Imagine an Armored Brigade Combat Team (ABCT) with an operational readiness (OR) rate on combat platforms over 95% for 12 months. Imagine over 80% of the combat platforms in an ABCT successfully participate in the brigade live-fire training exercise at the National Training Center, Fort Irwin, California. Imagine over 99% of all M1A2 system enhancement package tanks and M2A3 Bradley infantry fighting vehicles arrive to a combatant command ready to fight and win. “Imagine” is not just the most powerful word in the English language. The 3rd Armored Brigade Combat Team (ABCT), 1st Cavalry Division (3/1 CD), known as “Greywolf,” has transformed its operational readiness to more than 95% on combat platforms, resulting in nearly all of its M1A2 system enhancement package tanks and M2A3 Bradley infantry fighting vehicles arriving at combatant commands ready to fight and win. “Imagine” is a word that has transformed Greywolf into one of the most lethal armored formations on planet earth.

Maintaining a high OR rate in an ABCT is challenging under the Army’s Sustainable Readiness Model (SRM). Units often struggle to navigate the uncertainty of a high operational tempo, personnel, and leadership changeovers, aging systems, and the competing demands that consume Soldiers’ time. The greatest challenge is the limited experience with and working knowledge of Global Combat Support System-Army (GCSS-Army). Critical maintainers assigned to ABCTs often arrive with no prior experience in these formations, which exacerbates the existing knowledge gap. As a result, it is incumbent on the unit to develop a comprehensive leader development program that trains and certifies the entire brigade maintenance Enterprise.

Maintaining an ABCT fleet is challenging in the current environment; however, improving a unit’s fleet to meet the Army’s 10-20 maintenance standard is an even greater task. To achieve this task, leaders must become experts in the eight components of 10-20 outlined in Army Regulation (AR) 750-1, Army Materiel Maintenance Policy, paragraph 3-2.

The first step to build the culture and systems to achieve the 10-20 maintenance standard is understanding the requirements. Once all leaders in the unit understand 10-20, the unit’s maintenance Enterprise must develop and implement a methodology that effectively resources, executes, and accounts for each component of 1020. To maintain or achieve 10-20, commanders at echelon must:

• Establish unit priorities

• Give maintenance guidance

• Conduct leader and technical certification

• Develop tracking and inspection mechanisms for the program

• Embed these elements within the unit’s culture and standard operating procedures (SOP) as routine processes

