The production and transportation of goods and services to those who need them has evolved over the centuries. However, at its most basic, supply chain management (SCM) relies on converting data about the availability of materials and the associated demand for said supplies into plans of action to ensure the conveyance of the materials when and where the end-user needs them.

In June of 1812, Emperor Napoleon Bonaparte led his Grande Armée in an invasion of Russia. By the end of the year, he abandoned the campaign. In 1975, Steven Sasson, an engineer working for Eastman Kodak, invented the first digital camera. The company filed for bankruptcy in 2012. In both of these examples, improperly executed SCM led directly to failure.

Napoleon’s invasion of Russia is a classic case study in the failed planning and execution of SCM. After a summer and fall of campaigning through Russia, his army, starving and freezing, retreated during the harsh Russian winter because there was no supply chain capable of supporting them. The French planned a long-distance campaign focused on operational goals without considering the inherent challenges of establishing supply chains over vast geographical distances.

The lesser-known story of Eastman Kodak’s demise communicates a cautionary tale at the opposite end of the supply chain spectrum. Eastman Kodak placed too much emphasis on supply chain optimization and not enough on operational needs. In the 1970s, Kodak was a behemoth of a company that owned every part of the print photography industry. Their supply chains enabled vertical integration that allowed them to profit in every aspect of the photography industry: the cameras, the film, the chemicals that developed the film, the photo paper, the printing kiosks, etc. Despite pioneering digital photography in 1975, Kodak was reluctant to alter their historically strong supply chains to adopt digital photography. As a result, Kodak incrementally ceded market share until the company’s products became obsolete as print photography gave way to digital. The failures of Napoleon and Kodak highlight the importance of having leaders knowledgeable of supply chains and capable of managing them.

Supply Chain Balance

Efficiency and effectiveness are often at odds with each other in SCM. Simply put, efficiency targets reduced costs, and effectiveness targets high availability rates. It is important to strike a balance best suited toward the goals of the organization that the supply chain supports. As in the Eastman Kodak example, an organization can fail if it focuses too heavily on efficiency. An overreliance on effectiveness can lead to failure resulting from unmanageable costs or an assumption that supply chains will be effective under all circumstances, such as Napoleon’s Grande Armée. It is important for the Army to develop leaders with an awareness and understanding of its supply chain needs. The Army tends to prioritize effectiveness over efficiency. This is both important and correct. While the Army has an obligation to be good stewards of taxpayer dollars, Army sustainers also need to ensure warfighters have the supplies they need at the right time and place to complete any mission. However, this does not mean we should not search for improved efficiency. Increased efficiency and effectiveness are mutually exclusive in an already optimized supply chain. Only then is it impossible to improve efficiency or effectiveness without sacrificing the other.

Army Logistics University (ALU) offers a Defense Supply Chain Management course that examines the effective and efficient balance and mechanics of the Army’s supply chain. The course provides enterprise-to-tactical defense SCM instruction to qualified military and civilian personnel assigned to operational DOD supply chain positions. Students learn how to analyze the management and operations of the defense supply while studying its competencies and major functions. The primary audience for this course is Army Civilians assigned, or on orders to, a management assignment requiring knowledge of defense supply chains and distribution management. Exposing students to a broad view of the Army’s supply chain enables them to make decisions that are in line with optimizing the Army’s overall supply chain rather than sub-optimizing within a silo of excellence. The SCM course is a key component of the educational opportunities provided by ALU to broaden career development and enhance the performance and skills of mid-level managers working within the DOD supply chain environment.

Supply Chain Visibility

Visibility and understanding of supply chains are vitally important to sound decision-making. Without a clear comprehension of what is happening within the supply chain, leaders can’t make informed decisions. This idea is so important that Army Doctrine Publication 6-0, Mission Command: Command and Control of Army Forces, specifies creating a shared understanding of the operational environment as one of the seven principles of mission command. Possessing a shared understanding of Army supply chains is equally important. Organizations develop programs and implement procedures to maximize this understanding to enable and enhance supply chain visibility. For example, as part of the military response to COVID-19, the Countermeasures Acceleration Group (CAG) developed a comprehensive tracking and analytics system to maintain visibility of all activity involving the CAG mission. The CAG system provides real-time tracking visibility and data analytics of all aspects of their operation, including CAG planning, vaccine and therapeutics development, supply chain management, distribution, real-time tracking and analytics, vaccine control, security, and assurance to every stakeholder.

In 2016, Airbus launched its Digital Control Room. Like the CAG system, this Digital Control Room provides Airbus with visibility throughout their entire supply chain. Total supply chain visibility enabled CAG to identify vaccine manufacturers experiencing potential issues and respond with subject matter experts for assistance and problem resolution. The Digital Control Room does the same thing with parts manufacturers for Airbus. Having these systems in place enables organizations to maintain a holistic view of their supply chains and identify/address bottlenecks before they become an issue.

