In Korea, a captain is conducting her incoming change of command inventory. As she counts a section's equipment, she asks her platoon sergeant about the purpose of one item. The platoon sergeant replies, "Ma'am, that item is outdated, so we never use it. We just keep it in a box in the storage cage."

The supply sergeant informs her that the item is authorized on the modified table of organization and equipment (MTOE), so they cannot turn it in. The captain wonders how she can get rid of this item since it has no purpose in their day-to-day operations and training and may not be needed even in wartime operations.

Meanwhile, a battalion S-3 is observing company-level training during an exercise in Poland. He asks one of the platoon sergeants for his thoughts on the training. The platoon sergeant states that he could better accomplish the mission if he had a certain piece of equipment that he used in his last unit.

These situations have been repeated in motor pools and units around the world for many years. The Soldiers were both asking the same question: How can I change my organization's equipment authorizations?

The Army has several top-driven methods that it can use to change table of distribution and allowances (TDA) and table of organization and equipment (TOE) authorizations. However, this article provides information on how leaders can effect changes to their TDAs and TOEs from the bottom up.

ARMY PROCESSES

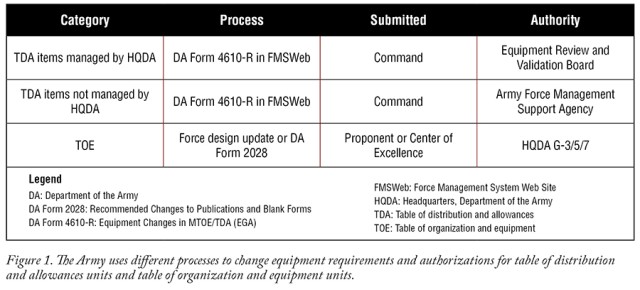

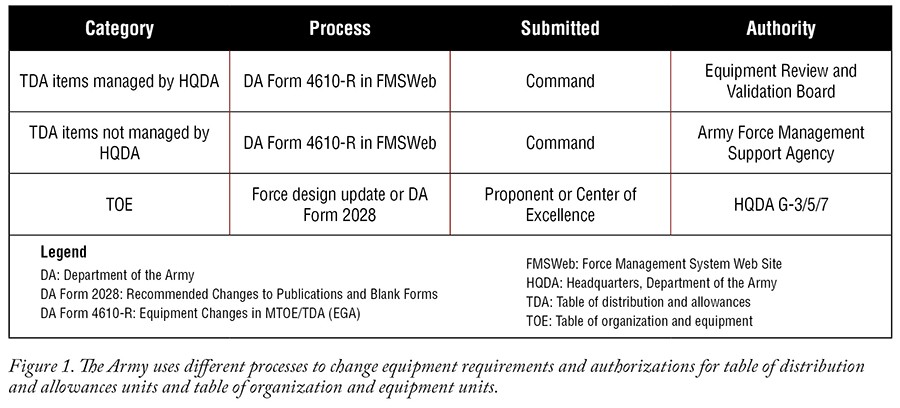

The Army uses different processes to change organizational equipment requirements and authorizations. For TDA changes, the Army uses the Department of the Army (DA) Automated 4610-R TDA Equipment Request Tool in the Force Management System Web Site (FMSWeb).

For TOE changes, it uses the force design update process or a DA Form 2028, Recommended Changes to Publications and Blank Forms. (See figure 1.) Organizational equipment changes can also be incorporated in concept plan submissions. These procedures are governed by Army Regulation 71-32, Force Development and Documentation. The processes are quite simple but have complex effects. While approvals may be timely, solutions can take a long time to complete for even the simplest, seemingly obvious change. Changing Army organizational designs is the responsibility of the centers of excellence (COEs) and branch or functional area proponents of the Training and Doctrine Command (TRADOC).

TDA UNITS

Generally, each TDA is unique, which makes the change process simpler. To begin the process, the unit submits an equipment change request through the 4610-R TDA Equipment Request Tool in FMSWeb. This tool requires a common access card to log in.

The process and guidance are outlined in the TDA/AUGTDA Unit Equipment Review and Validation Board (ERVB) Policy, which can be obtained through the "4610-R Help Desk" icon in FMSWeb and at unit G-3 or G-8 offices.

The request is then routed through the unit commander for approval. If the requested item is valued at over $1 million, a cost-benefit analysis must accompany the request. The Headquarters, DA (HQDA) Deputy Chief of Staff (DCS) G-3/5/7 Force Management Directorate provides the cost-benefit analysis tool on the ERVB Army Knowledge Online portal at https://www.us.army.mil/suite/community/25969876.

