NATICK, Mass. -- Sometimes a great idea just gels.

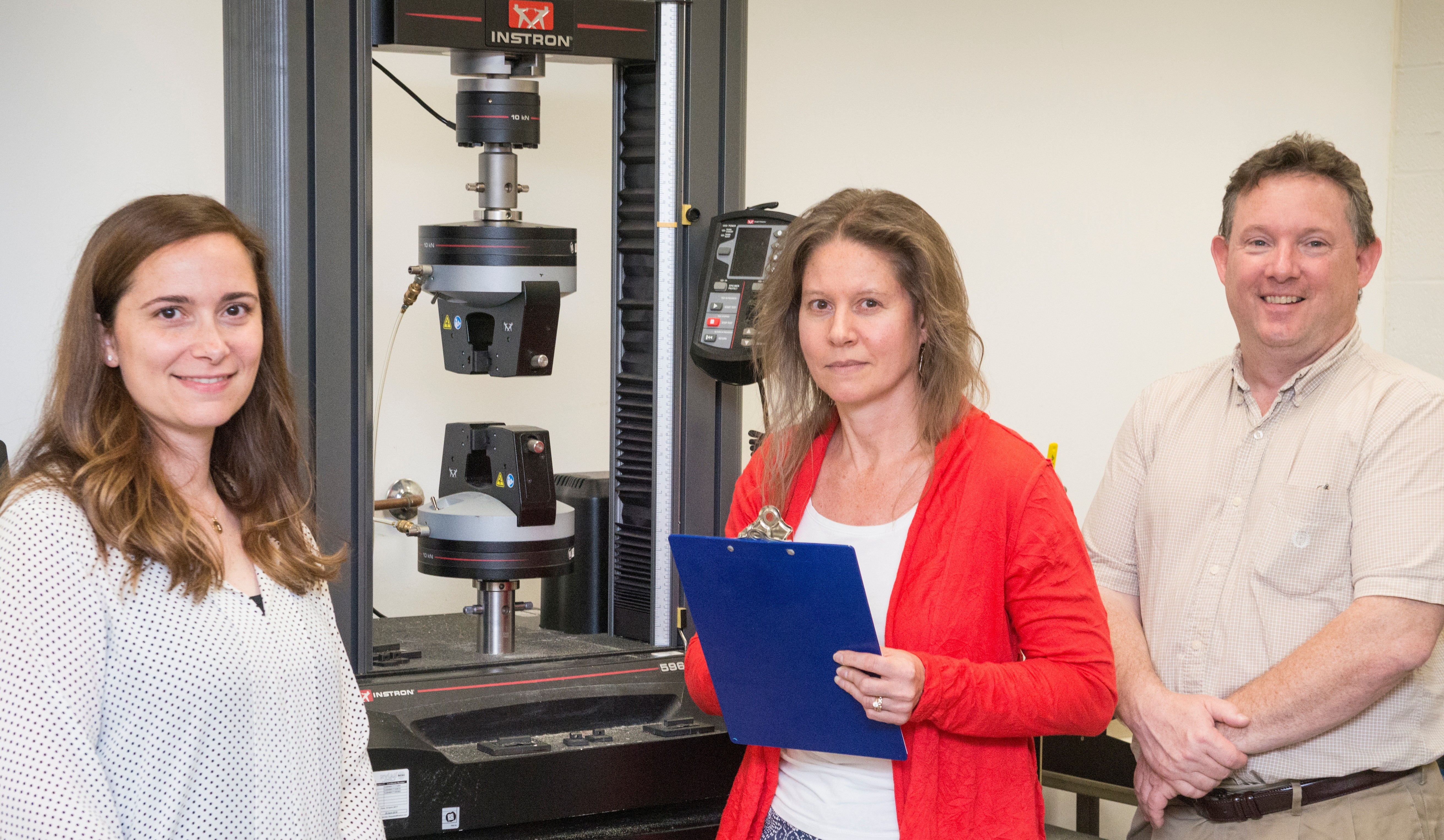

Dr. Chris Doona -- a senior research chemist at the Natick Soldier Research, Development and Engineering Center, or NSRDEC -- is working with superabsorbent hydrogels and chlorine dioxide disinfectant to prevent mold and mildew growth that can damage and degrade textiles.

Currently, Doona is focusing on mold and mildew issues affecting cotton parachute sleeves, a problem brought to his attention through NSRDEC's Bootstrap Initiative.

NSRDEC's Dr. Ken Desabrais, a research aerospace engineer, conceived the Bootstrap Initiative, which was implemented to encourage out-of-the-box thinking, promote risk-taking and enable employee participation -- all while streamlining processes and minimizing bureaucracy.

