FORT RUCKER, Ala. (January 30, 2018) - Material handling mishaps are a leading cause of Department of the Army Civilian injuries. Annually, there are about 2,300 DAC injury claims submitted at a cost of nearly $50 million. Material handling mishaps can result in disability or even death.

"When it comes to material and equipment handling mishaps, the cost to Army readiness and our workforce's wellness is substantial," said Rachel Baccigalopi, safety and occupational health specialist, USACRC Workplace Safety Division. "The bottom line is these injuries are preventable."

After conducting a trend analysis using Defense Injury and Unemployment Compensation System data, the Workplace Safety Division identified material handling as a primary cause of injury based on workers' compensation claims.

"As a result of our findings, we (USACRC) developed a training support package, with supporting videos that demonstrate proper lifting techniques, to provide an additional mishap prevention resource to our stakeholders across the Army," Baccigalopi said. "The TSP addresses specifics of mishap categories to include common causes of material handling injuries, top injury outcomes, occupations that have the most injuries due to material handling and the prevention of these types of injuries."

While material handling injuries are a top cause of DAC injuries, Baccigalopi cautions that Soldiers should be mindful of these injuries as well.

"Most organizations around the Army have some degree of material handling occurring," she said. "Often our Soldiers work side-by-side with their civilian counterparts and are exposed to the same hazards. It can be as simple as carrying a box of printer paper back to an office or as complex as working in a location with extensive industrial operations."

Following a few guidelines could be key to reducing these injuries within an organization. Baccigalopi encourages supervisors to conduct job hazard analysis and to secure material handling equipment whenever possible.

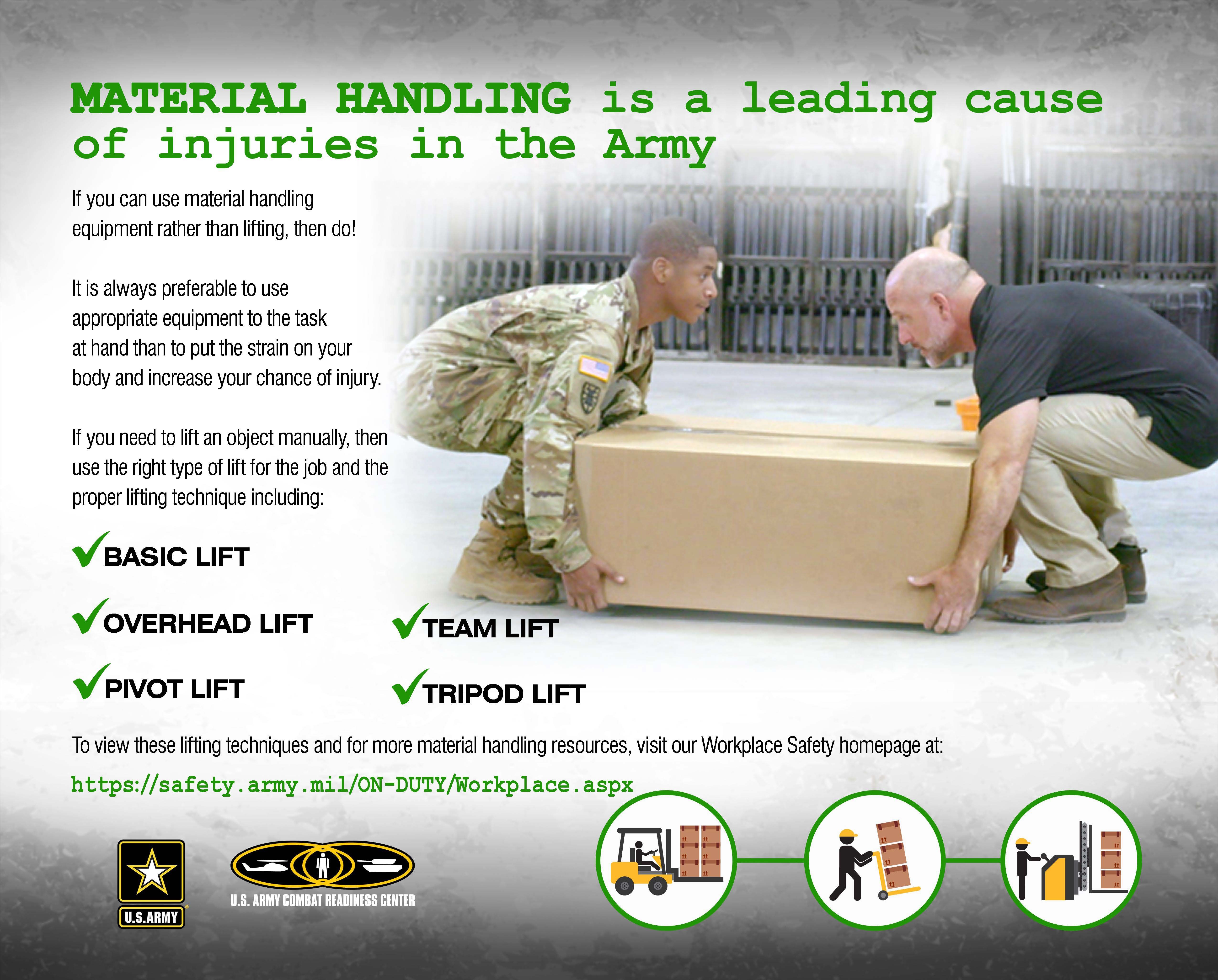

"If someone can use material handling equipment rather than lifting, then they should do so," she said. It is always preferable for the workforce to use appropriate equipment for the task rather than putting a strain on their bodies and increasing the risk of injury.

"Incorporating and enforcing the proper lifting techniques demonstrated in this training (TSP) into existing safety programs will pay huge dividends, not only in a singular organization, but across our Army."

Related Links:

U.S. Army Combat Readiness Center homepage

USACRC Workplace Safety homepage

Social Sharing