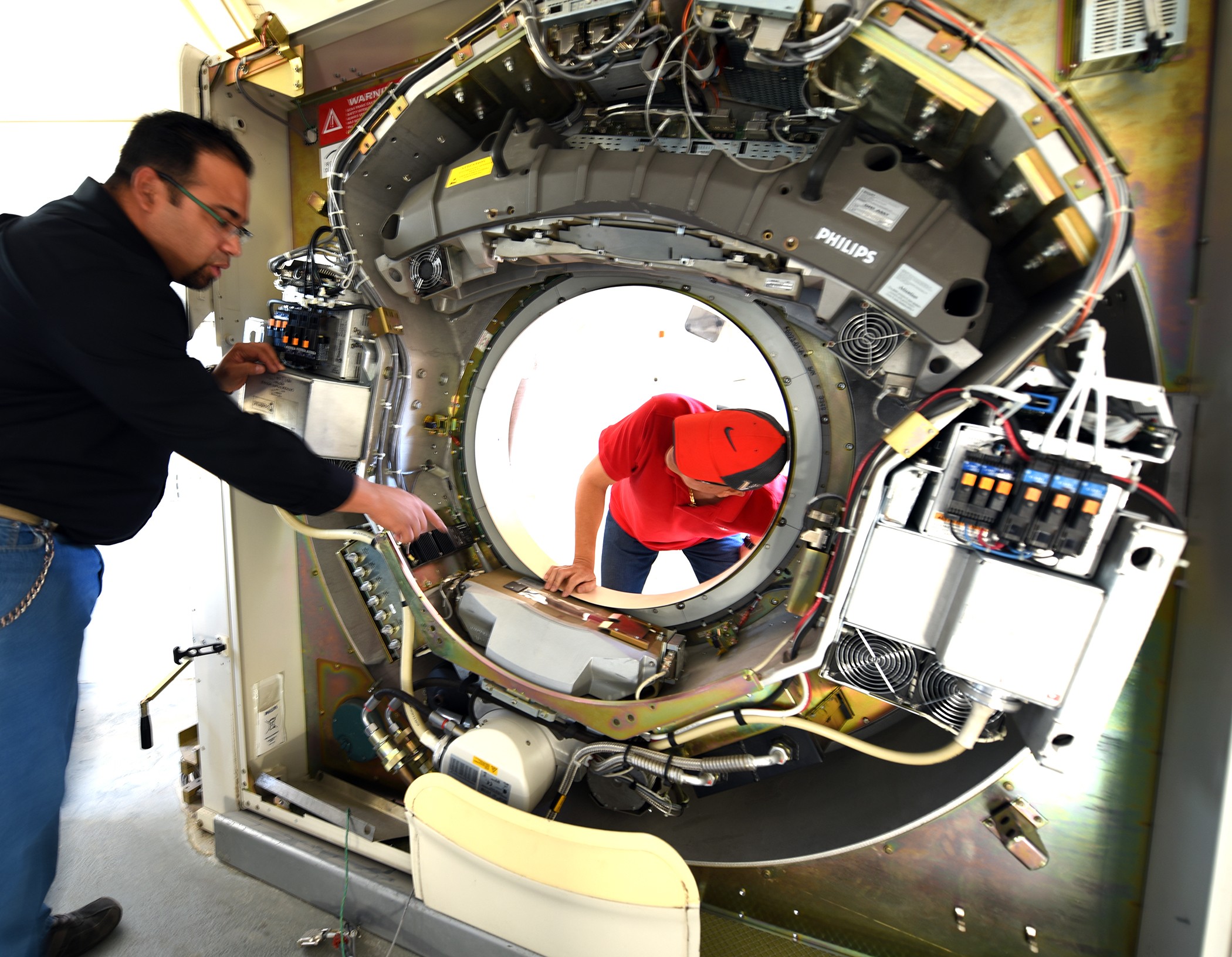

When a computerized tomography system arrives at Medical Maintenance Operations Division-Tracy, it often looks like it has been to war -- because it has.

Despite looking a bit rough, these systems are still worth millions of dollars. So they are sent to the depot where they get a second life or, in some cases, a third or fourth life.

