ROCK ISLAND ARSENAL, Illinois – Clothing, equipping, transporting and feeding approximately 25,000 Soldiers as they navigate through the Training Doctrine Command’s (TRADOC) Maneuver Support Center of Excellence (MSCoE)’s three schools, located at Fort Leonard Wood, Missouri, is a major effort the base’s Logistics Readiness Center (LRC) helps support.

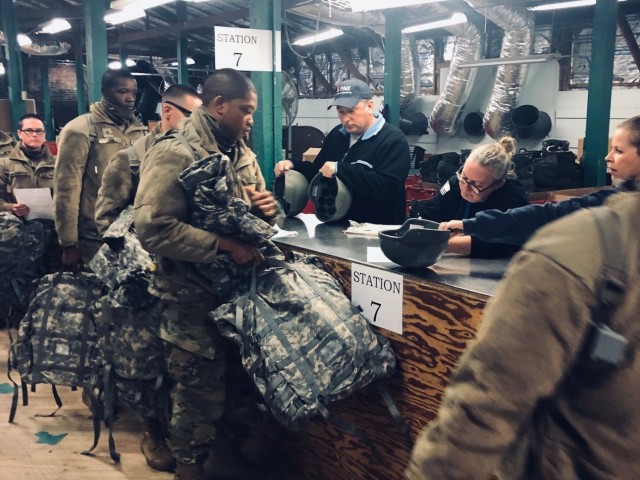

A team at Army Contracting Command-Rock Island (ACC-RI) provides the acquisition support that keeps the LRC running smoothly under the Enhanced Army Global Logistic Enterprise (EAGLE) Fort Leonard Wood contract. From the get-go, Soldiers come into contact with the LRC’s services, via the two phases of the Clothing Initial Issue Point, in which they receive their uniforms in the first phase and Army Service Uniform in the second phase.

In addition to clothing Soldiers, EAGLE contractors also support the transportation of all joint service trainees and international students – approximately 10,000 personnel are moved via bus across the installation daily.

According to the LRC’s Plans and Operations Center, EAGLE contractors also support maintenance efforts of the equipment necessary to enable training by having the sole maintenance support mission for all Commercial-Off-The-Shelf equipment for the schools. This consists of approximately 2,500 pieces of equipment ranging from simple lawn equipment to more complex equipment such as industrial tractors and marine equipment. Additionally, they support all of the equipment in the installation’s 13 Dining Facilities, serving approximately 1 million meals a month – one of the largest in the Department of Defense (DoD).

The contract was awarded in May 2018 and has an estimated value of $30 million. To date, two of the four option years have been exercised.

EAGLE as a training vehicle

In early 2020, post-award administration was assigned to contract specialists Shawn Kerr and Ryan Oliver, who are in the center’s Intern Homeroom (IHR), under Nathan Bowers, a contracting officer and IHR trainer. In March 2021, Bowers and Oliver were reassigned to other center requirements and Ryan Pierce, contracting officer, as well as contract specialist Rose Meyrer and intern contract specialist Sophia Muckenfuss, were assigned to the contract.

Bowers said this contract gives the new hire interns great experience in supporting an enduring mission. The center’s IHR recently adopted a structure in which interns are not only exposed to quick, churn and burn contracting actions, rather, they are assigned to a program-level contract for a comprehensive education in the various types of contracts assigned to ACC-RI.

“With this contract, they get to experience the daily ins and outs of post-award contract administration,” said Bowers. “They get to interface with the contractor and customer on a monthly, if not bi-weekly basis, so we are teaching them how to have open communication with the contractor, the customer and to be that go-between to keep the lines of communication open and ensure mission success and readiness for the Soldiers there who are going through their basic training.”

Oliver said working on the day-to-day actions has been valuable to his education.

“We’re getting to see the funding modifications, the obligations, the Undefinitized Contracting Actions, and all the other little pieces, but it’s all tied to the same contract, so we get to retain the knowledge over the course of the actions,” said Oliver.

Further, Kerr said working on this contract has given him the valuable opportunity to work with the main contracting writing system the center uses.

The team also recently issued a modification to increase the within-scope requirements to add the installation’s Navy and Marine Corps customers’ maintenance missions. This proved to be a challenging task because the contracting support they were receiving from another organization ended quickly, necessitating an urgent response by ACC-RI.

“We took what was an urgent requirement and put it on this EAGLE contract and based on the efforts of our contractor to increase their manning level to go out and recruit and hire the people who were on the previous contract, they on-boarded a new group of workers for a Jan. 1 start date, and the work never stopped,” said Bowers.

In the process, the intern team was able to get a first-hand look at the flexibility EAGLE contracts were designed to provide.

“These five-year requirements are built to ebb and flow with changing requirements, whether we need to add new customers or address adjustments to changes to the workload requirements,” said Bowers.

EAGLE’s flexibility also helped the team address the customers’ COVID response, including the need to facilitate social distancing and quarantining.

“Providing required separation between the Soldiers meant expanded bus routes with additional routes and drivers,” said Bowers. “The LRC, the Contracting Officer Representative, Carrie Peterson, along with the contractor’s management facilitated a COVID plan that had no instances of mission failure.”

EAGLE Fort Leonard Wood not only serves as a shining example of meeting the Army’s readiness priority, Bowers said, it also shows cohesion between the DoD and industry as well as a way to ensure the center’s newest employees are well trained.

“The mission at Fort Leonard Wood is really a microcosm of what we are trying to do in the homeroom and within the EAGLE contracts themselves,” said Bowers.

Social Sharing