ROCK ISLAND ARSENAL, Ill. – The U.S. Army Sustainment Command’s critical role in the former Operation Warp Speed came to an end Feb. 28 as the last trailer used in clinical research was closed.

This trailer was in Hays, Kansas, at the Kansas State Agricultural Research Center, marking the final end of an ongoing demobilization.

Specifically, it was ASC’s Logistics Civil Augmentation Program or LOGCAP that contributed to the success of this historic venture to produce vaccines in record time to fight the Coronavirus and save untold lives.

LOGCAP is best known for setting up and maintaining base camps over the past two decades in Iraq, Afghanistan, and other areas where U.S. military is deployed. In times of emergencies, such as hurricane devastation, LOGCAP has been tasked to support domestic and international operations.

Gen. Gus Perna, then-chief operating officer for Operation Warp Speed, and former commanding general of the U.S. Army Materiel Command, ASC’s higher headquarters, called upon LOGCAP to provide COVID-19 testing support shortly after the mission took shape in the early months of the pandemic.

“LOGCAP provided us both speed and flexibility to provide safe and efficient testing accommodations at the appropriate scale,” Perna said back then. “Even as we begin to deliver vaccines, clinical trials will continue to play an important role for some time to come.”

ASC, specifically LOGCAP, is among the only entities with enough of a logistical reach to handle a job of this size and complexity, said Matt Meenan, a logistical management specialist and LOGCAP planner, and part of the LOGCAP project management team.

“The mission required a public-private partnership, and LOGCAP already had a global network and relationships with a variety of vendors,” Meenan explained. “Also, I believe ASC was picked because our leaders effectively presented the requiring activity with an explanation of what we do here. If the Army is involved and logistics support is required, some phones in Rock Island are probably going to ring.”

Meenan added choosing LOGCAP was a testament to the effectiveness and flexibility of the program.

“The reason they entrusted the program with such a unique and critical mission is because LOGCAP has proven, time and time again, that it’s up to the challenge,” he said.

Overall, LOGCAP set up 163 trailers in 69 locations coast to coast to provide facilities in the testing of various vaccines.

“LOGCAP installs and sustains temporary structures and facilities all over the world. As a principal Army tool for crisis management, LOGCAP’s ‘business as usual’ is to provide solutions fast,” Meenan said. “The governing documents and relationships we already have in place allow very fast response time to a variety of needs. This mission was just one of those needs.”

Meenan’s colleague, Steven Wall, a logistics management specialist and a senior LOGCAP planner also part of the LOGCAP project management team, said teamwork defined success.

“This event was successful because we were able to define and refine requirements almost daily to meet the medical requirements, and health, engineering and construction standards to install trailers,” Wall said, praising Army Contracting Command-Rock Island for its expertise and flexibility in accommodating these changes.

Hence, on May 15, 2020, then-President Donald Trump announced Operation Warp Speed, which had been directing the U.S. to develop vaccines to fight the fatal COVID-19 that was spreading globally in late 2019/early 2020. The name refers to faster-than-light travel, as portrayed in the Star Trek fictional universe.

It was renamed Countermeasures Acceleration Group or CAG by a presidential directive in 2021.

According to the Department of Health and Human Services' fact sheet, the goal of Operation Warp Speed was to "produce and deliver 300 million doses of safe and effective vaccines with the initial doses available by January 2021, as part of a broader strategy to accelerate the development, manufacturing, and distribution of COVID-19 vaccines, therapeutics, and diagnostics.”

The severity of the virus forced the world’s leaders to take unprecedented action, directing medical professionals and scientists to develop vaccines in record time. Such a monumental effort had never been undertaken regarding vaccination.

ASC’s global military logistics expertise was used to rapidly deploy specialized trailers fitted to meet specific requirements set by the HHS, said Brian Almonrode, director of operations and lead for ASC’s LOGCAP.

“While the medical aspect of the mission had never been done before, it was really just ‘work’ from a LOGCAP perspective. We know how to create requirements for temporary facilities and services to keep them running, because that’s what we do all over the world,” explained Almonrode.

“The uniqueness of the mission was our work with non-military personnel, specifically medical professionals, and municipal governments. But LOGCAP is flexible and customizable enough to support this new mission with a very short learning curve,” he said.

LOGCAP’s personnel quickly grasped the gravity of the mission.

“Terror, absolute fear of failure,” is how Wall described his initial reaction.

“However, ASC leadership provided a great culture of risk acceptance, administrative support, and daily assurance we were doing the right things with our contractors, contracting, and made available to us all the teammates we asked for and supported us. How could we not be successful,” he said.

“The logistics capability in Line of Effort 2 is not limited to organic AMC/ASC personnel and equipment. It also includes every capability in the service contract portfolio – in this case our contractor partners supporting LOGCAP,” said John Wyrwas, a logistics management specialist and senior LOGCAP planner, and LOGCAP Northern Command branch chief.

ASC has three Lines of Effort regarding its mission. LOE 2 is Enterprise Logistics Support with examples being it supports global operations, contracting support, and second destination transportation.

