Author’s note: This article is the second in a four-part series on Tobyhanna Army Depot’s forward support missions.

TOBYHANNA ARMY DEPOT, Pennsylvania – One big happy family is how a depot employee describes his work environment.

Responsibilities for a new, distinctive mission supporting global readiness of complex, networked Command, Control, Communications, Computer, Cyber, Intelligence, Surveillance, and Reconnaissance (C5ISR) systems and capabilities rest squarely on the shoulders of a small cadre of depot specialists and several hundred contract employees. A short time ago, the oversight of a regional support center (RSC) contract was transferred from the U.S. Army Communications-Electronics Command (CECOM) Integrated Logistics Support Center to Tobyhanna Army Depot’s Field Logistics Support Directorate.

There are seven RSC locations strategically positioned around the world, which provide field maintenance for commercial off-the shelf and non-program of record assets, i.e. generators, environmental control units and automated installation entry. The centers are a direct link to the units in the field, according to Trish Kratzer, Tobyhanna’s RSC Management Division chief. Action officers and technical points of contact conduct business from the depot while RSC managers work from geographically-separated stateside and overseas units.

“I find this mission very exciting,” Kratzer said. “It’s a new concept, where we monitor the execution of the contract. Customers come to us with their requirements, we work with the contractor to determine the best way to get the job done.” Feedback from the field has been positive, she added.

RSC Manager Antonius Vasser works with weapon system teams and project/product managers to coordinate and manage support for unit equipment in the Republic of Korea. Skilled technicians respond to the customer’s logistical, mechanical and technical requirements.

Vasser, like his counterparts at other sites, also acts as a contracting officer technical representative (COTR) for the multi-million dollar contract. A source of inspiration for him is the work the team accomplishes on a daily basis.

“I enjoy planning out a new support requirement and working out the process and then putting it into action,” Vasser said. “The people I work with are a great group of professionals dedicated to providing the best support possible to the warfighter.”

Tobyhanna Army Depot started performing contract oversight duties in December 2019. Personnel have remarked on how much they have learned from their experiences supporting the RSC mission.

John Laskowski said he’s always learning something new. The nature of the work generates a lot of job satisfaction, he remarked, adding the service and repair mission makes such a positive impact on the Soldiers in the field.

As an action officer, Laskowski directs customer programs and requirements for all regional support center locations. His duties include managing worldwide customer tracking numbers and customer fielding and field-level repair programs.

“The people in the field are hardworking and team oriented,” he said. “The field support community is a very tight knit group who place Army readiness at the top of their list of priorities.”

Team members claim the managerial position has opened doors to learning project management skills, along with building a great network of customers and peers worldwide.

The RSC managers for Europe and Africa interact with units, government activities and personnel to identify where and how the regional support center can support the warfighter.

