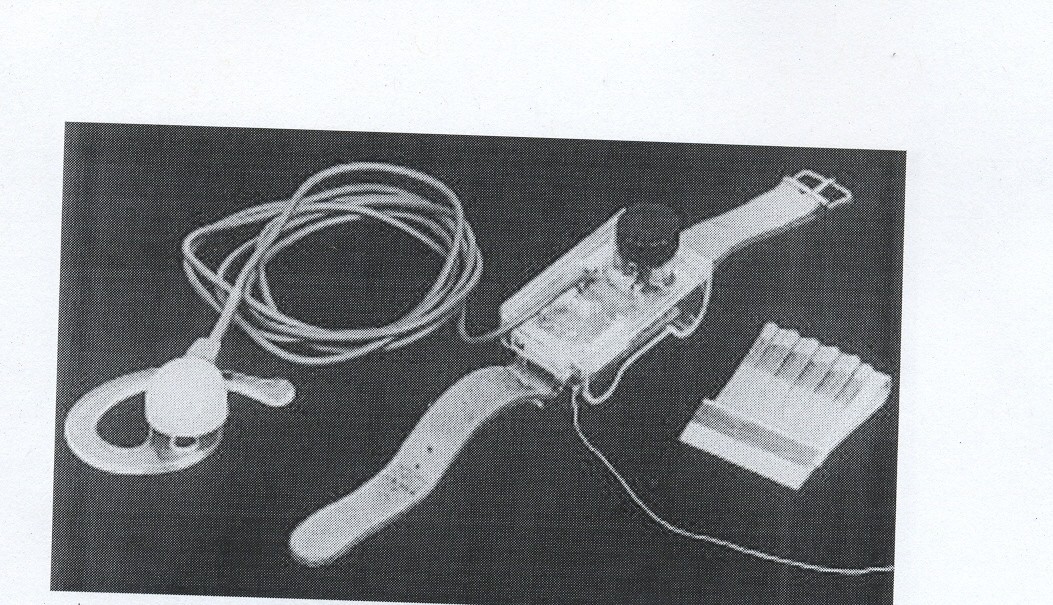

We’re accustomed to having the power of communications and computing in the palm of our hand, but 70 years ago, developing equipment small enough to carry and conceal was something that seemed possible only in comics. In September 1953, newspaper articles proclaimed the work of the Signal Corps Laboratories in developing a miniature radio that could be worn as a wristwatch, called the “Dick Tracy.” The radio had a receiving range of 40 miles and weighed in at two and five-eighths ounces. A wire connected the wrist-worn receiver with a small in-ear amplifier, which could be threaded through the wearer’s sleeve to make it worthy of the best fictional spy-gear.

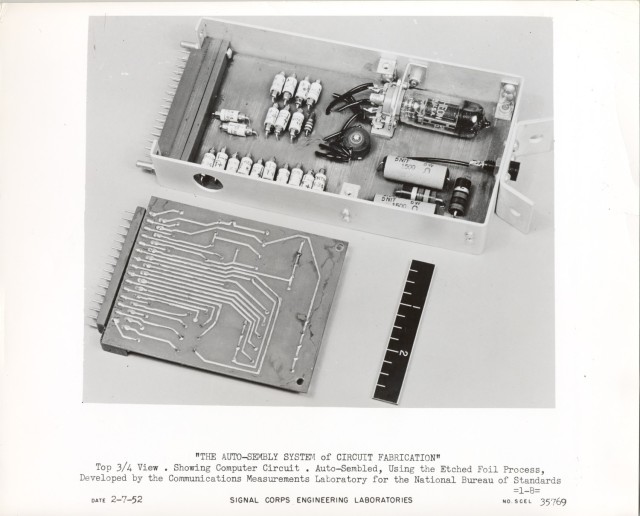

The technology that made this possible was the result of a long-term developmental process at the Signal Corps Labs and then the U.S. Army Electronics Command, the forerunners of today’s U.S. Army Communications-Electronics Command, which focused on miniaturization and micro-miniaturization of electronics for the U.S. Army. Documented in the 1966 ECOM historical monograph, “Miniaturization and Micro-miniaturization of Army Communications-Electronics, 1946-1964,” the development of the interwoven technical areas of printed wiring, transistors, and integrated circuits paralleled and complemented each other. The invention of dip-soldered printed wiring in the Signal Corps in 1948 aroused the interest of the electronic industry in this new concept of construction and led to the first practical, mechanized, electronic production lines in the United States. The almost simultaneous invention of the transistor by the Bell Telephone Laboratories in 1948 spurred the subsequent creation by the Signal Corps of entirely new families of compatible miniature electronic parts, transistors, and diodes which, together with printed wiring, made possible still newer levels of miniaturization achievement in the 1950s.

Before World War II military electronic equipment design in the United States was strongly dominated by cost. Miniaturization was incidental, occurring fortuitously with smaller electronic parts when and if they became available. The parts’ designers, sharing this philosophy, relied on the development of new materials for progress in miniaturization; the materials were in the hands of chemists, physicists, and metallurgists, few of whom were concerned particularly with the development of smaller electronic devices.

Miniaturization as a major design goal in communications electronics equipment began to be felt only after the requirements of the Armed Forces began to be impressed on industry after World War II. Adequacy for combat service in many cases was 'so dependent on size that miniaturization had to be employed regardless of cost. Even then, a paucity of suitable parts and the absence of any vigorous programs for their development hampered early efforts.

In the postwar summary and analysis of its cumulative war experiences with the strengths· and weaknesses of field electronics, the Signal Corps Engineering Laboratories, established several firm reference points from which Army research and development could set new objectives for its next generation of electronic equipment. Reports received during and after the war cited the fact that Army electronics was grossly deficient in its resistance to fungus, moisture, and corrosion in jungle and other hot and humid environments. It was clear, too, that the rigors of the battlefield demanded much sturdier electronics that could take the physical punishment of shock, vibration, temperature change, and weather.

SCEL development personnel were also convinced that the size and bulk of Army electronics had to shrink, particularly in the portable and vehicular categories. This miniaturization requirement assumed major importance in the light of the anticipated postwar expansion of electronics as the principal medium of communication, surveillance, fire control, countermeasures, intelligence service, meteorological soundings, and other such areas. In 1946, an ad hoc committee reported that "miniaturization should and will be a major objective in the design of future Signal Corps' equipment."

The postwar appraisals set the stage for the Signal Corps’ efforts regarding miniaturization. It was in these early programs that new device concepts and technologies were born which were to revolutionize the arts of electronic equipment construction not only in the U. S. Army, but in the entire electronic industry. In the 10-year period from 1946 to 1956, came the miniature glass capacitor, the ruggedized meter, arctic cables, reliable relays, new waveguide components, improved radio frequency cables, miniature connectors, ruggedized tubes, new tropical treatments of equipment, longer lived batteries, dip-soldered printed circuits, new transistor technologies and devices, and dozens of other innovations and replacements that became established production-line products for the new generation of military systems in the 1950s and 1960s. These efforts lead not only to novelty items such as the Dick Tracy watch-radio, but had a direct impact on making possible the hand-held electronics that we use in our everyday lives.

Social Sharing