for issue on June 27, 2019, at the Army Prepositioned Stocks-5 remote lot, Camp Arifjan, Kuwait. VIEW ORIGINAL

The fiscal benefits the Army and all military services realize in exercising economies of scale to stockpile prepositioned war reserve materiel (PWRM), Army prepositioned stocks (APS), and munitions are a strategic risk in the current global environment—especially in large-scale combat operations (LSCO). Consolidated stockpiles that are both mal-positioned and within range of enemy long-range fires can imperil the Army’s ability to rapidly deploy and penetrate adversaries’ anti-access and area denial (A2AD) systems as described in the multi-domain operations (MDO) concept. Compounded by adversarial long-range fires capabilities, near-peer competition through contested, access-denied areas has significantly complicated the calculus of how and where to deploy crisis response forces to create dilemmas for our enemies and mitigate their disruption operations.

The MDO concept proposes deploying in smaller packages to dispersed seaports and airports of debarkation. Field Manual 3-0, Operations, states that the side that most rapidly builds combat power can seize the initiative. These deploying forces will be required to conduct joint reception, staging, onward movement, and integration (JRSOI) operations, including receipt of their allocated PWRM, APS, and munitions within the kinetic capability of enemy long-range fires. Significant strategic planning is required to balance the costs of staging large, consolidated material stockpiles against the associated risk incurred from A2AD strikes on those stockpiles while still making them operationally relevant. This article proposes a risk mitigation strategy for regional and global threats while reclaiming the fiscal benefits of economies of scale and identifying opportunities for additional efficiencies.

What is PWRM?

As defined in Chairman of the Joint Chiefs of Staff Instruction 4310.01E, Logistics Planning Guidance For Prepositioned War Reserve Materiel, PWRM refers to war reserve materiel strategically located to facilitate a timely response in support of combatant commander (CCDR) requirements during the initial phases of an operation. Rapid power projection centers on our ability to provide strategic air and sealift capabilities expeditiously to meet established and emerging crises. To act as a deterrent in competition, prevent adversaries from attempting a fait accompli attack, mitigate the tyranny of distance, and reduce the burden on the strategic lift, geographic combatant commands (CCMD) determine PWRM requirements to fulfill their operational plans (OPLAN)s as consistent with national strategic direction. Service components establish, fund, manage, and maintain PWRM located in the CCMD area of responsibility (AOR). By prepositioning stocks afloat and ashore, we reduce U.S. Transportation Command requirements to provide dedicated lift to support the movement of forces, equipment, and materiel. The Secretary of Defense (SECDEF) has Title X responsibility to provide overarching strategic guidance concerning planning and resourcing priorities. These link the DOD current and future needs for prepositioned stocks—such as desired responsiveness—to evolving national defense objectives and ensure financial resourcing is provided to maintain the PWRM. Evolving threats from global and regional adversaries necessitate the strategic locating of stocks along with a PWRM triad: expediting force closure through positioning in line with OPLANs, reducing the cost to store and maintain, and mitigating risk to stocks.

Bridging The Efficiencies Gap

Services and service components store PWRM and munitions across the globe in consolidated, service-specific warehousing and storage areas to gain the financial benefits of economies of scale. These operations generally have a single warehousing requirement, which includes the costs of facilities maintenance, climate control, energy, security, and other associated costs. They also have the benefit of a single, broadly written, large-scale statement of work to generate a single contract to operate the facility, manage and care for personnel, maintain and account for the materiel, conduct daily operations, and support operational requirements. However, given the current global environment, optimizing any one leg of the triad increases the risk to OPLANs that should be mitigated with deliberate decisions by the SECDEF, CCDR, component commanders, and the services. Allowing any one service to consolidate nearly all their PWRM or munitions in one storage location is an exceptionally grave risk—doing so could eliminate that component’s contributions to the OPLAN should enemy long-range fires target that location. Put simply, it is equivalent to putting all your eggs in one basket.

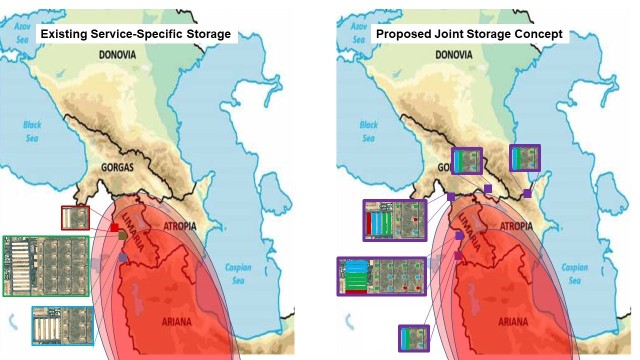

Seeking harmony—not balance—within the PWRM triad is key when determining how, where, and why PWRM is stored globally. Perfect balance is not always the answer, as commanders assume unequal risk or responsibility along all triad axes. Decisions are often made based on service-specific Title X requirements without seeing the benefits of joint solutions to common problems shared by all the services. If, however, service components coordinated joint force PWRM and munition storage requirements, the triad could be harmonized and smaller capability-sets executed across dispersed joint operating facilities closer to their intended point of use, including key OPLAN JRSOI nodes. Doing so would enable components and the services to gain back funding and contracting economies of scale by sharing oversight responsibilities and streamlining site operations costs proportionately to the requirements of each stakeholder. The graphic below depicts an exercise map illustrating current storage methods and proposes the alternate joint storage concept.

