In April 2003, 608th Ordnance Company (Ammunition) arrived in Kuwait and retrieved their rolling stock equipment from the seaport of debarkation (SPOD). They were task-organized under 3rd Infantry Division and immediately sent into their formations to support the initial attacks in Iraq. The company had been allocated to the division with one platoon supporting each brigade and the headquarters and one platoon supporting the main support battalion, as they were designed. Upon arrival at the SPOD, the unit had less than 72 hours to prepare to cross the berm into Iraq. With our experience as reference and the context of future large-scale combat operations (LSCO), it is more important than ever to consider strategic readiness as more than the deployment process itself, but rather ending when our units are employed into the theater of operations.

As written in Field Manual 3-0, Operations, “Speed is paramount; force projection is a race between friendly forces and enemy or adversary forces. The side that most rapidly builds combat power can seize the initiative.” Deployment readiness includes routine operations related to commander’s discipline programs, the deployment process, and the ability to rapidly enter the fray in the formation needed to enable operations. Leaders should develop readiness for deployment (getting to the fight) and prepare their subordinate platoons, sections, and teams for employment based on their doctrinally allocated mission (getting into the fight) in order to rapidly generate combat power and join the fight. Many companies will be employed by allocating a platoon, section, or team to a supported unit just as Field Feeding Teams support functional brigades and as Heavy Equipment Transport (HET) companies may allocate a platoon to an Armored Brigade Combat Team.

Force Projection is the U.S. Strategic Advantage

The importance of deployment readiness as a strategic advantage is captured in the introduction of U.S. Army Training and Doctrine Command Pamphlet 523-3-1, The U.S. Army in Multi-Domain Operations (MDO). It states, “As a nation, we rely on our ability to project power from the Continental United States and to integrate the actions of the Joint Force globally. Our adversaries seek to fracture this capability and erode the United States’ strategic advantage—the greatest challenge to U.S. security, power, and influence to emerge in the 21st century.” Our strategic advantage is rooted in the basics of daily deployment readiness operations, which should be informed by how a unit is employed and can be integrated into unit training, supply, maintenance, and administrative operations. The Command Deployment Discipline Program establishes the minimum requirement and metrics that are applicable to the entire force; but commanders are encouraged to tailor, and add to, this program to meet their specific mission needs. Commanders at all echelons must treat deployment readiness like combat readiness, ensuring all metrics are above an acceptable state.

Preparation for Future Large-Scale Combat Operations To demonstrate why readiness for deployment and employment matters, we refer back to the MDO concept and a commander’s charge in Army Regulation 600-20, Army Command Policy. “In the MDO construct, expeditionary forces must be able to deploy, employ, and gain a position of relative advantage within days or a few weeks of alert. "The implication here for all unit commanders is the reinforcement of their responsibilities explicitly explained in Army Command Policy: The commander is responsible for ensuring “both Soldiers and equipment are in the proper state of readiness at all times” and developing “disciplined and cohesive units sustained at the highest readiness level possible.” Readiness levels are truly tested beyond home-station missions and preparing for deployment as a strategic move.

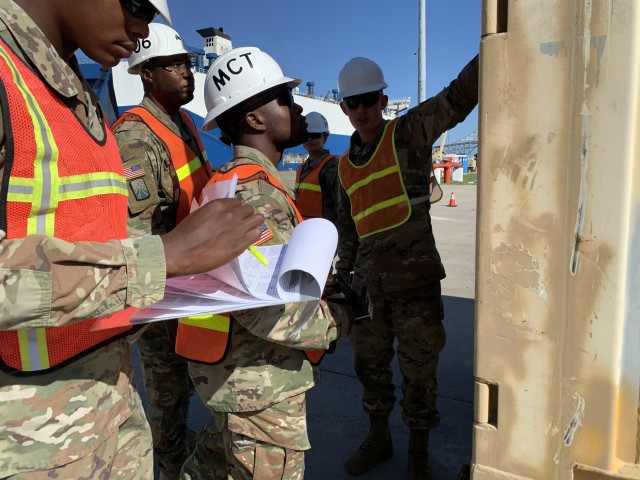

In 1st Armored Division, units periodically conduct deployment readiness exercises. These events challenge units to efficiently and effectively move their personnel and cargo from the unit staging area to the strategic deployment node; pass inspections by either the local Movement Control Team or Logistics Readiness Center; and be loaded onto a mock-up or actual transportation mode.

