The Department of the Army G-4 brought together three experts for a conversation about how their respective strategic Army logistics commands are foundational to the joint fight. The panel included Maj. Gen. K. Todd Royar, U.S. Army Aviation and Missile Command; Maj. Gen. Heidi Hoyle, U.S. Army Military Surface Deployment and Distribution Command (SDDC); and Col. Gavin Gardner, Joint Munitions Command and Joint Munitions and Lethality Life Cycle Management Command.

Q: How do you see Army logistics' strategic role in the joint force evolving as we transition to fighting in a contested, multi-domain environment?

Royar: In terms of doctrine and process, I think we are pretty well set. The role of Army logistics is sound, but the methods we use will continue to evolve. So, let me ask the question a different way: How do we provide the joint warfighter the same high level of logistics support, but do so with greater efficiency and effectiveness?

I believe the answer is we reduce the overall sustainment requirement, which we can achieve in several ways. For example, we can consider sustainment solutions at the front-end, during weapon system development. If we design a system that doesn’t consume parts as quickly and increases the reliability on the battlefield, we will carry fewer parts, ship fewer parts, and contract for fewer parts.

Another mechanism for reducing the sustainment requirement is advanced manufacturing. Imagine having the ability to manufacture a part on the battlefield—as opposed to bringing the weapon system all the way back to the strategic support area for repair. It is a massively complex endeavor, but advanced manufacturing would greatly reduce our sustainment footprint overall.

Gardner: Maj. Gen. Royar brings up a good point. How do we modernize to support the systems that will come online to enable the multi-domain operations (MDO) ready force? I think we do it by prioritizing resources, both the physical infrastructure and the people. Keeping in line with the Chief of Staff’s People First strategy, we need to consider how we transform and develop an organic workforce that is capable of sustaining today's requirements but during large-scale combat operations (LSCO), from an initial surge to sustaining power generation in the long-term.

Hoyle: There are approximately 5,100 surface warriors around the globe, 2,600 of those are part of the Deployment Support Command (DSC), our reserve component partners, so we always keep the DSC at the top of our mind as we move through the planning process ensuring they can mobilize in a timely manner.

Our DSC recently realigned some of our units closer to our seaports. That realignment will enable a faster mobilization. It will also help with recruitment. After all, the skills our workforce needs for seaport operations doesn't necessarily exist in the interior of our country. By moving the DSC partners closer to our coastal operations, we have the right workforce with the right skills.

Another element of Surface Deployment and Distribution Command’s (SDDC) success as a small organization is our ability to utilize our “fourth component”. While Army components one, two, and three are the traditional Active, National Guard, and Reserve Soldiers, our fourth component – our commercial carriers and partners, exponentially increase our distribution capability and they are our inextricable link making it possible for us to accomplish our mission.

For example, within the Trucks and Highways Program, we tap into more than 700 commercial carriers, which give us access to more than 1 million trucks. SDDC conducts operations at 23 continental United States seaports as part of the Strategic Seaport Program and an additional 180 seaports around the globe. This allows us to move from the continental United States through the strategic support area and project forces closer to the fight. Our brigades regularly exercise these seaports to keep them open and vibrant, delivering our combatant commanders options during planning and flexibility during operations.

Gardner: DOD has directed us to look holistically at the supply chain to minimize risk by identifying, monitoring, detecting, and mitigating threats. We need to know the points of failure and shore up any vulnerabilities. For example, we can outsource manufacturing to a friendlier country or even consider producing critical items domestically. Every supply chain decision should come with a risk assessment and, obviously, resources.

Hoyle: We also need to consider cyber as we evolve to meet the requirements of contested multi-domain operations. We have to strengthen our cybersecurity and make it more resilient. As SDDC develops multilateral contracts with our fourth component partners, we place requirements into the contracting obligations to increase their cybersecurity posture. Without doing so, we create an even greater risk during contested operations.