How Do We Fund Joint Operations?

Each location’s lead service is charged with the Title X responsibilities to develop, execute, and supervise contracted capabilities for joint support locations. There are at least three methods to fund and conduct joint storage operations in a manner that buys back the economy of scale enjoyed with large-scale, single-service storage operations. The first, and most easily controlled at the service component level, is a jointly funded contract. In this case, the lead service—typically the service with the preponderance of forces and requirements—would issue the contract, but all the components would identify requirements and fund their proportional share of the contract. If properly executed, this could afford maximum flexibility to support each service component’s unique requirements in a joint environment. The contract could be built to streamline contract line items, corresponding lines of accounting, and contract management functions unique to each service components’ requirements. This method requires extensive planning, execution, and management commitment from the joint community, but the result could ultimately achieve cost savings in a resource-constrained environment and improve the overall capability to urgently respond in times of crisis.

The second method is a lead service contract to conduct the joint storage operation, where the lead service is reimbursed through an Inter-Service Support Agreement. This case still retains the economy of scale and accomplishes readiness and dispersion objectives, but the financial benefits are realized at the service and DOD levels.

The third method is an inter-component memorandum of agreement. The two component commands agree on reimbursement through military interdepartmental purchase requests or other payment-in-kind arrangements. This method cannot be neglected because some munitions storage functions are still conducted by military personnel. In this case, one component may offer to conduct ammunition storage operations and ask another service to provide movement control functions, for example, an equitable force requirement that is also jointly beneficial.

One may argue that reconsolidating equipment and munitions at a joint support facility increase the consolidation risk that the concept is trying to avoid. However, the joint force realizes reduced overall adversarial risk by dispersing service-specific capabilities across multiple joint nodes with smaller footprints. Dispersing service capabilities across joint storage locations reduces threats to large stockpiles, operationally links capabilities to points of intended use, and optimizes costs through shared facilities with common-user requirements.

Cross-Combatant Command PWRM Planning Adds Efficiencies

The U.S. military can further improve our ability to influence competitor decision calculus, enable rapid deployment, and more safely penetrate enemy A2AD or long-range fires capabilities by developing joint PWRM and munitions storage activities near the seams of CCMD boundaries. Our adversaries are not hindered by self-imposed geographic boundaries and thus see the globe as one strategic battlefield. Blurring our geographic boundaries through global reach and expeditious response increases deterrence. It provides more opportunities to exercise equipment sets and the tools to simultaneously influence multiple AORs through snap deployments and exercises. Efficiencies are created when critical stocks are prepositioned such that the PWRM triad becomes mutually beneficial to one or more CCMD due to geographic proximity along key ground or sea lines of communication. CCMDs would have access to these stockpiles and could use them for exercises and planning for contingency operations serving multiple OPLANs. Posturing along CCMD seams could serve to assure multiple partners, deter multiple adversaries, and potentially reduce the overall requirement for forward-positioned stocks.

Conclusion

Proper positioning, planning, and resourcing of PWRM and munitions remain vital to maximize assurance to U.S. allies and partners, deter adversarial aggression, and readiness for crisis response or OPLAN execution. While the threat of long-range fires changes the U.S. posture calculus for positioning PWRM and munitions, dispersing and protecting forward resources through joint solutions can create dilemmas during competition, reduce force closure times in crisis, and create potential cost savings. Further policy changes to create cross-CCMD resourcing can increase readiness and reduce global storage requirements while simultaneously reducing force closure timelines and risk to force and mission during LSCO.

--------------------

Col. Ronnie Anderson is currently serving as the division chief for U.S. Central Command J-4 plans and operations divisions. He holds a master’s degree in Logistics from the Florida Institute of Technology and a master’s degree in Strategic Studies from Marine Corps University.

Maj. Eric Baca is currently serving as a joint logistics planner and PWRM manager for U.S. Central Command J4 plans and operations divisions. He is a certified theater logistics and joint planner and holds a master’s degree in Supply Chain Management from Kansas University.

--------------------

This article was published in the Spring 2022 issue of Army Sustainment.

RELATED LINKS

The Current issue of Army Sustainment in pdf format

Current Army Sustainment Online Articles

Social Sharing