Intelligent automation in the corporate arena is changing the landscape of business. One by one, major corporations such as Walmart, Amazon, Microsoft, and Google are integrating automated command systems and platforms into their infrastructures in order to increase efficiency. Daily level-one tasks handled by individuals using large enterprise-based software applications are now being automated through multiple platform-based tools that allow businesses to save time and money.

Digital in nature, intelligent automation is defined as a combination of artificial intelligence and automation, which is traditionally housed in an enterprise-level software application. Intelligent automation is an advanced form of robotic process automation, which mimics basic tasks such as data entry.

As intelligent automation makes waves in the corporate civilian sector, how automation tools will be applied within the Department of Defense (DOD) remains to be seen. The heightened level of risk in the DOD allows for zero margin for error. Since the technology is fairly new, the DOD is still skeptical of potential compromise through espionage or cyberattacks.

As competition grows on the international spectrum between superpowers, the U.S. military has gradually adjusted and pivoted priorities to modernize the operational force. The recent stand-up of cyber commands across military branches as well as the Army Futures Command, speaks to a willingness to adapt to the battlefields of tomorrow.

Unfortunately, procurement, research, development, testing, and evaluation have fallen drastically during the past decade because of cyclical drawdowns in modernization funding according to the Total Obligation Authority. The root cause for the decline in modernization is linked to the phase-out of Future Combat System research and development efforts and inefficiency of some larger scale programs.

Despite the shortfalls that the Army has faced with research and development, I believe that there are opportunities to use intelligent automation across multiple branches to increase efficiency of operations throughout logistics commands. Adopting large intelligent automation for enterprise operating systems similar to SAP is a cost-efficient path toward saving the Army time and assets.

As a logistics officer, I see multiple opportunities to implement automation applications within the Logistics branch. In my four years in the Army National Guard, I spent two years as a motor transport operator and two years as a transportation officer. Within the enlisted corps, I found that many Soldiers are responsible for tasks that could be automated, which would allow Soldiers to expand their effectiveness throughout different areas of the Logistics branch. Implementing intelligent automation applications into the Army's infrastructure could increase efficiency.

GCSS-ARMY

The Global Combat Support System-Army (GCSS-Army) is used to order repair parts, log deficiencies, update and issue licenses, and record issues for future equipment repairs. GCSS-Army replaced the old Standard Army Maintenance System-Enhanced (and other logistics information systems) to provide a more user-friendly, timely, and accurate interface for Soldiers to synchronize the flow of materials on the battlefield.

GCSS-Army is split into two separate components: the GCSS-Army Enterprise Resource Planning (ERP) solution and the Army Enterprise Systems Integration Program (AESIP). The ERP component uses a basic form of automation and allows logistics managers to control the flow of logistics throughout their organizations. AESIP acts as a data bank that stores battlefield and garrison data for force projection in arming, fixing, fueling, sustaining, and completing tactical logistics financial processes.

The implementation of GCSS-Army is intended to increase efficiency, but it still does not fully embrace the potential of larger scale automation solutions. Intelligent automation can improve the effectiveness of GCSS-Army in the areas of supply tracking and forecasting, transition of property, and maintenance data regulation.

SUPPLY TRACKING AND FORECASTING

Tracking the supplies and providing real-time data support to units who have put in orders is not readily available in the status quo. This causes friction as units are continually checking in with the distributor on the status of the supply. Allowing units to receive system updates on the status of the supplies from the supplier is critical to effective supply chain management best practices.

Intelligent automation can be used to forecast the needs of the customer unit for future operations based on the pattern of supply requests or through pre-requested supply inquiries. These patterns of supply requests can be created through machine learning or process automation and would allow units to get their supplies on time and ahead of schedule. Thanks to an algorithm built into GCSS-Army, units no longer need to manually monitor, forecast, audit, and manage future requests and fulfillment between customers and suppliers.

Additionally, intelligent automation is being used as a financial forecasting tool for businesses to manage expenditures, revenue streams, and payrolls and to conduct break-even analyses. With the automated pattern recognition of customer units' purchase history, the Army will be able to project further allocation of unit funds ahead of time. Implementing such pattern recognition software will also allow for smart purchasing decisions in order to make the most out of strategic purchases for unit mobility.

TRANSITION OF PROPERTY

In every chain of command, the transition of property is a tedious process for an important reason. Managing property statuses is a manual process that requires cataloging in GCSS-Army for tracking purposes. Tracking the status of property could be managed using an intelligent automation process that originates when the property is first entered into the property book in GCSS-Army.

However, the user interface for GCSS-Army makes it difficult for a commander to actively track equipment effectively. Allowing for a categorical and user-friendly interface that assists commanders when conducting a property transition may be the answer for increasing the efficiency of a change of command property handoff.

MAINTENANCE REPORTING

Machine learning is one of the primary methods for developing an automated infrastructure protocol for automated systems. Infrastructure developers tend to use a testing framework, which allows the automation system to run a series of tests. The outcome of each test dictates the direction of the application.

Within the testing framework, metadata that comes through the system goes through this series of tests and is then acted on by the system based on the result. An example is automated information security; intelligent systems automate a series of tests to determine if a threat is imminent or if it is a false positive security threat.