Q. What are your organization’s specific roles and contributions to Army support to other services?

Hoyle: From a holistic perspective, the SDDC provides support to other services and the joint force daily. I think of SDDC as the enabler—the connective tissue—for the joint operations of the U.S. Transportation Command (USTRANSCOM). The Air Mobility Command provides the airlift and the Military Sealift Command (MSC) conducts ocean vessel movements. We are the connective tissue for getting equipment to the port, conducting port operations, transitioning equipment to our sealift partners, and conducting port operations on the other end.

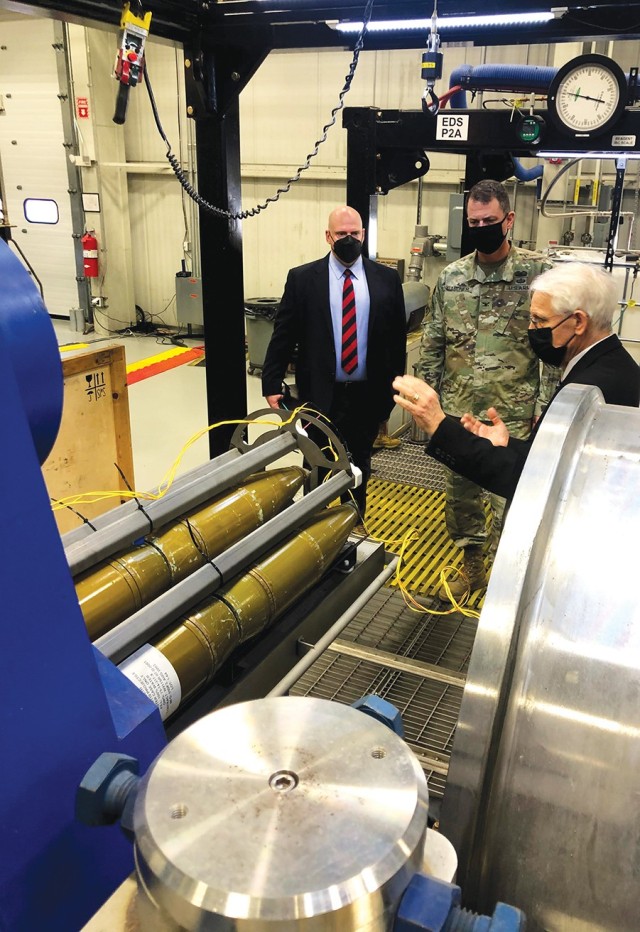

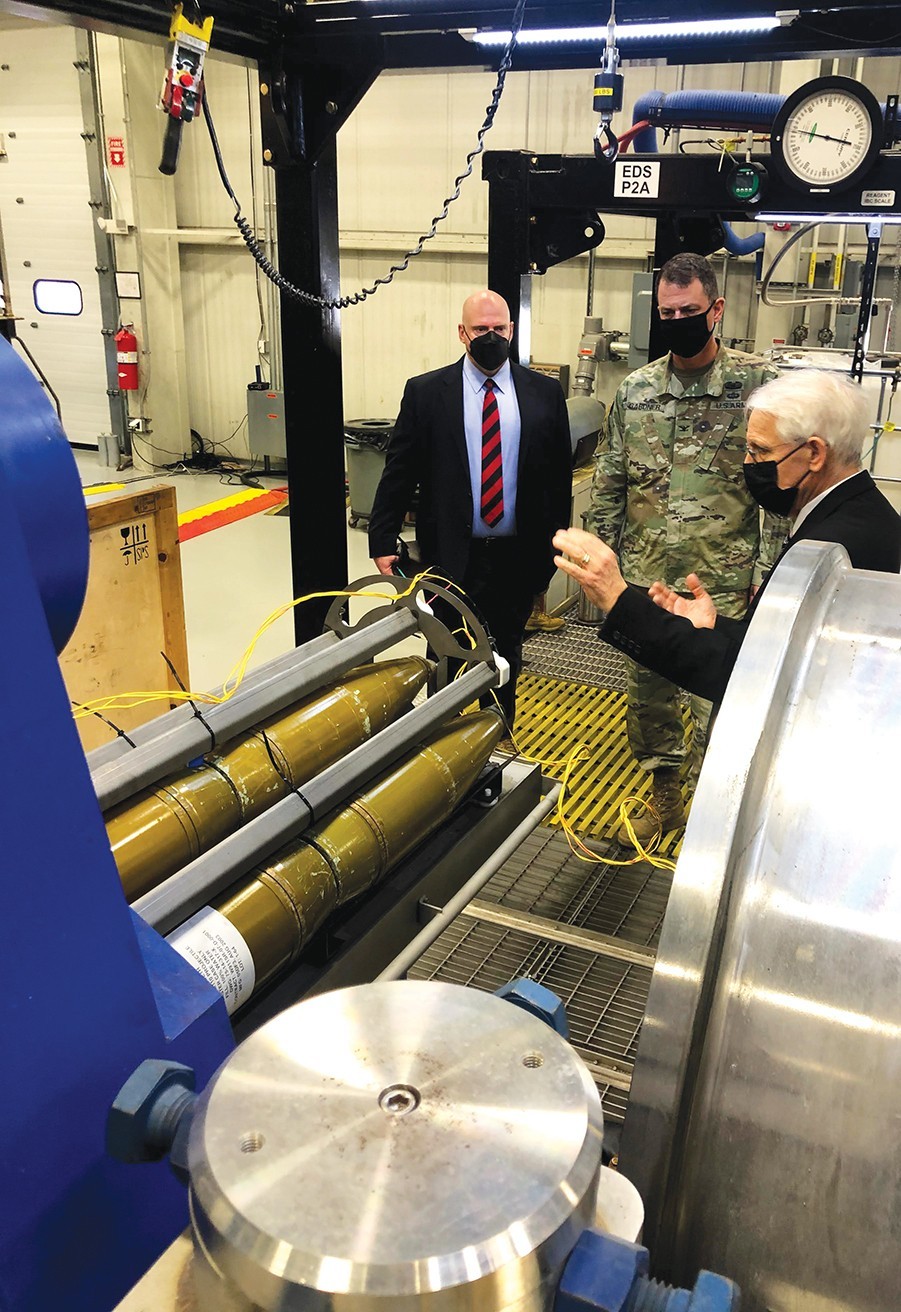

Gardner: The Joint Munitions Command (JMC) is also an inherently joint operation. Our core function is to produce, distribute, store, and demilitarize all the conventional munitions as well as ensure stockpile reliability. It is about making sure the ammunition is ready to go and will perform as designed. We perform these functions for all our military services, but we also perform them for other government agencies. This is important because LSCO in a multi-domain environment will require a whole-of-government effort.

Royar: As the name implies, the Aviation and Missile Command provides two major commodities to our joint partners. The first is the rotary wing aircraft. Corpus Christi Army Depot serves as the DOD’s center of excellence for rotary wing repair and overhaul. The Army and its sister services have very similar systems—they fly Blackhawks; we fly Blackhawks—so the extension of support is understandable. The second is the missile component. We provide for the repair, overhaul, recapitalization, and stockpile reliability testing of the family of missiles and missile systems operated by the Army and the other services.

We provide the same support to our foreign partners. When I think of our foreign partners, interoperability becomes key.

Q: How do you envision that mission set changing as we move toward LSCO in a multi-domain environment?

Royar: As we move to LSCO, the need for commonality becomes even more critical. If one of the services or foreign partners does something that is just slightly different or vice versa, the sustainment mission becomes much more difficult, especially from a supply perspective. Systems that are not interchangeable at the point of need put more stress on Maj. Gen. Hoyle's organization. Therefore, commonality will be critical and should be one of the major drivers for changing the way we support our warfighters.