The cost includes the price of the equipment and any associated costs, such as facility improvements and estimated maintenance. The command must budget for any required life cycle costs. Once the commander approves it, the request takes one of two paths. The first path is for requests that include HQDA-managed line item numbers (LINs) that are reviewed and approved by the ERVB. These are routed electronically to the HQDA DCS G-3/5/7 Force Management Directorate for staffing.

At this point, if it is classified as a tactical wheeled vehicle request, it will go to TRADOC's Tactical Wheeled Vehicle Requirements Management Office for concurrence or non-concurrence. It then proceeds to the resourcing activity, the Army Materiel Command, HQDA DCS G-4, and HQDA DCS G-8 to see if the request can be resourced.

The request then proceeds to the ERVB council of colonels then to the general officer steering committee about two weeks later for final review and approval. It should be noted that hundreds of requests go through this process each month.

Commands are required to have a representative attend all ERVB sessions either in person or remotely to address board member questions or concerns. After each general officer steering committee meeting, a decision memorandum is distributed to submitting commands and the approved decisions are sent to the Army Force Management Support Agency (USAFMSA) to update applicable TDAs.

The TDA update process can take a week to several months based on priority. Arrival of the newly approved equipment is based on priorities and when the item will be issued from the supply source. This process does not apply to augmentation, mobilization, and joint versions of TDAs.

SECOND TDA PATH

The second path for TDA units is used when the approved command request involves LINs that are not HQDA managed, LINs that are deletions, and LINs that need to be transferred from one command to another. These requests proceed electronically to USAFMSA for action and do not go before the HQDA ERVB.

Some requests, if they meet certain criteria, can be approved by the local command with authority. USAFMSA is the approval authority for all equipment transfers. Generally, additions to the TDA for equipment on hand are favorably considered if the justification is sufficient. TDA commands retain the authority to remove any excess or unnecessary items as standalone actions without higher headquarters' approval.

In most cases, the final approval for TDA updates is the ERVB, chaired by the HQDA G-3/5/7 director of force management. This board is held 10 times a year. Each command is reviewed quarterly or semiannually, based on the average number of automated 4610-R requests that it submits each year.

Currently, only the Army National Guard, the Forces Command, TRADOC, and the Army Reserve Command are reviewed each quarter because their submission volume is more than 2,000 per year. All other commands' requests are reviewed by the ERVB semiannually.

The process works well and allows the Army to manage a significant number of requests, but it is not fast. To illustrate the number of submissions processed, as of March 8, 2018, nearly 15,000 requests were submitted for fiscal year 2019 documentation. Success rates for submissions are high as well, considering that during a one-month reporting period last summer, 8,597 TDA requests were submitted, 6,380 were approved (74 percent), and 2,217 were disapproved (26 percent). The February 2018 ERVB approved 75 percent of 556 requests.

According to USAFMSA, requests are most often disapproved because of an insufficient justification narrative or a lack of an Army sourcing solution. One reason that the process takes so much time is the amount of coordination and clarification required when the 4610-R request and property book data do not match. The HQDA staff spends a great deal of time reviewing current unit property records and contacting the unit to clarify the data.

The HQDA G-3/5/7 policy for the ERVB requires these details in the justification:

• A clear explanation of what new capability is needed and why.

• A description of any mission changes that made the new capability necessary, including who directed those changes.

• The reason that the current approved equipment is insufficient to perform the mission.

• The impact on the mission if the requested equipment is not added.

• Related training requests.

• Related maintenance requests.

Units that submit equipment requests should ensure the following:

• Tracking of the justification has command emphasis. (The justification should be added to quarterly battle rhythm briefs to ensure visibility.)

• The justification is complete and specific.

• The funding information is detailed and complete.

• The request has a general officer or senior executive service memorandum that provides a strategic assessment of the command submission.

• The quantities match in the request and in unit property books.

• The points of contact and information are current within FMSWeb and on the request.

To learn more, log into FMSWeb and download the how-to guide presentation. It details the functions available within FMSWeb and instructions to complete equipment transactions. USAFMSA also details the process during a block of instruction in quartermaster warrant officer courses at the Army Logistics University at Fort Lee, Virginia.

MTOE UNITS

TRADOC Pamphlet 71-20, Concept Development, Capabilities Determination, and Capabilities Integration, explains the process and steps for MTOE changes. The process begins with an individual developing the justification and submitting it through his or her chain of command to the division G-3 and force management officer for command review. As the request proceeds, a determination is made about whether a doctrinal capability needs to change or a particular item in a particular unit needs to change.

