HONOLULU-Tripler Army Medical Center's (TAMC) Orthotic and Prosthetic Facility (OPF), often referred to as the "Brace Shop", provides Soldiers and beneficiaries custom made orthotic and prosthetic devices.

The OPF, part of Tripler's Orthopedic Department, treats patients through their out-patient clinic and fabricates devices in the machine shop which is located in the same space.

TAMC's OPF serves beneficiaries throughout the Pacific region and provides quality care using advanced technology to ensure patients are provided with the most sophisticated prosthetics.

The medical facilities and treatment programs at TAMC, including the OPF, are in-line with industry standards and are competitive with private medical facilities.

OPF uses state-of-the-art equipment to fabricate and fit prosthetic devices for all parts of the human body.

However, the creation of these "works of art" still requires the skills and knowledge of an orthotist.

Elton Bacon, Orthotist, TAMC OPF, has been helping patients since the early 1970s.

He began his career as a Soldier and is now TAMC's resident artist.

"I have seen the changes and advancements over the years as the field has transitioned from molding silastic and leather devices to vacuum forming thermoset and thermo-formable materials," stated Bacon. "Other cutting edge materials typically used to form prosthetics include graphite, kevlar, thermoplastic resins and even stainless steel," added Bacon.

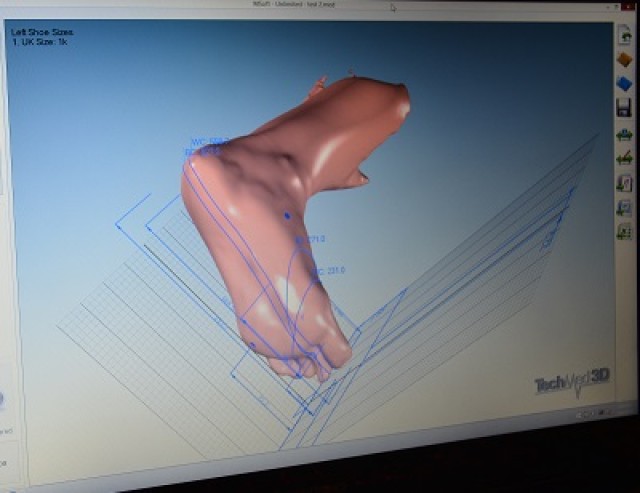

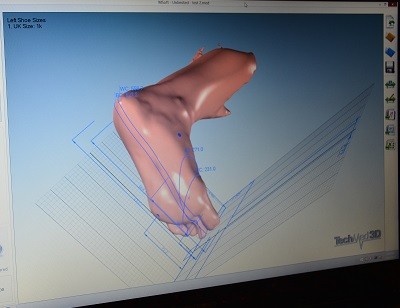

Bacon now uses computer aided design-computer aided milling (CAD-CAM) technology along with advancements in software to create his works of art.

The days of using plaster and molding are in the past.

"These advancements in technology enhance patient satisfaction and can greatly improve the quality of life for a Soldier, or a Soldier-athlete who often requires special custom molded arch supports, or an adolescent who requires a spinal brace for scoliosis or a retiree who needs a foot prostheses or post-amputation leg," states Dr. Craig Bottoni, Chief, TAMC Orthopedic Department.

Advancements in technology have also allowed masters of their craft, people like Bacon, a way to produce a cleaner and more accurate prosthetic in a shorter amount of time.

The patients not only benefit from a better fit, but with a lighter product.

Using three dimensional technology orthotists can modify and adjust live scans of various body sections of patients.

The scans are then sent to the CAD-CAM machine to create the cast of a custom fit prosthetic for the patient.

Patient privacy is also preserved.

The information used to produce an individual's cast is stored in a computer, with encrypted files, which eliminates the need to store a physical model for future use.

TAMC is continually working to broaden its services-looking for new ways to make prosthetics even more efficient and dynamic to ensure all beneficiaries get the best care possible.

Social Sharing