Gardner: The joint force will be taking a closer look at dispersion as MDO and the Joint Warfighting Concept (JWC) develop. Today JMC distributes ammunition through our partnerships with SDDC and Air Mobility Command. We push very large volumes based on set schedules that meet the combatant commanders’ requirements. As we go into the future, we may have to reconsider how we distribute ammunition from the strategic support area to the end-user. Maybe more combat-configured shipments in smaller volumes. JMC is very attuned to the changes within the JWC, and we will adapt accordingly to meet the joint services’ requirements.

Hoyle: Because our daily mission is inherently joint, I don't foresee any significant changes as we move to LSCO. Except, as Maj. Gen. Royar mentioned earlier, maybe doing it more efficiently and effectively and certainly in a greater capacity.

Q: Support to other services is a huge piece of the Army logistics mission set. How do we better “think joint,” “plan joint,” and “sustain joint” as we look through the lens of setting the theater and power projection?

Hoyle: Air Mobility Command and SDDC are co-located on Scott AFB with USTRANSCOM, and everyday operations here are very joint in nature as we support the Joint Deployment and Distribution Enterprise, or JDDE.

Key to DOD’s success in joint thinking, planning, and sustaining is the Joint Planning and Execution System (JOPES)—DOD’s planning repository. With all joint requirements built into JOPES, we can conduct planning operations to provide the timeliest and most cost-effective solutions for the DOD.

Ammunition is a great example of how we serve and think jointly every day. We recently conducted an exercise where we moved ammunition for the Army, Air Force, Marines, and the Navy from JMC’s ammunition depots, plants, and arsenals to Military Ocean Terminal Sunny Point (MOTSU). MOTSU is one place where we are allowed to warehouse a significant amount of net explosive weight. In addition to the inherently joint nature of this mission, we also exercised contingencies with our industry partners, simulating a disruption of our standard rail solution and adjusting to a purely trucking solution. We were stress-testing the system. We wanted to see how we could use the facilities and test our operations to receive large quantities of containerized ammunition by truck only. Once the shipments were received at the ports, we put them on a military sealift vessel to move the ammunition overseas. That is just one example of how we are inextricably linked—JMC, SDDC, MSC, the larger joint force as well as industry.

Gardner: I agree. It requires routine interaction with our joint partners. My command works hand-in-hand with SDDC to develop the distribution plan that enables their concept of the operations, so the flow of munitions is sequenced with all the other commodities. It is the interoperability—of both planning and business systems—that is key to success.

Like the Army, our joint partners review their ammunition requirements annually. That information helps us define our mission. It also helps us drive the planning and execution of transportation and distribution.

In addition, as Maj. Gen. Hoyle highlighted from a JOPES perspective, transportation planning is evolving as the services’ enterprise business systems catch up. Even though munitions is an inherently joint function, and one of our Title 10 requirements, the military services are not fully integrated. As the Army evolves its business systems, we have asked for commonality—at least for munitions—so that we reduce the time between demand signal from our joint partners, the push of munitions at my level, and the pull of munitions by SDDC for movement to the point of need.

Every year we conduct joint munitions rehearsals of concept drills. We take a no-kidding go-to-war plan for a theater of operation, and we pull all munitions requirements for that plan. We then send the demand signal to SDDC for transportation planning. We also send on-the-ground physical demand signals to the industry (whether it is by truck or rail or even air) we exercise it all. As we exercise, we are in constant communication with our joint partners about both their current and future signals.

Royar: I absolutely agree with everything both Maj. Gen. Hoyle and Col. Gardner have said. But I think it is important—from a joint perspective—to get the requirements correct on the front end. Over time, we have done a better job working with our counterparts in our sister services. Together, we have determined the right capabilities for new weapon systems. But our services have different problem sets. For example, the control of corrosion is important to the Army, but it is more important to the Navy because they fly their helicopters off the back of a ship. It helps long-term if we can address those environmental and operational factors upfront.

