WASHINGTON -- Hardly a day goes by without a very honest question being asked of the Synthetic Training Environment Cross-Functional Team: "What is the Synthetic Training Environment, or STE?"

Whether it is staffers on Capitol Hill or training capability users at a military installation, all intuitively seem to know there is something revolutionary and disruptive about the STE CFT, but they want this new "thing" described to them so they may better appreciate it.

We love getting this question, but our first task is to expand the questioner's approach to understanding it. The STE is not just another new shiny piece of technology. Not only is it part of the Army's modernization effort, it is the first holistic training strategy for the Army.

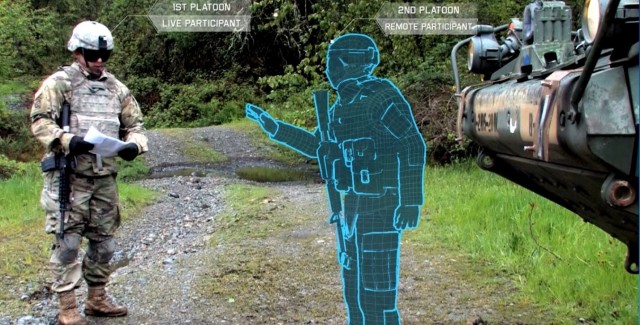

What makes the STE truly revolutionary and disruptive is the "how" as much as the "what" of it. Much like the name environment suggests, the STE is comprised of a common One World Terrain, or OWT; Training Simulation Software, or TSS; Training Management Tools, or TMT; and common user interfaces that will change the entire ecosystem of simulation training capabilities. To better understand how, we can look at another technical revolution.

THE RISE OF THE MACHINES

When imagining the period when humanity transitioned from a reliance on muscle power to machine power -- the Industrial Revolution -- it is easy to assume that technological developments, like steam engines replacing horses, constituted the totality of the revolution. However, the revolutionary part of the transition was just as much a change in the processes, or the "how" of technological development.

Simply stated, instead of just making machines to do end product work (e.g., the creation of a tractor to replace a mule team), machines were created to make other machines. The production line, therefore, fueled the Industrial Revolution just as much as the end user individual technologies it delivered. The transition from labor intensive, hand production methods to manufacturing processes gave rise to the factory system. This change enabled labor saving devices to be produced en masse, therefore making them widely accessible. In turn, the effects of new technology multiplied and enabled opportunity for further innovation, creating a truly revolutionary era.

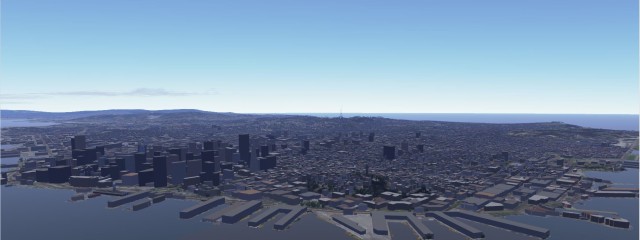

The paradigm of industrialization helps illustrate the reality that a similar revolution is taking place in our own digital and information age. The STE is part of this revolution. Consider, for example, the STE's OWT capability. In the past, simulation terrain has been painstakingly created by coders and digital artists for each simulation system, much like monks in 14th century monasteries hand writing and copying religious texts. As a result, the production and maintenance of three-dimensional simulation terrain is both incredibly costly and time consuming.

OWT revolutionizes this practice through an automated process for collecting raw digital terrain data from a multitude of preexisting sources and sensors, rectifying and correlating it to make it usable, and then storing it in a centrally accessible location for common use across 3D simulation systems.

In effect, individual scribes laboring away in digital terrain monasteries will be replaced by an automated digital terrain printing press -- not just a Gutenberg-style press, but one with the power and span of those leveraged by newspaper magnate William Randolph Hearst. Updates to open source map data, as well as uploads from squads in the field using Unmanned Aerial Vehicles, will be able to continuously add to, refine, and update the OWT global terrain database.

CIVIL WAR RAILROADS

By the middle of the 19th century, the U.S. was awash in mechanical innovation. Ever newer, faster, and more powerful locomotives were being developed. Despite the rapid innovation, the roughly one hundred railroads in the southern states did not work together as a cohesive network. More often than not, they were individually developed, and there was fierce competition between railroad owners to maintain proprietary control.