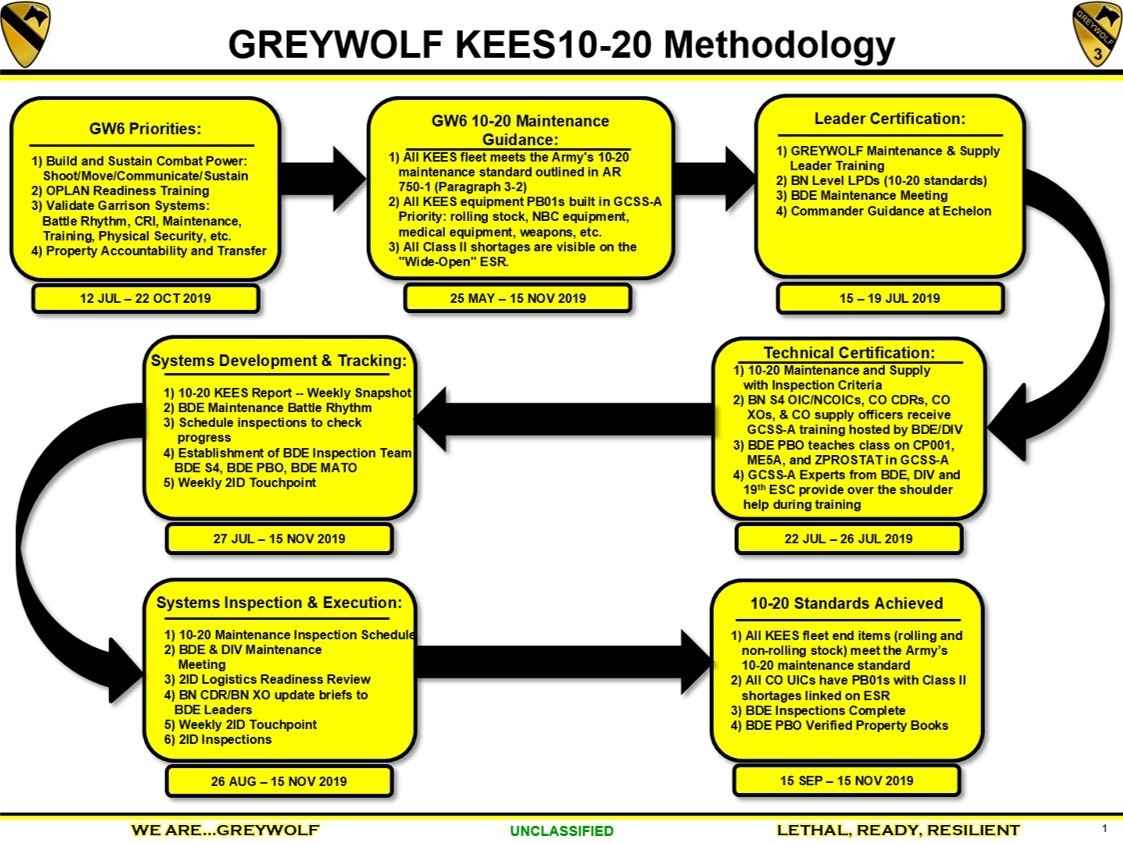

This paper outlines the methodology used by 3/1 CD to improve the unit’s maintenance posture to 10-20 in preparation for their deployment to the U.S. Indo-Pacific Command (INDOPACOM) area of operations. Using this methodology, Greywolf successfully delivered U.S. Forces-Korea (USFK) the most ready ABCT ever to arrive on the Korean peninsula; specifically, the brigade delivered over 99% of their organic combat platforms ready to Fight Tonight. Subsequently, Greywolf began resetting the armored brigade Korea enduring equipment set (KEES) to 10-20, applying the lessons learned at Fort Hood to further improve their maintenance Enterprise’s systems and processes.

Establishing Unit Priorities and Maintenance Guidance

In order to develop Greywolf’s maintenance priorities and guidance, the brigade commander and senior leader in the maintenance Enterprise reviewed 1st Cavalry Division’s (1CD) operational framework through a maintenance lens.

In addition to these priorities, 1CD commander’s annual training guidance (ATG) outlined the expectation of subordinate commanders to strive for excellence in the Command Supply Discipline Program (CSDP), maintenance, administrative processes, and leader development. These two sources informed the development of the brigade commander’s guidance to the brigade maintenance Enterprise prior to deployment:

• Greywolf 10-20 maintenance guidance

• Develop a comprehensive plan and detailed methodology

• Develop services and 10-20 maintenance book

• Develop reporting requirements

• Establish weekly touch points (brigade/division)

• Establish a certification program

• Establish a Quality Assurance/Quality Control Team & checklist

The commander’s maintenance guidance framed the brigade maintenance enterprise’s efforts across three lines:

• Certification

• Reporting

• Inspection

• Quality control

Leader and technical certification, standardization and construction of the GWBs, and the brigade inspection team guidance were then sequenced to enable subordinates to execute. The progress of the guidance was relayed to the brigade commander through small working groups; the initial prioritization was given to leader and technical certification; the commander’s guidance was updated when the unit arrived in the Korean Theater of Operations:

• GW6 10-20 maintenance guidance (KEES)

• All KEES fleets meet the Army's 10-20 maintenance standard outlined in AR 750-1 , paragraph 3-2

• All KEES work orders (PB01s) built in GCSSArmy. Priority: rolling stock; nuclear; biological, and chemical equipment; medical equipment; weapons; etc.

• All Class II and Class IX supply shortages are visible on the “wide-open" equipment status report

The most notable difference in this second set of guidance is the brigade commander’s focus on PB01s; this metric was determined to be the best measure of performance in the execution of a 10-20 maintenance program. This shift to a more explicit form of guidance was enabled through the leader and technical certification conducted by the brigade maintenance enterprise.

In both cases, the commander’s guidance, informed by his senior maintenance personnel, served to direct the brigade maintenance Enterprise’s efforts and underwrite the costs of implementation. Additionally, effective communication with higher headquarters further reduced friction caused by competing demands on the unit.

Conduct Leader and Technical Certification

As the brigade developed its leader and technical certification courses, it became clear that there was a significant GCSS-Army knowledge gap for leaders and operators alike. It is alarming to learn that unit supply specialists (92Y) and automated logistics specialists (92A) only receive approximately 40-80 hours of GCSS-Army training during their advanced individual training (AIT). It is incumbent upon the unit to develop their junior Soldiers and noncommissioned officers through a deliberate leader development strategy aimed at very specific outcomes. The expertise required to teach this level of GCSS-Army knowledge is most often found within the collective knowledge of the entire warrant officer community in an ABCT; therefore, the brigade maintenance enterprise developed a curriculum that enabled leaders at echelon to monitor the 10-20 maintenance status in their respective organizations.