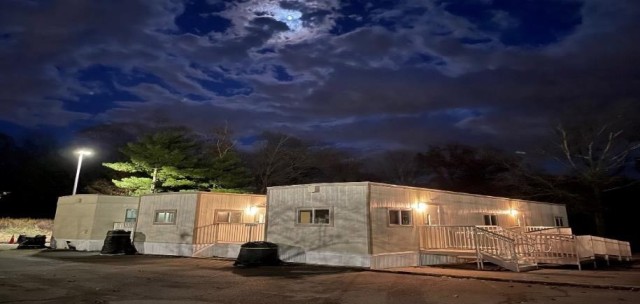

ASC’s contracted personnel were tasked with setting up and maintaining trailers where clinical trials would be conducted. In most cases, the trailers were set up near existing medical clinics, though others were stand-alone facilities.

“It didn’t seem too daunting when the requirements for the first clinical trial came in. When the second and third trials came in rapid succession it changed to, ‘Wow, this is huge,’” Wyrwas said.

“But we knew our team was up to the challenge having responded to other short notice, complex requirements like the COVID quarantine locations at various Army Installations across the country and the auxiliary hospital space for COVID patients built at New Bridge Medical Center in Paramus, New Jersey. We had confidence in our team here in the Program Management Office, our teammates in the AFSBs [Army Field Support Brigades], and the contractors supporting the program,” he said.

Some trailers remained in place for up to two years as clinical trials continued, with follow-up examinations even after vaccines were given to the general public.

While most clinical trials have about 3,000 volunteers, each of OWS/CAG’s vaccine candidate manufacturers expanded trials to include 30,000 people.

The initial set up began in July 2020 for four pharmaceutical companies conducting clinical trials: AstraZeneca, Janssen, Moderna, and Sanofi Pasteur.

The overall budget for the clinical facility project was $111 million, Almonrode said, which came from congressional approved funds.

Additionally, other parts of ASC and Rock Island Arsenal also supported to LOGCAP’s success: ACC-RI; Defense Contract Management Agency; LOGCAP Support Brigade; Army Corps of Engineers; contracted companies; the 404th, 406th, and 407th Army Field Support Brigades; Acquisition Integration and Management Center’s Enhanced Army Global Logistics Enterprise; Small Business offices; ASC’s G8 (Resource Management); ASC’s G6 (Information Management); General Staff Administration Team, ASC’s Legal office, and Command Surgeon.

CAG, however, is not over, Almonrode said, as certain aspects of vaccine trials continue.

“The CAG leadership approved a DoD-only extension to the Astra Zeneca trials at Forts Belvoir (Virginia) and Fort Sam Houston (Texas) along with Lackland Airforce Base (Texas). Moderna and Janssen trials had completed mid-summer 2022. LOGCAP sustained the three sites until completion of their period of performance,” he explained.

The process of ending its CAG mission wasn’t simply a matter of work stoppage, Almonrode said.

“Demobilization of non-DoD property required the LOGCAP team to learn the Department of Homeland Security and Department of Health and Human Services property system and modify our normal processes. While not difficult – just different,” Almonrode said.

The trailers and related equipment have been repurposed for other HHS needs, he said, such as for Native American health care, non-profit hospitals, veterans’ hospitals and a community healthcare center with over 100 trailers fully equipped with laboratory equipment and patient exam rooms.

“We often joke that we were ‘saving the world’ … I feel like the vaccines and their creators did the world a great service,” Meenan said.

Wyrwas said the feeling was one accomplishment once the vaccines were created.

“We knew that the increased capacity we provided to the clinical trial sties contributed to the unprecedented speed at which the vaccines were made available to the public. We knew we were part of a history making effort,” he said.

While the U.S. has now learned how to manage COVID-19, it’s only a matter of time before another similar pandemic arises as many healthcare professionals and scientists have said during the last couple of years. If and when that happens, ASC will be ready to assist with its newfound experience and lessons learned.

“The lesson, always remain flexible in decision making; be ready to adjust from a plan; and communicate what actions and decisions were made and why to everyone for a common understanding to keep the program moving forward to meet its mission/intent,” said Wall.

“Never look for blame, seek solutions. Understand how we got to this point, acknowledge the mistake, correct, and make the next plan work better from the failure, and don't repeat it,” he said.

And, Meenan said he too learned a lot.

“I learned the power of collaboration. Also, I learned that effective communication, flexibility, and understanding are vital for us to solve hard problems. Our Army work is often very directive – we give and receive orders, and actions follow accordingly. That doesn’t work outside the chain of command. We had to convince municipal governments, property managers and other non-military personnel that what we were doing was important and worthy of their support,” he said.

Likewise, Almonrode offered this.

“Deliver capabilities through logistical principles and focus on the execution of logistical contracted services that enable medical services/mission,” Almonrode explained. “LOGCAP is not the best tool for medical services; however, we can provide everything else medical professionals need to provide care.”

(Editor’s note: Paul Levesque, ASC Public Affairs, contributed to this article. Levesque is now retired.)

Social Sharing