To Col. Gardner’s point, Army Materiel Command has been working hard to give us a way to see ourselves from the enterprise business systems. The better we can see ourselves, the better our visibility, the greater our interoperability is across the board. If I know exactly where that one part is, I can get it to our sister service in the same combatant command when they need it.

Q. The Army of 2028 and 2035 will look radically different than that of today. What advice do you have for our young Soldiers who will join the ranks over the next decade?

Royar: My oldest son is joining the Reserve Officers’ Training Corps program this summer, and my advice to him is to make sure the foundation is solid. It is about Army values, ethics, and doing the right thing. If you have that foundation, you will have the ability to address the tactical challenges and be willing to innovate, change, and learn.

It is important to recognize that you can take risk—appropriate risk for your level. It is okay to try something. If it doesn't work, then let's innovate and do it better next time. The Army needs leaders that are adaptable and can get through that. But it starts with that all-important foundation of values and ethics.

Gardner: I think we have talked about new equipment and evolving doctrine for the Army. But at the end of the day, the Army remains all about the Soldier. Just as Maj. Gen. Royar highlighted, it is about that foundation. It’s about being physically, mentally, and morally fit because combat is hard. It is not going to get any easier, despite all of these technological advances. You have to be fit to deal with a faster-evolving combat environment.

In addition, teamwork is essential to everything we do moving forward. The technology is evolving at a faster pace, but we can leverage our teammates to overcome the speed traps. It is about relying on each other to accomplish the mission.

Royar: Collaboration is key; not only internally to the Army, but also with our partners.

Hoyle: I am glad we are all thinking in the same way. To paraphrase the Chief of Staff of the Army, if we take care of the people then the people will take care of the mission. When I say people, it is all of our people. We have three components: the Active, the National Guard, and the Reserve. We have our Department of the Army Civilians and we have our fourth component (industry) partners. The future really will require this whole-of-nation approach.

As each Soldier lives and learns the Army values, they also learn different skills. So, I tell young Soldiers to set that foundation, build leadership skills, and take advantage of every opportunity that is presented to broaden their skillset. Diversity of skills and experiences is how you build adaptability.

Gardner: About every 40 years, the Army goes through a really significant doctrinal and modernization change and we are in the midst of that now. It leads to great opportunities for innovation, at all levels, to drive the changes we'll need to continue our overmatch of any potential adversary.

--------------------

Maj. Gen. K. Todd Royar assumed command of the United States Army Aviation and Missile Command on June 10, 2019. As the commander, he leads more than 16,000 Soldiers and civilians in providing aviation, missile and test measurement, and diagnostic equipment sustainment support to the Joint Warfighter to enable readiness. Royar has deployed and commanded units in combat at every echelon from platoon to brigade in support of Operations Desert Shield/Desert Storm, Iraqi Freedom, and Enduring Freedom.

Maj. Gen. Heidi J. Hoyle assumed command of the Military Surface Deployment and Distribution Command in June 2020. She is truly a multi-functional logistician with a diverse sustainment background. Hoyle has served at every level of command, from company command to brigade command, and is now in her third general officer billet. Hoyle's most recent assignment was commandant, U.S. Army Ordnance School.

Col. Gavin J. Gardner assumed the duties of commander of the Joint Munitions Command and Joint Munitions and Lethality Life Cycle Management Command on June 11, 2020. He was commissioned as a second lieutenant in the Ordnance Corps branch, detailed to the Armor Corps in 1992. He earned a three-year Army ROTC Scholarship and is a Distinguished Military Graduate from the University of Georgia with a Bachelor of Business Administration Degree in Production and Operations Management, 1992; Masters of Science Logistics Management from the Florida Institute of Technology, 2002; and Masters of Arts in National Security and Strategic Studies from the U.S. Naval War College, 2014.

--------------------

This article was published in the April-June 2021 issue of Army Sustainment.

RELATED LINKS

The Current issue of Army Sustainment in pdf format

Current Army Sustainment Online Articles

Social Sharing