The initiative brought together Doona and Christine Charette, a textile technologist in NSRDEC's Aerial Delivery Directorate.

"The Bootstrap program really enabled this connection to happen," said Charette. "Bootstrap enabled a potential solution, as well as funding, to be found."

Doona thought the superabsorbent hydrogel-disinfectant might work with a problem that affects deployment sleeves used on the T-11 Personnel Parachute System.

"This is an identifiable, mission-related problem and the Bootstrap Initiative helped establish the connection and inspire innovation," said Doona.

"The sleeve is critical in the T-11 deployment process," said Charette. "As the parachute inflates, it takes less than one second for this 21-foot sleeve to be pushed off the canopy. If the nylon parachute were packed into a sleeve made from synthetic fibers like nylon or polyester, tremendous friction would occur that could damage the parachute as it rapidly deploys. Using cotton reduces the level of friction and prevents that type of damage from happening."

Charette explained the reduction in friction is why cotton was, and is, the optimal fabric choice for the sleeve.

"Cotton was the traditional fiber choice for the sleeve, and cotton is still the best choice of fiber for the sleeve today," said Charette. "But when the cotton sleeve gets wet and is not dried quickly, it molds. This is where Doona's idea comes in. Instead of a complex textile material or a major design change, these superabsorbent hydrogel-disinfectant pads can be placed right in the kit bag post-jump, right on the drop zone. That will help mitigate mold growth on the wet equipment during transport back to the unit, until the equipment can be dried properly."

"We observed that the superabsorbent hydrogel/chlorine dioxide system could prevent mold on berries," said Doona. "So, we thought it might work in preventing mold on textiles such as parachute sleeves, shelters and tents and vehicle mats. It could potentially help any product -- textiles, leather boots and shoes, wood -- that is prone to mold during storage in wet or humid environments, especially where temperature fluctuates."

Doona has invented an ensemble of mixed chemical technologies that have been used in numerous applications, to sterilize surgical instruments, decontaminate textiles, sanitize hard surfaces and recycle gray water. Using a superabsorbent hydrogel helped Doona create a humidity-controlled, time-released method to generate chlorine dioxide at low levels inside containers to prevent mold growth on fresh fruits and vegetables, as well as other plants and flowers.

The senior chemist is well known for his research. For his accomplishments at Natick, Doona was awarded the Institute of Food Technologists' 2017 Food Technology Industrial Scientist Achievement Award, a prestigious honor from the world's largest food science organization that recognizes significant contributions to advance the science of food. It is the first-ever such award earned by a Natick scientist.

Doona's decision to apply the superabsorbent hydrogel-chlorine dioxide concept to textiles comes from a long history at Natick of addressing mold issues for Soldiers.

"Natick Hall of Fame microbiologist Dr. Elwyn Reese, who worked at Natick from 1954 to 1972, pioneered research with the eponymous Trichoderma reesei, a fungi that degraded U.S. Army tents in the Solomon Islands during World War II," said Doona.

Both Doona and Charette are dedicated to improving quality of life and safety of the Soldier.

"I'm very excited that this is something we can do to help fix a problem that Soldiers face," said Charette. "I'm so glad we made this connection inside Natick, and, hopefully, we can solve the problem. I'm looking forward to the results."

"To be a research chemist, and to be innovative while solving real-world problems, presents a lot of great opportunities," said Doona. "It helps make Natick a particularly compelling environment with great interactions internally between teams within Natick, and externally with universities such as MIT and Brandeis, as well as with small companies who license and commercialize our inventions. I want to see my research get to the field and help the Soldier and the country, like it did during the Ebola crisis."

Doona's inventions were fielded during the crisis in West Africa to sterilize medical equipment by health care professionals from the World Health Organization, National Institutes of Health and Public Health Canada.

The technologies developed by Doona also benefit the civilian population through NSRDEC's ongoing success in transferring useful technologies to the commercial sector. Many of Doona's inventions have already been licensed to industry, resulting in a commercial product.

The innovative use of superabsorbent hydrogels and chlorine disinfectant has already sparked commercial interest.

"We do have interest from private companies in our latest invention for automotive and shipping applications," said Doona. "It's versatile and has a lot of potential."

---

The U.S. Army Natick Soldier Research, Development and Engineering Center is part of the U.S. Army Research, Development and Engineering Command, which has the mission to provide innovative research, development and engineering to produce capabilities for decisive overmatch to the Army against the complexities of the current and future operating environments in support of the Joint Warfighter and the Nation. RDECOM is a major subordinate command of the U.S. Army Materiel Command.

Related Links:

U.S. Army Natick Soldier Research, Development and Engineering Center

Social Sharing