Once reviewed, the request is submitted to the applicable capability's COE. For example, if a change is requested to a transportation unit, the routing would be through the Sustainment COE. The key to the justification is explaining the capability gap that needs to be overcome, how the suggested addition addresses that gap, and the risks if the recommendation is not approved. The more specific the justification the better; more details will answer potential questions and reduce roadblocks. If the request is to remove an item, the requesters must explain specifically why the item is not needed and how the mission that once required that piece of equipment is now being accomplished.

The official Army form to submit a change request is the DA Form 2028, but it is not suitable for all recommendations. The commonly used option is to submit the recommendation on a standard memorandum with a specific justification and attachments.

After command approval, the staffed recommendation should be sent to the proponent or the COE's Capabilities Development and Integration Directorate for staffing. Army Regulation 5-22, The Army Force Modernization Proponent System, lists all the proponents and COEs for each branch and functional area.

At this stage, a simple idea requires a complex staffing process because any recommended change to one unit's TOE affects every unit of that type in the Army inventory. TOEs provide the minimum mission-essential wartime requirements and represent the doctrinal organization from which units within the operating force are built.

The COE decides if the change applies to all units of the same standard requirements code or if the change justifies the creation of a variant standard requirements code. The COE develops the force design update (FDU) packet and submits it to the TRADOC Army Capabilities Integration Center (ARCIC).

ARCIC then conducts an Armywide field staffing of the proposed change and determines whether to establish or reject the new requirement. If the requirement is validated, TRADOC submits the FDU to the HQDA G-3/5/7 for approval.

HQDA then conducts a force integration functional area assessment to ensure the requirement meets goals such as deployability, stationing, funding, and sustainability. This process takes approximately 90 days to complete and ends with a recommendation for approving, deferring, or returning the FDU for revision.

If approved, the changes are submitted to USAFMSA for documentation. Depending on the recommended changes and priority, it can take a year or two to complete the documentation.

TIME CONSIDERATIONS

So what makes the process so long? Deliberate process changes are driven by Total Army Analysis and programming budget process timelines. Organizational changes to be implemented in the 2022 to 2026 time frame need to be submitted to HQDA by October 2018.

There are two other options for FDUs. If operational needs dictate, or at the discretion of Army senior leaders, an out-of-cycle FDU may be submitted to handle complex design issues or special issues. An example of this is a study of a new reconnaissance and security strike group that was directed by the chief of staff of the Army.

An FDU junior is a faster process than a regular FDU and can be submitted at any time. It involves minor adjustments to designs that normally do not affect other proponents and do not contain personnel changes.

Feedback from two COEs indicate that most of the inputs for TOE changes come from lessons learned briefings, senior leaders, and feedback from commands. COEs process 20 to 30 FDUs a year, and each takes approximately six to 12 months to process. The COEs receive many ideas, but not all are executable for a variety of reasons.

USAFMSA recommends that units submit change requests through their chains of command to the division G-7 or equivalent. Each request should be assigned a tracking number that can be referenced.

The brigade commander can assist with this process by requesting that the division (or general officer-level command) G-7 post status updates of pending change recommendations on its portal and include updates in the division or corps materiel management reviews for visibility. Without a tracking mechanism and command emphasis, change recommendations will not have the necessary visibility to succeed.

Leaders at all levels should work with their organizations to recommend changes. They should justify their recommendations and lead the change to prepare their units for the future. These processes take time, but individuals should submit changes they believe can improve the organization, even if they will not be in the unit to see them through to completion.

So, for our new commander in Korea and the battalion S-3 in Poland, there is a process to implement their good ideas. It just takes one critical-thinking professional to start the ball rolling. Efforts are ongoing at the HQDA G-3/5/7 and USAFMSA to reduce the time and effort needed to submit, receive, and approve requests from Army commands.

--------------------

James L. Kennedy Jr. is a retired Army colonel and an assistant professor at the Command and General Staff College campus at Fort Belvoir, Virginia, where he teaches force management and sustainment. He holds a bachelor's degree in chemistry from Presbyterian College, a master's degree in logistics management from the Florida Institute of Technology, and a master's degree military history from the Command and General Staff College. He is pursuing a master of education degree from George Mason University.

The author would like to thank ARCIC, USAFMSA, the Combined Arms Support Command, and HQDA for providing input to this article.

--------------------

This article was published in the May-June 2018 issue of Army Sustainment magazine.

Related Links:

Army Sustainment Magazine Archives

Social Sharing