On March 11, 2019, 1st Battalion, 6th Infantry Regiment, was in the middle of gunnery exercises in El Paso, Texas, when the call came in from division headquarters to deploy to Poland. A week later, 1,500 brigade Soldiers were bound for training grounds in western Poland for a deployment reminiscent of the Cold War, when no-notice mobilizations were a main feature of the military’s strategy for countering the Soviet Union. Commanders have to understand, anticipate, and set conditions for how their unit is most likely to be deployed and employed.

Commanders’ considerations of how the formation is employed drives discussions about how equipment is stored, maintained, sub-hand receipted, and packed. The speed of which we are able to employ our forces matters nearly as much as how fast we can move them. There may no longer be lengthy build-up periods or deterrence operations as units react to competitor aggression. In MDO, “Army expeditionary forces deploy from the homeland and other regions using joint strategic transportation and arrive at multiple points in theater, proceed forward along multiple routes, and then occupy dispersed tactical assembly areas within range of enemy anti-access and area denial systems.” Units may not be afforded the time or uncontested space to unpack large containers and reconfigure into the desired equipment package needed for the mission. Unit commanders should start suborganizing equipment (and hand receipts), containers, prime movers, secondary loads, and ancillary equipment while at home station; and reinforce this alignment during training. Unit Movement Officers must ensure their due diligence in building plans in the Transportation Coordinators’ Automated Information for Movement Systems Version II (TCAIMSII) that reflect their organization equipment list and later their unit deployment list.

One example for consideration is the modular ammunition ordnance company employment. A modular ammunition ordnance company normally consists of a headquarters platoon and three modular ammunition platoons, with the command and control capacity to expand to five. The modular ammunition ordnance company also includes a modular ammunition rough terrain container handler (RTCH) augmentation team, which may also be expanded as required. Due to the modular construct of the modular ammunition ordnance company, each platoon assigned can independently deploy and execute ammunition operations. An ammunition ordnance platoon is an element with a three-person leadership team, ammunition inspectors, a stock control noncommissioned officer, ammunition handlers, and a RTCH team.

Each modular ammunition platoon can be employed in separate locations to conduct port operations, singularly execute ammunition supply point activities, or combine platoons to facilitate corps and theater storage area munitions operations. Each platoon requires the capability to communicate with the company leadership team via voice and data despite geographic dispersion. Aligning personnel is relatively straight forward for the equipment operators. However if the platoons are dispersed, the commander should ensure supply, maintenance, movement, and administrative capabilities exist with that platoon. It would increase unit velocity in building combat power to maintain these capabilities on a daily basis at home as we would in the employed environment.

The modular ammunition ordnance commander should routinely subhand receipt the platoon equipment to the platoon leaders, who will further sign the equipment to subordinates in order to maintain accountability. An overlooked area in several units is aligning, sub-hand receipting, and packing ancillary equipment such as weapons, night vision devices, tents, generators, radios, ammunition tool kits, and battle command systems. Packing sub-echelon equipment as its employable module using triple containers or quadruple containers, as opposed to one 20-foot military-owned, demountable container—known as a MILVAN—for company-level equipment movement and storage facilitates rapid employment of the modular ammunition platoon. Storage, accountability, and transportation of equipment aligned to mission sets reduces reconfiguration actions at the intermediate staging base or tactical assembly area.

The additional step that saves time and frustration in the deployed environment is requesting derivative unit identification codes (UICs) at home station; and aligning the storage locations (SLOCs) and UICs in Global Command Support System-Army to the element or unit most likely to be operating semi-independently. The platoon must ensure they maintain 30 days of shop stock listing and bench stock listing while sustaining monthly inventories and ensuring stocks are mobile for rapid movement. This enables maintenance management, repair parts flow, and supply accountability at the lowest level.