Once the brigade commander’s 10-20 maintenance guidance was distributed, the brigade maintenance enterprise developed a 10-20 certification course for company and battalion-level leaders. The purpose of the certification course was to teach the intricacies of the systems in Army’s maintenance programs. More specifically, the course was designed to teach leaders how to ask the right questions when it comes to GCSS-Army. Leaders were shown how to access GCSS-Army and pull the reports required to track the 10-20 progress of their organization.

The certification course consisted of an overview of:

• 5988E: Execution and routing at the battalion level

• Equipment status report (ESR): How to read the ESR and learn variations

• Plant 2000/2001 reference document numbers

• Maintenance plans/services

• Modified work orders/Safety of use messages

• Bill of materials (BOMs) and shortage annexes

• Work order (PB01)

• Display of Purchase Requisition Training (ME5A) and order status reports (ZPROSTAT)

• Parts tracking (FedMall, webvlips, and integrated global convergence)

One key takeaway for all leaders in the 10-20 Certification Course is the ability to link PB01s built by 92Ys in company supply rooms to the ESR by 92As in the maintenance shop. The result of this process is what the brigade refers to as the "wide-open ESR." This ESR shows all Class II and Class IX supply shortages in one document under each unique bumper number. The ability to link PB01s to the ESR allows company commanders to view their CSDP Program and command maintenance program in one coherent document; it allows them to simultaneously inspect their company per AR 750-1 and AR 735-5, Property Accountability Policies. Prior to this certification course, the brigade did not understand how to easily view Class II and Class IX shortages. Through the intrapreneurship of junior leaders, the brigade maintenance Enterprise learned that PB01s could be linked. This key finding allowed Greywolf to push the limits of what had previously been done; it also enabled a shared understanding across the division that was not previously realized.

Once complete with leader certification, the brigade maintenance Enterprise focused on developing a technical course for 92Ys and 92As. To develop a viable curriculum, Greywolf established two key outcomes for the course. The first outcome was that all shortages would be properly documented on a shortage annex (BOM) with valid requisition numbers. The second outcome was that all shortage annexes would have individual PB01s built per vehicle and linked to the wide open ESR.

Specific items for technical certification that Greywolf developed to meet desired outcomes include:

• Technical certification (prior to deployment)

• 10-20 Maintenance Inspection Team with inspection criteria

• Division G4 hosts GCSSArmy training for battalion S4 (logistics) officers in charge (OIC)/noncommissioned officers in charge (NCOIC), company commanders (CO), company executive officers (XO), and company supply officers

• Brigade property book officer (PBO) teaches class on CP001, ME5A, and ZPROSTAT in GCSS-Army

• GCSS-Army field service representatives provide over-the-shoulder help during training (III Corps/1CD)

• Technical certification (KEES)

• 10-20 maintenance and supply with inspection criteria

• Brigade/Division hosts GCSSArmy training for battalion S4 (logistics) OIC/NCOIC, CO, XO, and company supply officers

• Brigade PBO teaches class on CP001, ME5A, and ZPROSTAT

• GCSS-Army experts from brigade, division, and 19th Expeditionary Sustainment Command provide over-the-shoulder help during training

Systems Development, Tracking, and Inspection

In order to accurately track and report the 10-20 status of the vehicle fleet, Greywolf developed a set of reports and tracking mechanisms for the commander to set priorities and allocate resources. The brigade also created an inspection team that could be used to validate and verify the 10-20 progress of the organization.

Some of the tools Greywolf used include:

• Brigade and battalion maintenance meetings

• The brigade maintenance enterprise developed a standard battle rhythm with two brigade meetings and one battalion meeting per week

The following items are discussed in every maintenance meeting:

• Materiel maintenance officer notes/Division notes

• “X” ESR for all vehicles

• Standard pricing/Overaged Repairable Items Listings for credit and non-credit

• All scheduled services

• Army Oil Analysis Program and Test Measurement and Diagnostic Evaluation validation

• Maintenance management information system (Modified work order/Safety of use message) validation

• 10-20 Weekly Report/ Snapshot. The 10-20 Weekly Report is a table-based report of every vehicle in the brigade. Each vehicle has its own row with at least eight corresponding columns. The columns cover the eight components of the Army’s 10-20 standard outlined in AR 750-1. Additional columns can be added at the commander’s discretion.