DEEP LOGIC TESTING NETWORK EXAMPLE

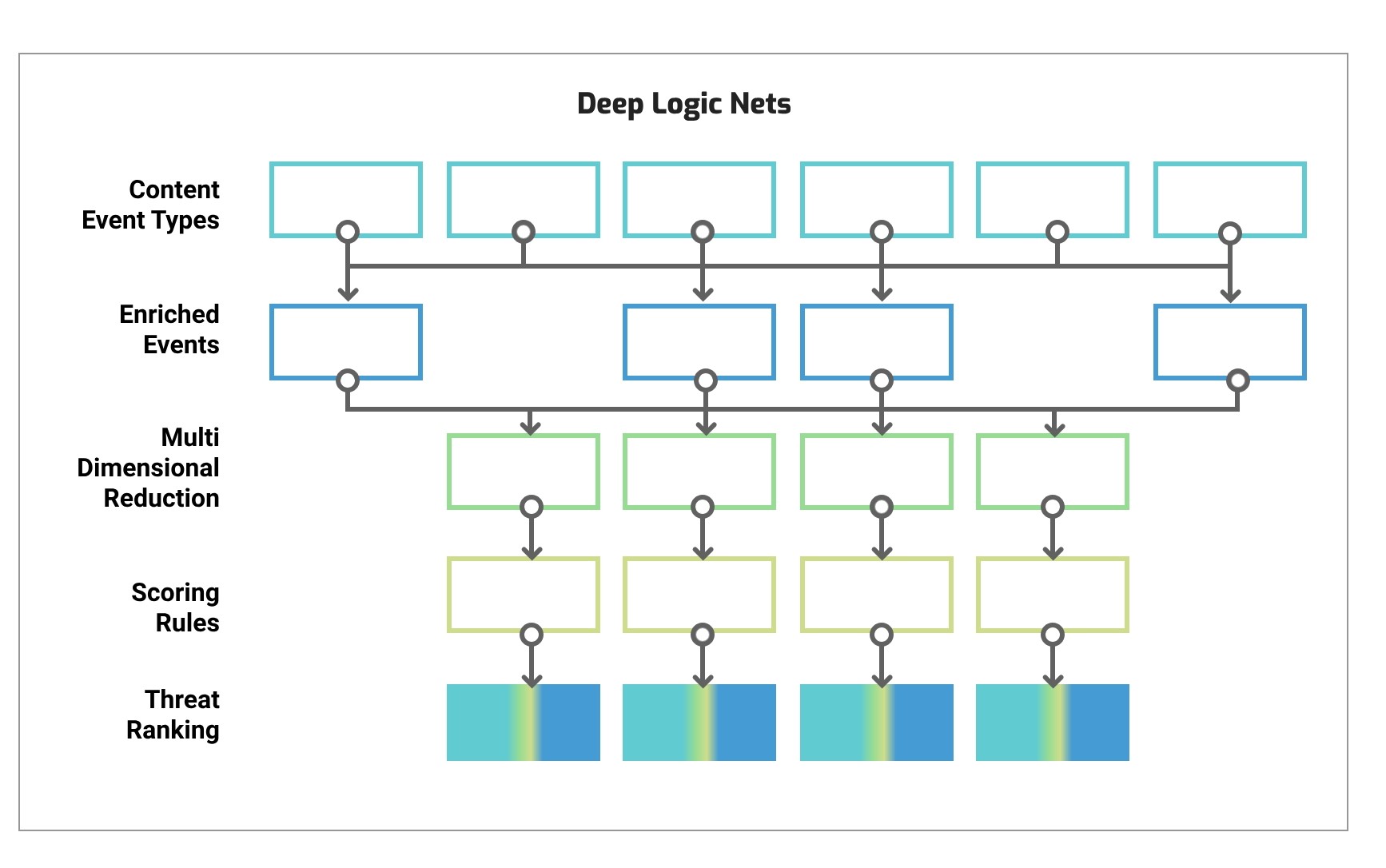

Figure 1 represents a process for an intelligent automation network that runs a cyberthreat through a series of event types and then scores the threat based on the result of each event type. Once a threat has been scored, it is assigned a threat ranking and then a human security analyst can act appropriately on it.

In the case of GCSS-Army, if metadata on the status of each individual vehicle was somehow automatically reported to GCSS-Army, vehicles could be effectively maintained at a much faster rate. Vehicles in the civilian sector have self-reporting computers that consistently report deficiencies and alert operators if those deficiencies become hazardous. It would be ideal to have a computer that maintains uplink capabilities within each military vehicle, self-reports maintenance deficiencies, and uploads the information directly to GCSS-Army. The computer would autonomously report potential faults that could affect the mission. This type of technology would be easy to integrate using intelligent automation protocols and rule sets to streamline the ordering of parts as the deficiencies occur.

These recommendations are just a few options to consider when it comes to implementing intelligent automation protocols for the Logistics branch. As the Army conducts and creates its baseline assessment of GCSS-Army in the next few years, it should consider how intelligent automation could save time and improve efficiency across the system. Outside of the Logistics branch, the Army has many more opportunities for integrating and piloting intelligent systems. I look forward to investigating, challenging, and writing more about potential-use cases for intelligent automation in the future.

--------------------

2nd Lt. Sameer Pandey is the executive officer of the 1113th Transportation Company, 749th Combat Sustainment Support Battalion, 224th Sustainment Brigade, in the California Army National Guard. He has a bachelor's degree in political science with a minor in technology management from the University of California, Santa Barbara, and a master's degree in public affairs and policy from the University of San Francisco. Within the civilian sector, he works as a software engineer and entrepreneur building new innovative devices to increase the capacity of the Department of Defense and the Army.

--------------------

This article is an Army Sustainment product.

Social Sharing