Locations on Joint Base Myer-Henderson Hall are named for people that have made significant contributions to the legacy of the 3d U.S. Infantry Regiment (The Old Guard). Summerall Field, Whipple Field and Folland Hall are all examples of places that honor Soldiers.

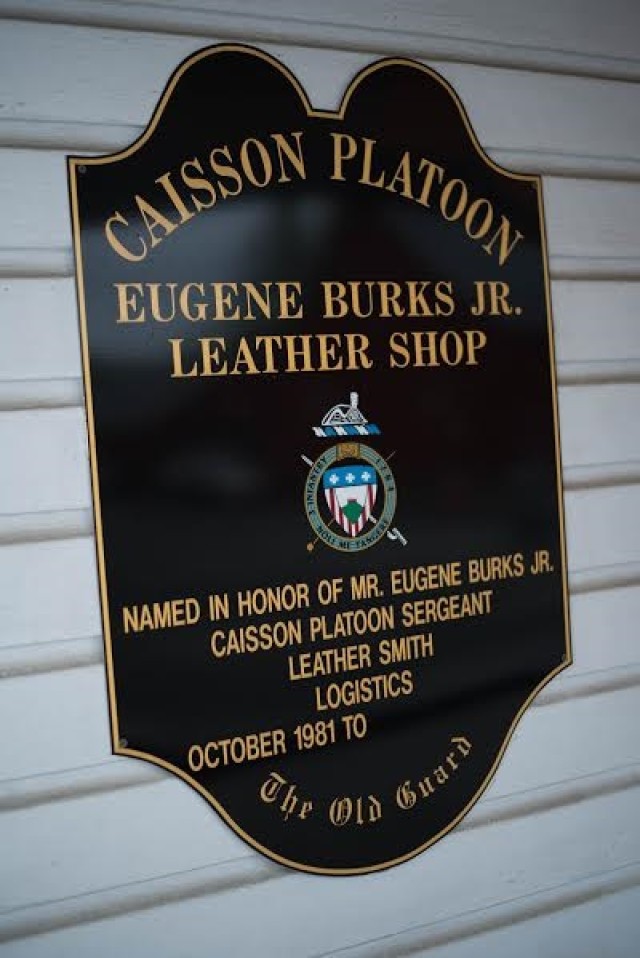

Most examples are named posthumously. However, at the Eugene Burks Jr. Leather Shop, one can find the namesake not only on the sign but working inside the shop.

Burks was first assigned to The Old Guard in 1981. Burks held many positions in the 15 years he was assigned to the Caisson including saddler, stable manager, and finally as the platoon sergeant.

After retiring from the Army in 1996, Burks was brought back as a civilian employee the following year to perform the same role he held as a Solider.

burks-7-of-8For 35 years, Burks has manufactured and maintained the 1916 horse tack. Horse tack is defined as pieces of equipment or accessories equipped on horses. Saddles,bridles, stirrups, reins, harnesses, and breastplates are examples of horse tack.

"We outfit all the horses, all their harnesses, tack, inventory, tack maintenance, or teach how to do the tack maintenance and how to do the proper adjustments for the tack every morning before they go out into the burks-5-of-8cemetery," said Burks. "We also handle all of the logistics and supplies needed for us to function."

Burk's leather shop orders all of the hay, shavings, grain, and handles all of the contracts for the Caisson Platoon.

Before arriving, Burks had never built a saddle, but wasn't new to manufacturing.

"I had some experience with sewing machines and fabrication, because my MOS (military occupational specialty) was 43K, which was canvas and light textile repair," said Burks. "We actually made and repaired tents, at that time gamma go (vehicle) covers, clothing."

Learning to sew from his grandmother at an early age helped prepare him for his job in the Army. Burks first sewed uniforms, nametags, patches, class "A" (dress) uniforms and shoes.

Burk's grandmother was a dressmaker. From her, Burks learned how to cut out patterns when manufacturing.

The only difference is instead of fabric, Burks would be creating with leather.

Before Burks arrived to The Old Guard, infantry Soldiers were performing the duty. He was the first Soldier with his MOS assigned to the unit.

Since Soldiers are reassigned so often, creating a standard was nearly impossible. Every time a Soldier left, he brought all of his skills with him, said Burks.

So when he arrived, Burks was given a limited amount of training and everything else had to be self-taught, Burks added.

burks-2-of-8Contracts with various vendors would lead to variations in the type of tack used, said Burks. A turning point came in the mid-1990's.

"About 20 years ago or so, one of the warrant officers came across the microfiche of the original 1916 equipment," continued Burks. "That allowed us to standardize everything that we use."

Everything from the stitch count, thickness of the leather and the dimensions of hardware is derived from the original 1916 schematics, said Burks.

Keeping the tack in near perfect shape for memorial affairs missions demands constant upkeep. Many pieces that would be usable in most instances are replaced to meet the high standard of The Old Guard, Burks added.

"He's always out there inspecting the tack," said Caisson Solider Spc. Robert Wilcher. "If you ever need anything, he's always on point with getting it fixed as quickly as possible."

Caisson Soldiers admire his attention to detail.

"Anytime we need anything done to the saddles, paired on the saddles, he's always the guy that you go to," said Wilcher. "He knows how to work with them, how to size them, any care that has to be done."

All of the adjustments Burks makes to the tack come from the original 1916 manual. The burks-3-of-8adjustments ensure the horses are safe from injuries from the equipment rubbing their skin raw, continued Burks.

Burks instructs Soldiers during the Basic Horsemanship course which covers the basics of maintaining the tack.

Riders will in most cases spend more time cleaning their tack than riding, said Burks.

"Shining a lot of brass, spit-shining the saddles." Burks added.

The tack is used in literally thousands of missions over the years. The saddles are present at every funeral. Burks takes his contribution to every funeral seriously. "My biggest thing is making sure when these guys leave out of here (stable), they are the absolute best as they can be as far as appearance," said Burks. "I take a lot of pride in what I do. I really believe in tradition and history."

Passing on his vast knowledge that exceeds over 30 years of experience is also a priority. He will teach as much as someone is willing to listen. That can range from tack, to just being a Soldier in general. Burks will not steer them wrong, he added.

"Working with young men, encouraging and teaching them not just about tack, but about life," said Burks. "I think I'm very good at it."

Burks said he feels this is his calling.

Burks hopes to retire in the next 2-3 years. But he will only retire once he feels his successor can handle the responsibilities.

Burks wants his legacy to carry on beyond just his name on the sign.

"The job of repairing the tack and designing, that's nothing. We can do that all day," said Burks. "But being consistent and dedicated, and believing in what you are telling them, trusting these manuals."

"I want to have somebody that is going to know why we do what we do. Once you lose history like that, its gone," said Burks.

Social Sharing