Customers are spending less than $20 on replacement parts to fix defective battery circuit cards in military airborne radios on the recommendation of Tobyhanna Army Depot personnel.

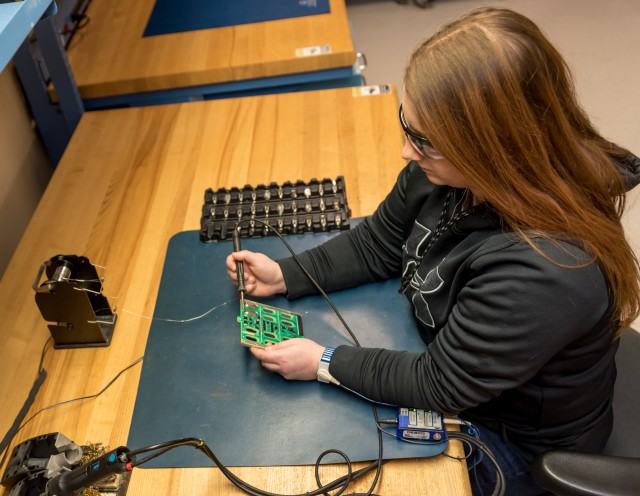

Three electronics mechanics and one writer-editor used the Army Suggestion Program to illustrate how purchasing battery cells instead of rebuilt or new circuit cards would significantly cut costs. Each circuit card contains 12 quarter-sized cells that sell for about $1.60 each, while a circuit card costs more than $1,800. First year benefits totaled more than $200,000.

Originally, faulty circuit cards were pulled from the radio system and returned to the original equipment manufacturer. As the radios aged and the batteries neared the end of their shelf life, circuit cards were failing frequently making it difficult to keep up with demand. Changing the depot's repair classification from module-level to component-level helped pave the way to increasing Soldier readiness.

"Tobyhanna has amassed a sizable backlog of systems waiting for new cards," said Mike Gerrity, electronics mechanic leader. "We knew there had to be a better way to get these systems into the hands of the users. Once we showed everyone what we were capable of program officials authorized us to start swapping out the batteries." Gerrity works in the C4ISR Directorate's Avionics Division.

It took some time to locate a suitable replacement for the obsolete battery, explained John Lywiski, electronics mechanic. Work processes were updated and documents rewritten to support the new way of doing business. Radios no longer languish on a shelf waiting for parts, they are repaired in a couple hours and returned to the warfighter, he added.

"It's important to produce quality products for the military member," Lywiski said. "This was a simple idea that made a huge difference."

Tobyhanna's Army Suggestion Program is an in-house option for employees interested in developing better ways of doing business. Simple fixes to repetitive problems often result in sustainable process improvement and better quality of life for members of the workforce. Monetary awards are based on the tangible value of suggestions.

"We didn't have schematics to go by, so figuring this stuff out was a challenge," said Electronics Mechanic Amanda Cortino, noting that as a group they were able to brainstorm about different ideas. "It's a great feeling knowing that what you're doing helps the warfighter."

Kevin Slater is excited to see the team's idea come to fruition after months of work. The writer-editor is assigned to the Production Engineering Directorate's Technical Publications Branch.

"It's nice to know depot leadership supports our ideas to improve processes," Slater said. "It was rewarding to see this suggestion result in an increase in production and a decrease in costs."

Social Sharing