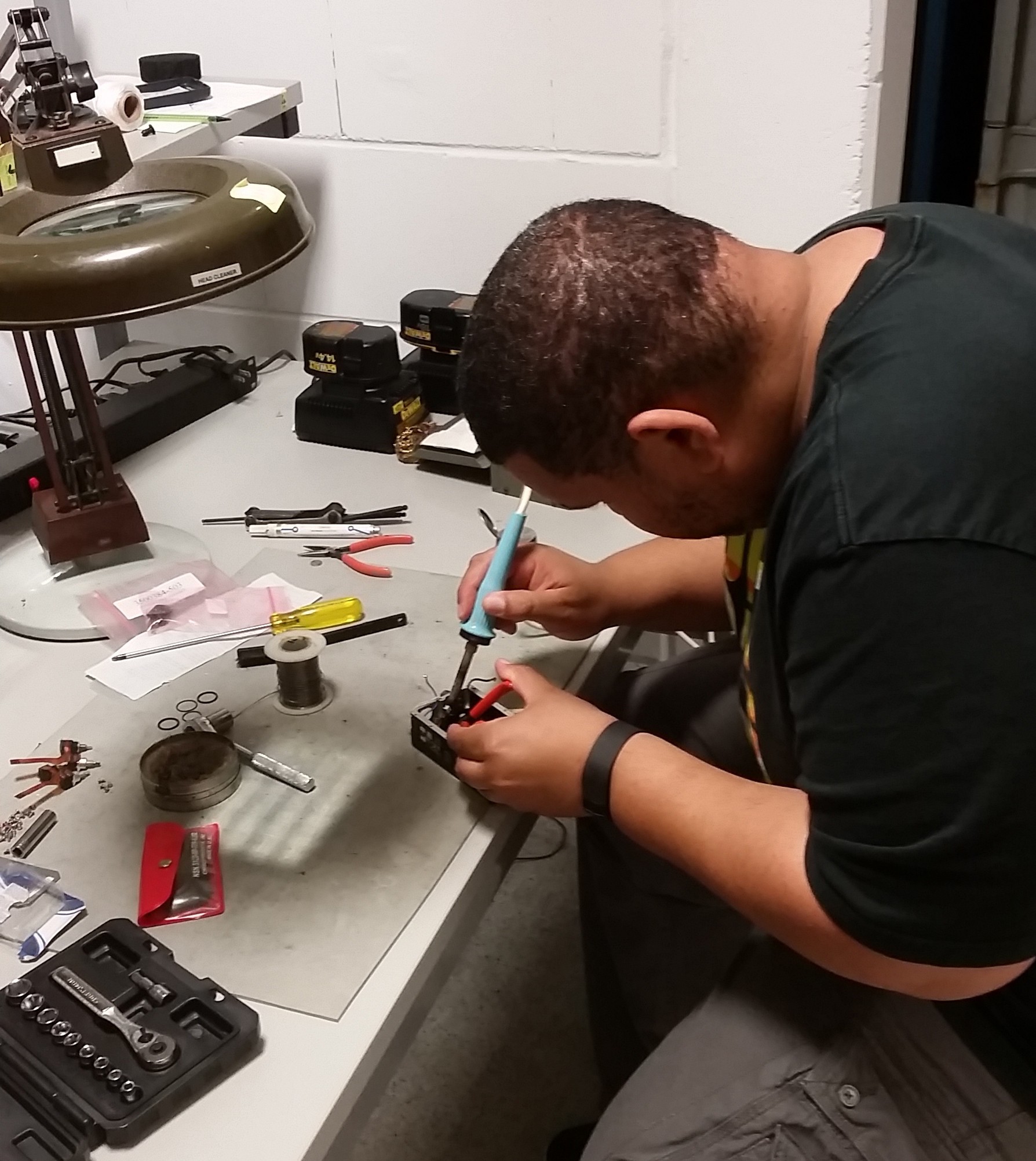

Technicians and logisticians who work on a variety of Army assets from radios to air survivability equipment are well-rounded, trained and equipped with the appropriate tools to support customer needs, according to Robert Martin and Thomas Ironside.

“I love the challenge of the mission and witnessing how the Soldier benefits from the work we perform,” said Ironside.

While working within the RSC framework, Martin said he’s attended multiple training courses detailing logistics management and contracting. Knowledge he said he uses to help the depot succeed.

Money matters for the diverse RSC mission are handled by Financial Coordinator Mark Bell. He works with the customers to get funding for the missions and direct support for the centers. Bell has a passion for working with forward elements.

“I feel we have one of the best teams at Tobyhanna Army Depot,” Bell said. “I’m so proud of the work we do to help the warfighter.”

Alfred Hall leads an RSC team of specialists who provide maintenance sustainment support in the continental United States-East footprint. The facility, similar to other locations, boasts a robust shipping and receiving area that processes assets daily for military sites around the world. In addition to active-duty Army, the support center takes care of National Guard and Reserve assets.

Hall said the best part of his job is the ability to provide timely support and quality maintenance to the warfighter.

“Team members are dedicated to the mission,” he said. “They understand what they do and who they do it for.”

One action officer said his experiences have taught him to be a better person and appreciate the critical role he plays in the success of the RSC mission.

Edward (E.J.) Wrightson welcomes the daily challenge of capturing a customer’s requirements, then working with each RSC manager to achieve customer satisfaction. This mission provides a worldwide sustainment infrastructure that supports over 100 different weapon systems in all major commands, he said.

“I provide customers with logistical support and the flexibility to tailor the required support based on mission requirements, funding and organizational special needs,” Wrightson said. “I am proud of the hard work everyone puts in day to day. Each team member is willing to jump in and help with any issue or situation.”

Since we all started working together, it’s like we’ve become one big family, according to Paul Hoban, action officer.

Social Sharing