FORT CAMPBELL, Ky. – The 101st Airborne Division (Air Assault) is at the forefront of innovation across the Army, and its new EagleWerx Applied Tactical Innovation Center is providing Soldiers with the resources they need to push their ideas even further.

EagleWerx has provided backing to approximately 10 ongoing projects since launching in November 2020, leveraging bottom-up innovation to increase mission readiness.

Major Benjie Hall’s concept for an automated arms room system is an EagleWerx-backed idea that will be showcased in the next round of Dragon’s Lair, the XVIII Airborne Corps’ innovation challenge. The competition is structured similar to “Shark Tank” during which Soldiers present their projects to a panel of experts and commanders.

“If you get leader buy-in at that level, if they’re putting their name and position behind developing something, you’re going to get a lot of input early on,” said Hall, chief innovation officer and division force management officer, 101st. Abn. Div.

EagleWerx capabilities further increased when a physical location opened at 89 Screaming Eagle Blvd. in August.

“This is the first time we’re giving Soldiers the hard physical resources to work on things,” said Capt. Lauren Hansen, deputy innovation officer, 101st Abn. Div. “Before we were just helping them get expertise from the outside, advocating for them and helping with design sessions, but for Soldiers to be empowered they need to have resources. Having a division-level program gives them that overhead, and the resources we have are pretty wide.”

Offerings at EagleWerx include 3D printers, laser cutters, robotics kits, sewing machines, toolsets, electronic design stations, collaborative workspace and more – with plans to bring in additional resources including workshops, classes and leader professional development programs.

“We approach projects on a case-by-case basis because innovative solutions aren’t just tech,” Hansen said. “They could be processes, software or something really small and simple. And when Soldiers come together and do these exercises, they get really excited because they all feel heard, and they have the opportunity to be creative. We get the social truth instead of the loudest voice in the room, and that’s something Soldiers really gravitate toward.”

Hansen said the current operations at EagleWerx are part of a soft opening, with tentative plans to host a ribbon cutting and grand opening in December. The facility will eventually have three full-time employees and competitive quarterly fellowships for junior non-commissioned officers.

“They’ll come in on a rotation for 90 days and they’ll learn how to use design methodology to find creative solutions,” she said. “Then they get to work here full-time, and when they go back into the force, they can spread what they learned. That means they keep their operational relevance, but they also get the time to work on projects that are really meaningful to them.”

Having full-time employees at EagleWerx is key in helping Soldiers like Chief Warrant Officer 2 Ron Rivera, Unmanned Aircraft Systems operations officer, 2nd Brigade Combat Team, 101st Abn. Div., realize their passion projects.

Rivera has been workshopping new propeller designs for the RQ-11B Raven since he served with 5th Special Forces Group (Airborne) in 2016 and partnered with EagleWerx in July with the goal of refining and implementing an Armywide solution.

“Now that I’m the UAS operations officer, one of my primary goals for the brigade is to ensure our Raven program stays healthy,” he said. “There are commercial UASs coming off the shelf that are a lot more suited to handling some of the things we do on a day-to-day basis, specifically when it comes to the Raven’s noise signature. It can get pretty loud when you ramp up the noise signature or the throttle settings, and the batteries that are issued with the system are getting old at this point so they’re running low on capacity.”

EagleWerx is currently 3D printing various designs for the propeller system, which Rivera said should be a marked improvement once they refine it.

“It’ll drastically increase the flight time and reduce the noise signature of the Ravens, so you’ll have stealthier operations and the ability to infill closer to an objective,” he said. “We’ll print out a couple, probably do a test run and get some statistical data over the course of 20-30 flight hours to show how much we were able to reduce the battery usage in a certain amount of time versus the traditional propeller the system was designed to use.”

After achieving those results, Rivera said the goal is to pitch the design to higher headquarters and the Project Management Office, UAS so it can be implemented Armywide.