Civil-Military Supply Chain Links

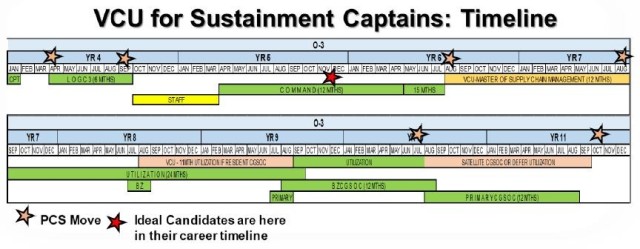

Many supply chain principles carry over from the civilian sector to the military. Due to the military’s reliance on the industrial base, there is an inherent link between military and civilian supply chains. Therefore, incorporating supply chain principles developed in the civilian sector into the military is important when developing synergy and efficiencies. To accomplish this, the Combined Arms Support Command (CASCOM) maintains a collaborative academic relationship with the Virginia Commonwealth University (VCU).

Every year, CASCOM sends Army captains to VCU to complete a master’s degree in Supply Chain Management, a program centered on global supply chain management, innovation, and analytics. For the conclusion of this program, VCU professors guide the students through a capstone project centered on a real-world problem that an Army organization is facing. Upon graduation, the officers serve in a utilization assignment where their organizations directly benefit from the institutional knowledge gained at VCU. The VCU master’s program ensures that the Army has a steady supply of leaders on the edge of emerging SCM techniques and practices, vital for a military operating in an environment facing constant supply chain challenges.

Data Analysis in SCM

Data production and gathering are more prevalent in an increasingly digital world than ever. Supply chains produce massive amounts of data in every aspect of their operations. However, data is useless without the ability to process and analyze it. This holds true in the Army and the civilian sector and is why ALU is developing new strategies to teach Army logisticians how to analyze data. In fiscal year 2020, ALU began offering the Data Analysis and Visualization (DAV) course. The DAV course is intended for civilian and military students who collect or analyze data regularly or personnel who use data to communicate to others. The course aligns with the Army G-4’s desire to build analytic talent and create a smart data culture. Graduates of the DAV course can garner information from data using descriptive and predictive statistics and present findings using visualization techniques. Having knowledge of these tools arms graduates of DAV with the skills they need to see what is happening in their supply chain and present recommendations to their leadership.

Supply Chain Risks

New and emerging threats to military operations also threaten military supply chains. For example, cyber-attacks can shut down a supply chain just as quickly as they degrade operational security. The ransomware attack on the Colonial Pipeline in May 2021 is a recent reminder of this. The attack shut down the largest pipeline system supplying fuel to the Southeast United States for nearly a week. The COVID-19 pandemic has also revealed a plethora of potential areas of supply chain vulnerability. Labor issues, transportation shortages, and the non-availability of sole-source supplies because of lockdowns are just a few examples. There also are unpredictable supply chain disruptions, such as the container ship Ever Given running aground in the Suez Canal in March of 2021, resulting in the complete closure of the canal for a week, effectively cutting the supply chain from and to a large portion of the world.

The military is not immune to these potential disruptors. Supply chain risk management is a key concern for the U.S. military. The Defense Logistics Agency, Joint Munitions Command, and Army Futures Command all have deliberate processes in place to analyze their supply chains and detect potential risks within them. Military organizations increasingly use many of the same innovative techniques as civilian companies, such as machine learning, to manage their supply chains.

Conclusion

It is vital that the Army continue training leaders to understand its supply chains and stay abreast of current SCM techniques. Doing so can help avoid crucial SCM errors such as the ones that led to the demise of Napoleon Bonaparte’s Grande Armée and the Eastman Kodak Company. Proper supply chain management enables the Army to maintain agile and secure supply chains that are always ready to support the next mission.

--------------------

Capt. Matthew G. MacDonald currently serves as the course director for the Supply Chain Management course at the Army Logistics University. He holds a Bachelor of Arts in Economics from Binghamton University, New York, and a Master’s in Supply Chain Management from the Virginia Commonwealth University.

Dr. Robert Neeley currently serves as the chairman of the Enterprise Management Committee in the College of Applied Logistics and Operational Sciences at the Army Logistics University. He holds a Bachelor of Arts in History from the University of North Carolina at Charlotte, a Master of Art in Organizational Management from the University of Phoenix, Arizona, a Master of Arts in National Security and Strategic Studies from the U.S. Naval War College, and a Doctorate of Business Administration from Walden University, Minnesota.

--------------------

This article was published in the Spring 2022 issue of Army Sustainment.

RELATED LINKS

The Current issue of Army Sustainment in pdf format

Current Army Sustainment Online Articles

Social Sharing