Accordingly, most railroads were comprised of short unconnected lines. Standards varied so significantly that track gauges ranged from four to six feet in width. The proprietary nature and unique standards for each railroad made efficient movement of cargo across the region nearly impossible. As the Civil War unfolded, scholars generally agree the Union's significant advantage in available miles of track, connections, and greater degree of standardization yielded superior lines of communication throughout the war. This Industrial Age example demonstrates the critical importance of common standards, interfaces, and protocols as we consider ways to maximize the benefits of our own digital revolution.

Today, echoes of the great 19th century railroad race -- furious, albeit desynchronized and unstandardized innovation -- are manifest in the similarly rapid evolution of computer and information technology. Digital technology manufacturers have employed proprietary hardware, software, interfaces and protocols to maximize to the greatest extent possible means to control and profit from their products.

From a DOD perspective, the overlay of these factors with a lengthy and complex DOD acquisition process has resulted in military training simulation systems that suffer from the same constraints as Southern Civil War-era railroads. Although similar in overarching purpose and basic design (locomotive, railcars, and tracks), most collective simulation systems were designed separately by a variety of companies for specific training purposes. As a result, they are difficult to connect, and when connected these systems cannot easily share data. These digital railroad cars run on different gauge tracks, have different types of coupling systems, and carry uniquely configured loads. With the current set of synthetic training systems, moving digital cargoes' content across systems requires simulation data to be unloaded and transferred to a different line through a variety of digitally inefficient workarounds.

The STE addresses these closed systems by developing common simulation software and interoperable hardware through standardized interface controls and protocols across the collective training environment. Using our railroad example, OWT effectively ensures a global rail (i.e. synthetic terrain) network that is accessible to all users, persistently interconnected, and constantly updated and improved. By leveraging the establishment of common standards, OWT will provide a complete representation of the globe, fully accessible through the Army network, which represents the complexities of the operational environment and the all-domain battlefield.

Additionally, the TSS capability, the STE's "game engine", provides a single training environment using open architecture and common application programming interfaces, or APIs, to deliver a centralized capability for representing and adjudicating all simulation entities (i.e. players and the units they control) and user inputs. In terms of our railroad analogy, the TSS ensures that trains run on a universal time with synchronized movement schedules, and possess the standard locomotive and railcar characteristics that make them interoperable. Further, TSS can seamlessly accommodate individual riders through corps-sized equivalent passenger manifests.

Finally, TMT provides an intuitive and easy to use application that's accessible anywhere and anytime to create training scenarios. TMT automatically retrieves and transforms authoritative data, automating the generation and population of simulation databases. In short, TMT ensures railroad clients are able to schedule cargo movement based on specific logistic needs as well as monitor and assess how effectively their cargo is being transported. For each of these tools --OWT, TSS, and TMT --the common standards, interfaces, and protocols enable all types of common user interfaces to effectively and efficiently connect to the rail system to rapidly load and unload a variety of standardized data on and off of railcars.

THE NEXT REVOLUTION

Just as manufacturing processes of machines producing machines gave rise to the Industrial Revolution, the ability to collect and make knowledge products from the sea of data (directly and indirectly produced by fully connected digital technologies) is driving a factory of factories system revolution.

The factory of factories system includes processes driven by AI, which are fundamentally algorithms, and machine learning, a predictive capability based on analysis of large data sets. The products of these processes will significantly improve Soldier workflow and training, thereby reducing Soldier cognitive loads by eliminating mundane and time intensive cognitive tasks. By automating these tasks including navigation, situational awareness, mission command, and logistics, this technology will enable faster, more informed decisions -- a critical element in achieving combat overmatch of our peer competitors. These technologies will fuel the second revolution in combat training, building upon the first with the establishment of the Combat Training Centers.

THE FUTURE IS NOW

The foundational capabilities of STE's OWT, TSS, TMT, with common user interfaces is a first critical step that will continue to deliver the foundation for technological innovation and increased capability. Automated digital processes, coupled with common standards, interfaces, and protocols, will enable an already emerging second wave of technical digital innovation leveraging AI and machine learning across digital systems. The STE is at the forefront of providing this common system of digital processes that will set the conditions for the next revolution in digital technologies. It will deliver state of the art simulation training, driving current and future innovation for not only how Soldiers train, but how they will rehearse and execute future missions. The STE is part of an ongoing digital revolution and a train we cannot afford to miss.

Social Sharing