Since operations began in September 2012, the Fort Benning Water Resource Facility has provided clean, safe drinking water to the Benning population by employing tiny technology to produce huge capability and capacity.

“One of the things that makes our plant unique is that we are a membrane filtration plant, one of four in the state of Georgia,” explains Vic Burchfield, Senior Vice President, Columbus Water Works.

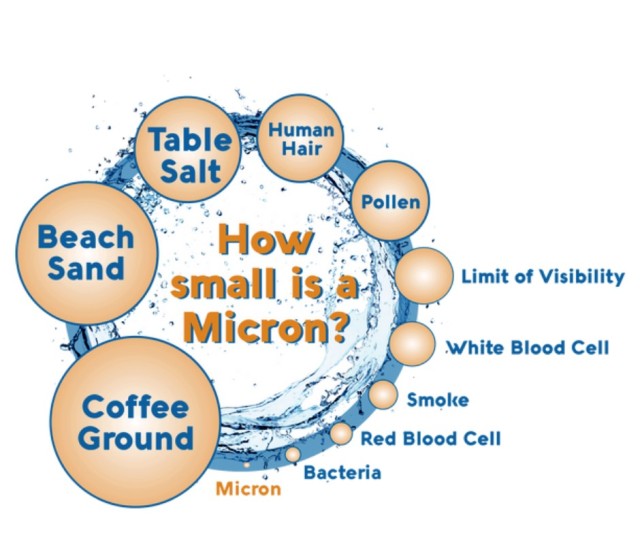

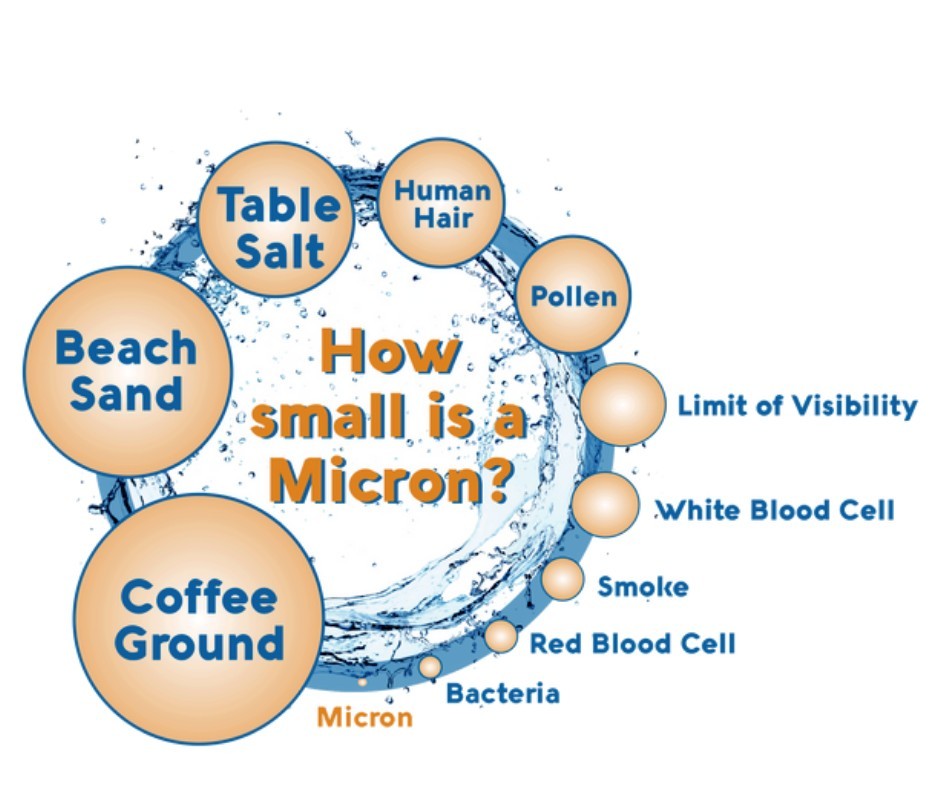

What’s a micron?

Inside the membrane filtration assemblies, water passes through .03 micron-sized pores in the walls of a “fiber” tube, leaving trapped contaminants behind and purifying the water. A micron is one-millionth of a meter.

“Filtering at that level makes it easy for us to exceed our partnership goals for clean water,” said Louis Smith, CWW Assistant Superintendent.

To help put the filters’ capability into perspective, the smallest things visible to the naked eye are about 40-50 microns in size and the human hair is about 70 microns across. In short .03 micron is very small, smaller even than small bacteria which are about 5 microns.

“One of the additional advantages of membrane filtration is, because it is a cleaner filtering system, we use less chemicals after filtering than a conventional plant,” added Burchfield.

Choice not chance

Water quality testing is an ongoing mission for CWW, it happens hourly within the treatment plant and daily across Fort Benning at various sampling stations approved by the Georgia Environmental Protection Division, the state’s version of the federal Environmental Protection Agency.

“We have over 110K tests we do every year, not only through our operators at the plants themselves, but from our consolidated laboratory, located in Columbus, where we test the whole system,” said Burchfield.

Water flowing through the Fort Benning system goes from intake to distribution in about eight hours. It was designed and built to meet the demands of the installation now and in the future.

“Constant monitoring and hourly testing allows us to detect any possible issues quickly and the time to adjust before a problem can form,” added Smith.

The plant’s treatment-on-demand model of operation, coupled with testing, provides the plant quick reaction and recovery capabilities if any issue was to ever arise.

The water must flow

Redundancy and reliability are key components in the plants design and reflective of the close partnership between Fort Benning and CWW. The military need for readiness can been seen in the machinery, systems, and practices in place to keep clean water flowing regardless of external forces.

One of the three intake pumps can feed the membrane filtration assemblies and one of the three generators can power key systems in the event of a power outage. The old treatment plant drew from Upatoi Creek, water now comes from Chattahoochee River, increasing flow available to the plant.

“We can control the entire operation from this one computer system,” explained Smith. “Every plant, every pump, every tank, you can see everything from right here.”

The computer system has redundancy too, from its sister systems at the Columbus treatment plant.

“We have interconnects from Columbus that flow into the Fort Benning distribution system,” said Burchfield. “The operators there can see up there, what’s going on down here, the same way we can see up there.”

The plant is capable and permitted to clean 12 million gallons of water a day and usually produces between two and three. This additional output capability, and interconnections with the Columbus distribution network, combine to create an overall system with enough redundancy to be highly resilient and reliable over time.

Cybersecurity

Security is key to reliability, both physically and virtually. Key resources and infrastructure, such as water and power, are vital to every day Americans and the stability and security of the nation.

“All water utilities our size have to do a cyber-assessment along with a vulnerability assessment, the results of which are included in our emergency response plan,” said Burchfield. “Cyber is now a key component, of contingency planning, along with natural hazards and terrorism.”

Various organizations exist, such as power and water Information Sharing and Analysis Centers, to facilitate better protection against threats.

“We are part of the WaterISAC, this is a group that concentrates just on the water, issues from terrorism to cybersecurity to anything that would be harmful to a water system,” said Burchfield. “We are alerted to any issues that may require action.”

Dedication

The plant’s pedigree is borne out in the sheer numbers and level of awards and accolades it has been awarded and in its commitment to the water treatment community at large. CWW Fort Benning is a member of multiple professional organizations such as the Georgia Association of Water Professionals and an active participant in improving water quality practices and policies.

"We simply want to strive for excellence just like all of Fort Benning," Burchfield said. "Fort Benning's value of excellence is the same that we share at the Water Works. We want to provide great service to the residents of Fort Benning and provide a high quality drinking water."

Social Sharing