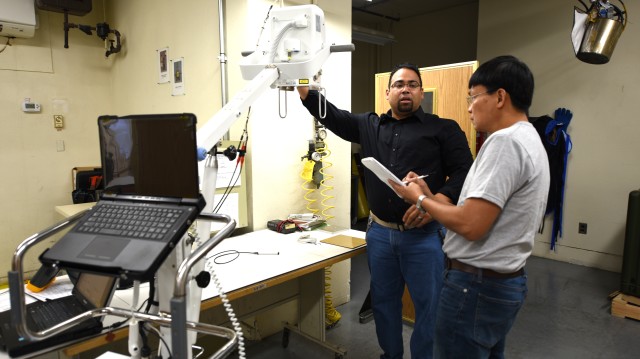

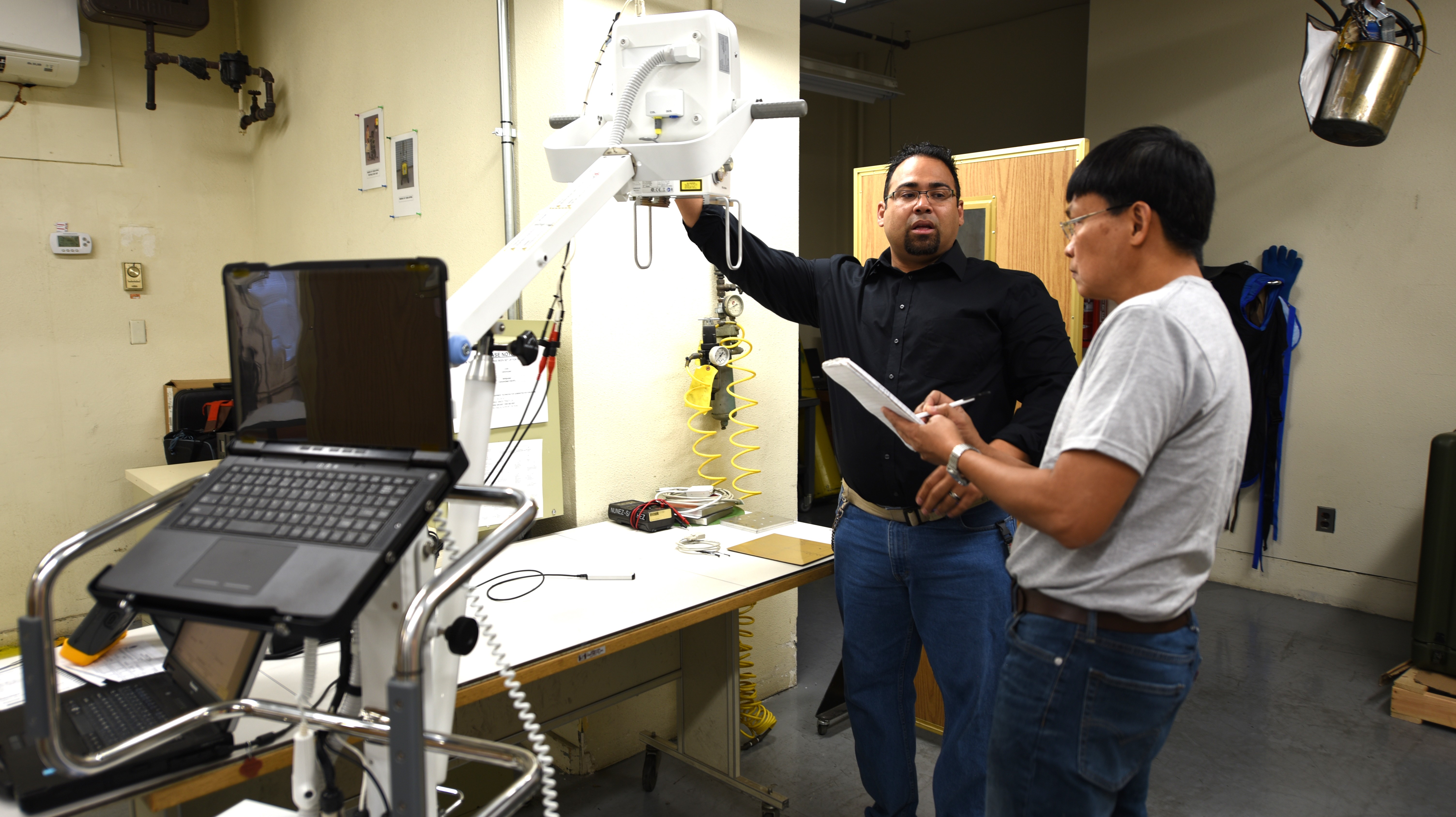

MMOD-Tracy, located on Defense Distribution Depot San Joaquin, California, is one of three stateside medical maintenance depots that operate under the U.S. Army Medical Materiel Agency, a subordinate organization of the U.S. Army Medical Research and Materiel Command. As part of the Army's organic industrial base, MMOD-Tracy serves as the Center of Excellence for medical imaging equipment, special purpose test, measurement and diagnostics equipment and the Army Medicine X-ray acceptance program.

Additionally, MMOD-Hill at Hill Air Force in Utah is the Center of Excellence for anesthesia, pulmonary and field medical equipment. MMOD-Tobyhanna in Pennsylvania is the Center of Excellence for audiometer calibration, optical equipment, dental hand-piece rebuild, the Military Entrance Processing Station Direct Exchange program and Table of Organization and Equipment lab equipment.

