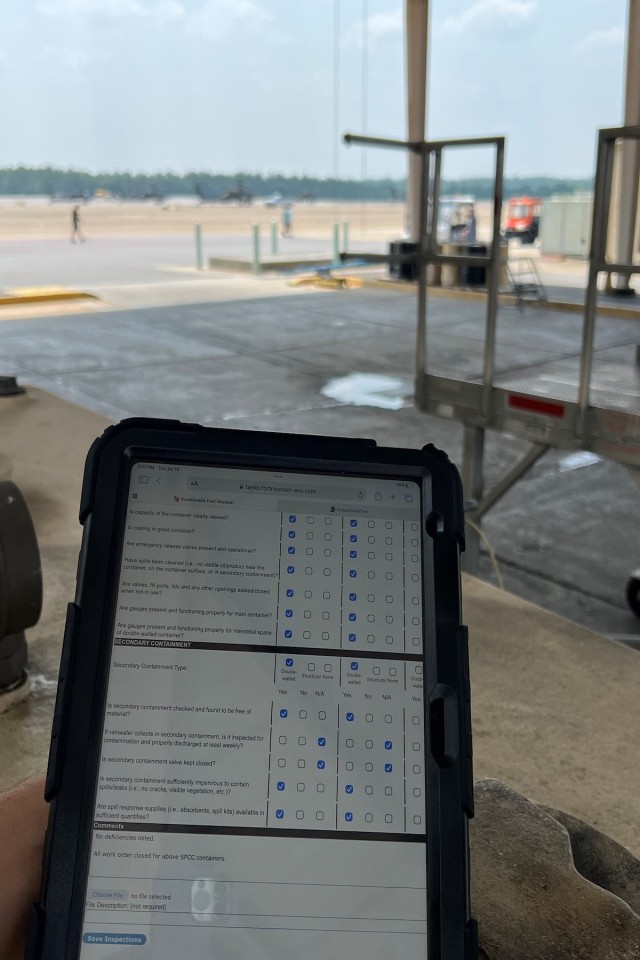

In addition to sharing information, the team also conducts more than 30 internal “no-notice” compliance inspections each quarter, using detailed checklists that totals 43 pages and covers oil and material storage including hazardous waste storage, wash racks, universal waste, solid waste, construction stormwater, industrial storm water and more.

The inspections are conducted and recorded using digital tablets, which allows inspectors to easily add photographs to the reports. The reports are downloaded to an Internet site, giving the team immediate access to the data and saving time and reducing paper waste.

“Fort Novosel is leading the way in using modern technology to improve the inspection process,” said Allison Marshall, Fort Novosel Environmental Scientist. “The team conducted more than 240 internal compliance inspections during the 2-year awards period to ensure that the installation’s organizations have a clear understanding of what is required to maintain regulatory compliance.”

Fort Novosel’s Environmental Team has also created a digital newsletter sharing environmental and compliance information, has partnered with multiple organizations on sustainability and natural resources projects. Additionally, the team helped lead a recycling effort that included extensive community outreach as part of overall recycling at the installation that is estimated to have saved more than $450,000 in disposal costs last year.

“Fort Novosel, thanks in large part to the work of the Environmental Team, has stepped up to meet the environmental challenges it faces in maintaining its critical training mission,” said Lowlavar. “Through extensive training, a robust self-inspection program, an innovative and practical website, and through partnerships with regulators and conservationists, Fort Novosel has set itself apart to lead the Department of Defense now and into the future.”

Social Sharing