“If we design something, test it and it’s successful, we can then give that to the U.S. Army Research Lab, U.S. Army Combat Capabilities Development Command or U.S. Army Futures Command and say it saves us tens of thousands of dollars by reducing energy costs,” Hansen said. “For example, the propeller: let’s say it cuts the battery time by a quarter. If you mass produce that and implement it across the Army, you’ve probably saved hundreds of thousands of dollars.”

Hall hopes his automated arms room system concept will eventually be implemented Armywide and said it could reduce equipment check-out times by at least half.

“Right now, Soldiers have to stand in line and hand-sign two different documents just to get authorized to take out equipment for accountability purposes,” he said. “They do the same thing in reverse when they come back in, so even though it sounds like a short process a Soldier’s spending a minute at a time doing that. When you take an entire company of Soldiers, that’s a lot of time spent drawing out weapons. My concept is that we automate that process so the Soldiers can come in and use their ID card instead of hand-signing.”

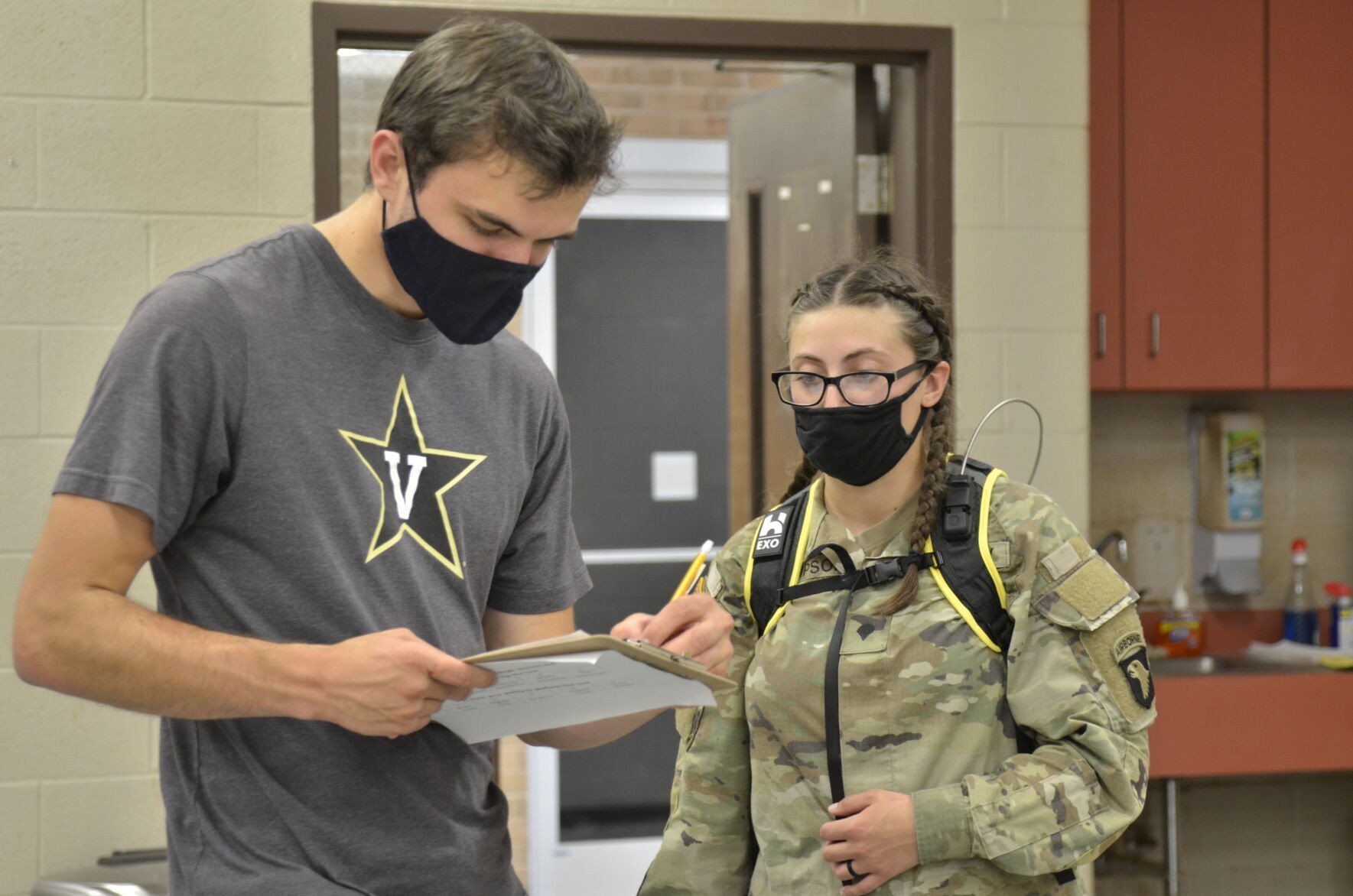

That means building a database with a strong user interface, and Hall is currently gathering feedback from Soldiers through EagleWerx to make sure it addresses their needs. Although the project is in its early stages, he is confident the concept has what it takes to bring in key backers at Dragon’s Lair.

“It’s easy to implement and it’s not something that requires potentially extensive periods of research and development,” he said. “I believe within the next six months we could be impacting Soldiers across the installation as far as the time spent checking weapons in and out, and how much time is spent away from training doing what tends to be a mundane task.”

EagleWerx strives to develop most concepts into mature, minimum viable projects within six months, and community partners like Vanderbilt University and Middle Tennessee State University are helping them do just that.