The GWB is a binder with the following documents:

• Current 5988E and wide-open ESR

• Current shortage annex using the BOM from GCSS-Army

• Maintenance plan/Service packet

• ZPROSTAT

• Updated technical manual

• Current hand receipt page

• Clear modified work order printout from Modification Maintenance Information System

• U.S. Army Tank-automotive and Armaments Command Unique Logistics Support Applications (TULSA) gun card

• Current Army Oil Analysis Program report

• List of all special tools

The Brigade Inspection Team (BIT) is comprised of maintainers in the top 10% of their military occupational specialty throughout the brigade. The BIT officer in charge is the brigade’s best maintenance technician. The officer in charge has two subordinate noncommissioned officers with expertise on the most critical vehicle fleets within the brigade.

In order to be part of the BIT, members must:

• Pass an initial screening

• Be recommended by their chain of command

• Conduct an interview with selected senior leaders

Once the team is finalized, they validate:

• Wide-open ESRs

• Technical vehicle inspections and service packets

• GWBs Vehicle predeployment checklists; the actions of the crew

• Vehicles during transit between duty locations

Scheduled inspections, briefings, or required updates enabled shared understanding and allowed commanders to identify risks as well as communicate any issues or resources needed to meet 10-20. The brigade maintenance Enterprise outlined the following touch points to provide constant updates:

• Execute the published 10-20 standards inspection schedule (BIT validates data in GCSSArmy, TULSA, etc.)

• Biweekly 10-20 update at division maintenance meetings and division logistics readiness reviews

• Battalion commander monthly update brief to brigade commander

• Brigade maintenance Enterprise monthly update brief to the deputy commanding general-support (DCG-S)

• Weekly or biweekly written closeout reports to the DCG-S, brigade commander, sustainment brigade commander, division G4, and division material maintenance officer

10-20 Standards Achieved: What Success Looks Like

At the conclusion of the process, units must be able to validate key tasks to determine if the methodology helped meet the Army’s 10-20 Maintenance Standard, such as:

• All company level unit identification codes have PB01s with Class II and Class IX supply shortages linked on ‘wide-open’ ESR.

• All company commanders must have binders with printed property books and signed subhand receipts

• Shortage annexes with valid requisitions

• The entire company wide-open ESR Brigade inspections complete (inspections are ongoing at prescribed intervals)

• Brigade PBO verifies property books (property books are reverified for every company change of command)

Once a company reaches 10-20, it is incumbent on the brigade maintenance enterprise to ensure the standard is maintained. There are a few options to consider in order to weave this process into the fabric of the organization. First, units must make the company change of command in-briefs and out-briefs an opportunity to inspect the 1020 status of an organization. The wide-open ESR and the current ZPROSTAT must be verified against the shortages identified in the inventory period. Second, the BIT must be a tool the brigade commander can utilize at any moment in time. Lastly, the brigade maintenance enterprise must run quarterly leader and technical certification courses. Leader development is critical; knowledge is the gap units must close.

Chasing Perfection, Finding Excellence

Maintaining a 10-20 fleet under the Army’s SRM is challenging and resetting a vehicle fleet to 10-20 can seem impossible. To maintain or achieve the Army’s ‘10-20 Maintenance Standard’, commanders at echelon must establish unit priorities, give maintenance guidance, conduct leader and technical certification, develop tracking and inspection mechanisms for the program, and embed these elements within the unit’s culture and SOPs as routine processes.

Building a 10-20 vehicle fleet is meticulous, tedious work that requires attention to detail. Moreover, building a 10-20 vehicle fleet requires the support of the brigade commander as well as that of senior leaders in the division. The commander sets priorities and subordinates execute to meet the deadlines. Throughout the process, units resist the urge to skip or cancel any of the touch points within the brigade or from the brigade to a higher headquarters. Lastly, all units must report accurate data. During this process, it is likely that the information being collected and presented is not pleasant and potentially embarrassing. Weather the storm. As long as the appropriate level of funding is available, following this methodology will enable you to meet the Army’s 1020 Maintenance Standard.

------------------------

Maj. Allen M. Trujillo is the brigade executive officer for 3rd Armor Brigade Combat Team, 1st Cavalry Division, at Fort Hood, Texas. He has served as company commander, 4th Battalion, 6th Infantry Regiment, 4th Brigade Combat Team, 1st Armored Division, at Fort Bliss, Texas, and has served two tours in Iraq and Korea. He holds a bachelor’s degree in Systems Engineering from the U.S. Military Academy and a master’s degree in Operations Research/ Industrial Engineering from University of Texas at Austin.

-------------------------

This article was published in the April-June 2020 issue of Army Sustainment.

RELATED LINKS

The Current issue of Army Sustainment in pdf format

Current Army Sustainment Online Articles

Social Sharing