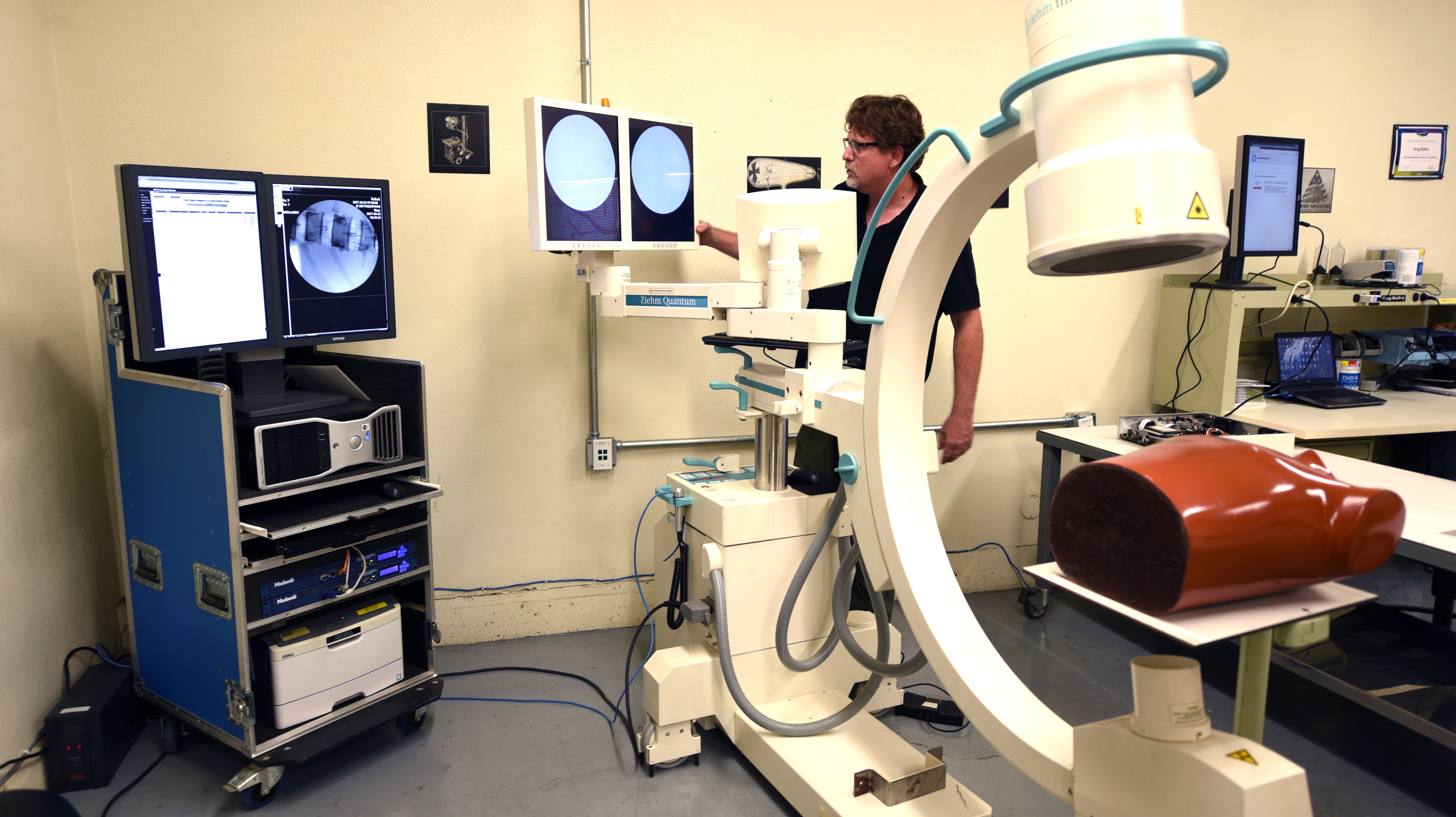

Besides testing, calibrating and conducting depot-level maintenance, highly skilled and trained biomedical equipment specialists at each depot refurbish medical equipment, such as CT scanners, so these devices can go back out to the field for use. After recapitalization, these pieces of equipment are like new or near "zero-time/zero-mile," extending their overall lifespan and providing critical training to the depot teams.

It is an investment of time and money to recapitalize; however, the return on investment proves it is worth it. USAMMA spends approximately $2.3 million annually to recapitalize more than a 1,000 medical equipment items with an acquisition value, or cost to buy new, of more than $12 million. That means USAMMA's annual recapitalization efforts generate an estimated annual cost savings for the Army of almost $10 million. Approximately half of that cost savings is attributed to recapitalization efforts on imaging systems resulting in a savings of approximately $4.5 million in 2017.

"We try to do this because it is cost effective for the government," said Curtis Randolph, chief of MMOD-Tracy. "It also means we can turn the equipment around faster and get it back to the user."

Randolph, who has served the Army for 35 years both on active duty and as a civilian, explained that getting the equipment back out to the field delivers something even more valuable than cost savings-- the potential to save lives.

"Some of us are retired Veterans and others are reservists," added Randolph. "We know that what we do directly affects patient care."

Social Sharing