The United States Army's modernization strategy has one focus: make Soldiers and units more lethal to win our nation's wars, then come home safely. Tobyhanna Army Depot is constantly striving to stay in line with those efforts to leverage commercial innovation, as well as cutting-edge science and technology--ensuring accountability, transparency and responsible stewardship of our nation's resources.

The Systems Integration and Support (SIS) Directorate has the largest hiring plan that the depot has seen in over 10 years, according to deputy director, George Bellas. Modernization throughout these facilities is vital to the directorate's mission combined with these continuously growing numbers.

"We have hired 171 new employees in the past year and plan to hire about 100 more," says Bellas.

SIS provides overhaul and special fabrication support to Tobyhanna's mission by preforming electrical and mechanical fabrication, assembly and testing of a wide variety of Command, Control, Communications, Computers, Intelligence, Surveillance and Reconnaissance (C4ISR) systems.

The directorate has a broad base of equipment across multiple shops. As workload continues to increase, so has the demand on equipment supporting depot overhaul operations. Increased workload for programs such as Blue Force Tracking kits, helmet brackets, and general fabrication support for large shelter programs such as Electronic Shop Vans (ESV) and Armament Repair Shop Sets (ARSS) have all increased equipment utilization.

As with any machinery or equipment, there are predictable lifespans. Some equipment sets are now in need of replacement. The depot's approach to forward planning when it comes to modernization strategy has helped to support this need, with plans to replace equipment every year. Scheduling these efforts properly allows for customer costs to stay competitive. In fiscal year 2019, Tobyhanna will be replacing milling equipment, metal saws and welding equipment.

Much of the modernization within SIS has created a need for increases in employee development. For both existing employees and new hires, training is critical to ensuring workplace safety and efficient productivity.

"We've got talented people here, and keeping them up to date with new equipment purchases and training is the key to growing our business," said Paul Borosky, director of SIS.

Another driver of modernization at the depot is the evolution of customer requirements.

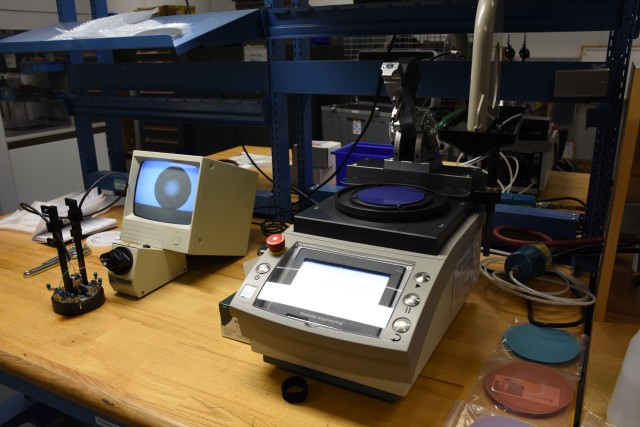

In SIS, there is a need for development of new technologies to fabricate and overhaul customer requirements. For example, only a few relatively small customer programs exist using fiber optic technology at the depot--so few that customers that visited in the past year were surprised to discover this capability was available.

As a result of increased customer requirements, new fiber optic cable polishing equipment has been purchased to prepare for potential growth. Training has also been contracted to help enhance the skills of employees within the Electronics Fabrication Division of SIS.

Another modernization effort in SIS is projected to begin this month and will capitalize on recent LEAN Model Cell awards for Team Tobyhanna's ESV and ARSS programs.

The plan is to consolidate similar shelter lines, creating a multifunctional workspace that will allow employees to most efficiently perform shelter work for all joint service customers by sharing best practices in one location.

"Construction for this project is expected to take a year to complete," added Ronald Scarnulis, lead industrial engineer at the depot.

Modernization efforts such as these will continue to allow Team Tobyhanna to increase readiness and provide the best value to the warfighter.

Tobyhanna Army Depot is a recognized leader in providing world-class logistics support for command, control, communications, computers, intelligence, surveillance and reconnaissance systems across the Department of Defense. Tobyhanna's Corporate Philosophy, dedicated work force and electronics expertise ensure the depot is the Joint C4ISR provider of choice for all branches of the Armed Forces and industry partners.

Tobyhanna's unparalleled capabilities include full-spectrum logistics support for sustainment, overhaul and repair, fabrication and manufacturing, engineering design and development, systems integration, post production software support, technology insertion, modification, foreign military sales and global field support to our Joint Warfighters. About 3,200 personnel are employed at Tobyhanna, which is located in the Pocono Mountains of northeastern Pennsylvania.

Tobyhanna Army Depot is part of the U.S. Army Communications-Electronics Command. Headquartered at Aberdeen Proving Ground, Maryland, the command's mission is to research, develop, acquire, field and sustain communications, command, control computer, intelligence, electronic warfare, and sensors capabilities for the Armed Forces.

Social Sharing