“So far we have two projects that we’re currently working on with Vanderbilt,” Hansen said. “For one of them, they developed an exosuit based on engagements with Soldiers out in the field from 3rd Brigade, especially those who are in fires, because they do a lot of heavy lifting and they do it all manually. It’s designed to reduce the physical burden by 50-70 pounds.”

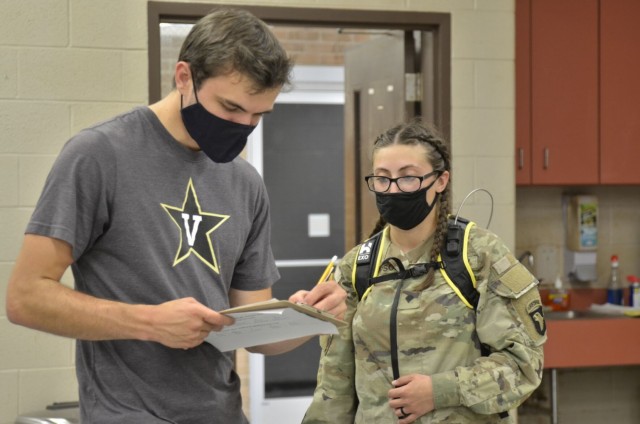

Researchers from Vanderbilt are designing the suit based on continuous feedback from Soldiers, with one of the most recent tests hosted Aug. 25 at the EagleWerx Applied Tactical Innovation Center.

“We’re really focused on building a soft, passive, lightweight exosuit that can be integrated into Soldiers’ uniforms,” said Shimra Fine, an exosuit technician at Vanderbilt. “The goal is to reduce and prevent injuries to the lower back, because that’s a leading cause of why Soldiers are out of work.”

Soldiers from 3rd Brigade Combat Team completed a variety of exercises to measure their strength and mobility using the exosuits, then spoke with researchers and completed surveys about the experience.

“It’s great to be able to get direct feedback from the user, because that’s the whole fundamental idea behind this project,” Fine said. “There have been issues with exosuit projects in the past when the Army’s tried to adopt them, and I think a lot of that was due to a lack of Soldier involvement early on.”

EagleWerx as a whole is geared toward allowing Soldiers to play a major role in new project developments, which Rivera said is incredibly empowering.

“I think it will increase motivation and drive for Soldiers to come up with new ideas, and to have a safe space to pitch them,” he said. “That’s not to say people are telling them their ideas aren’t good, but a lot of time they’ll hear that we don’t have time because we need to meet mission. If you have an organization like this that’s well-resourced and well-funded, then you have the ability to brainstorm those ideas and allow them to culminate in something useful. I think that’s going to catch on like wildfire, and this place will stay very busy.”

Social Sharing