Employment Readiness Applies to All Sustainment Formations

Elements of a sustainment brigade deploy differently than brigade combat teams (BCT). BCTs normally move as entire units. The organic brigade support battalions (BSB) and forward support companies (FSC) also conduct strategic movements as entire units. However, even though an FSC deploys as a company, it still gets further segregated even in a battalion fight. The FSC has company train command posts (CTCP) and unit maintenance collection points (UMCP) that may not be collocated. The CTCP’s vehicles, tent, generator, radios, and additional support equipment can be hand receipted to the platoon leader who is going to be in charge of the CTCP. Everything can be staged together in the motorpool for efficient load out. In the same manner, UMCP equipment including the M88 Hercules armored recovery vehicle, toolboxes, Command and Control Vehicle, weapons, radios, tents, generators, and diagnostic equipment can be on the maintenance platoon leader’s hand receipt; and appropriately stored and staged for how it will be deployed and employed.

Further back on the linear battlefield, the BSB operates the field trains command post, ambulance exchange points (AXP), and the brigade support area. All three units may not be collocated. Thus, each of their equipment sets should be hand receipted to the correct people in the task organization for each activity. Each activity’s equipment set should be parked and staged together in the motorpool for efficient load up and roll out to be employed in the field. For example, the ambulance platoon leader should sign for all the AXP equipment which should be staged in the motorpool with the two ambulances. Every mission won’t be the same, but staging vehicles and equipment for a roll out off a baseline with consideration for how they are actually employed in the field is much easier to tweak for missions than if they’re assigned and staged without thought to how the equipment will actually be employed. The concept of preparing readiness for employment can be applied to all sustainment formations of all functions.

Rapid Employment is an Operational Advantage

Our military culture today is a byproduct of persistent limited contingency operations spanning over 18 years that are heavily dependent on theater-provided equipment. Historically, battlefields in LSCO have been more chaotic, intense, and highly destructive than those the Army has experienced in recent decades. It is imperative to consider strategic readiness as more than the deployment process, but as an operation ending when our units are employed into the theater of operations. The Deployment Process Modernization Office’s Deployers Toolbox (found on the U.S. Transportation Corps website) is a dynamic online source of deployment and redeployment information and products offering the most current handbooks, pamphlets, standard operating procedures, lessons learned, best practices, and trends. T he Sustainment Virtual Playbook, maintained on the Combined Arms Sustainment Command Sustainment Unit One Stop website, also provides an overview of the difficult tasks conducted during Reception, Staging, Onward Movement, and Integration (RSOI) to shape commanders’ understanding of the initial phase of employment. Deployment readiness is an initiative that has to be practiced and monitored every week. It capitalizes on routine operations related to commander's discipline programs, the deployment process, and the ability to rapidly integrate into theater operations in the formation needed to enable operations and sustain readiness.

-----------------------------

Col. Ronnie Anderson currently commands the 1st Armored Division Sustainment Brigade deployed to Bagram, Afghanistan, in Support of Operations Freedom's Sentinel and Resolute Support. He holds a master’s degree of Strategic Studies from Marine Corps University and a master’s degree of Logistics from Florida Institute of Technology.

Maj. Rich Martinez is the executive officer for 1st Armored Division Resolute Support Sustainment Brigade, Afghanistan in support of Operation Freedom’s Sentinel and Resolute Support. He holds a bachelor's degree from Texas A&M International University and a master’s from Clarkson University.

Capt. Eli D. Rothblatt is the detachment commander for 606th Movement Control Team, 142nd Combat Sustainment Support Battalion, 1st Armored Division Sustainment Brigade. He has a bachelor’s degree from Johns Hopkins University and a juris doctor from New York University School of Law.

-----------------------------

This article was published in the April-June 2020 issue of Army Sustainment.

RELATED LINKS

The Current issue of Army Sustainment in pdf format

Current Army Sustainment Online Articles

Social Sharing